Focuses On Professional Cleanroom Project And Pharmaceutical Cleanroom Equipment.

BOV Pharmaceutical Industries Clean Room

Industry:Pharmaceutical Industry

Location:Saudi Arabia

Project SQM: 500

Year of Execution:2021

When we received the inquiry from our customers, we were very happy because at that time we had already completed two projects in Saudi Arabia. Our client just needs a company with experience in Saudi Arabia to complete the turnkey project. The pharmaceutical industry factory includes a custom-designed cleanroom core area for producing Bag on valve(BOV) drugs.It’s new kind of modern, innovative packaging products, such as Wound Cleansing Sprays, Saline/Seawater Nasal Sprays, Eye Wash Sprays,Ear Sprays.

Custom clean room of different heights

The cleanroom core area including 4 heights from 2.5m, 2.8m, 3m, 4m. Due to filling machinery is higher, so the cleanroom height is higher than standard 2.5m or 2.8m. It require 4m height to contain the machine. Our panels height can be customize more than 6 meters.

Usually the filter is replaced from the inside of the clean room,but customers have higher requirements for replacing the filter, which must be removed from the top for replacement. Therefore, when we communicate with customers, we design the following drawing and make a sample of round hepa box.Our engineer create a easy installation method.The drawing shows the position,this will be easier for installation too.

Customer could replace the hepa box from the ceiling side, rather than inside clean room.

Due to hepa box and led light is install and replace from the ceiling,when install the ceiling panel, customer must consider the hepa box and led light together. Cooperate with the roof facilities, and proceed simultaneously.

In the R&D and experiment cleanroom, the negative pressure weighing booth, dispensing booth and the pass box (transfer window) are indispensable equipment. The negative pressure weighing booth is usually used for powder weighing. The operating table is made of stainless steel 304, and the surface is designed with perforations to allow the powder to fall off.

Protecting the operator in a negative pressure environment.

The dynamic pass box is used for the transfer of items from non-clean area to clean area. The interior material is made of stainless steel 316, external is stainless steel 304. It’s controlled by a microcomputer and is easy to operate. The built-in design improves the air tightness and aesthetics of the pass box.

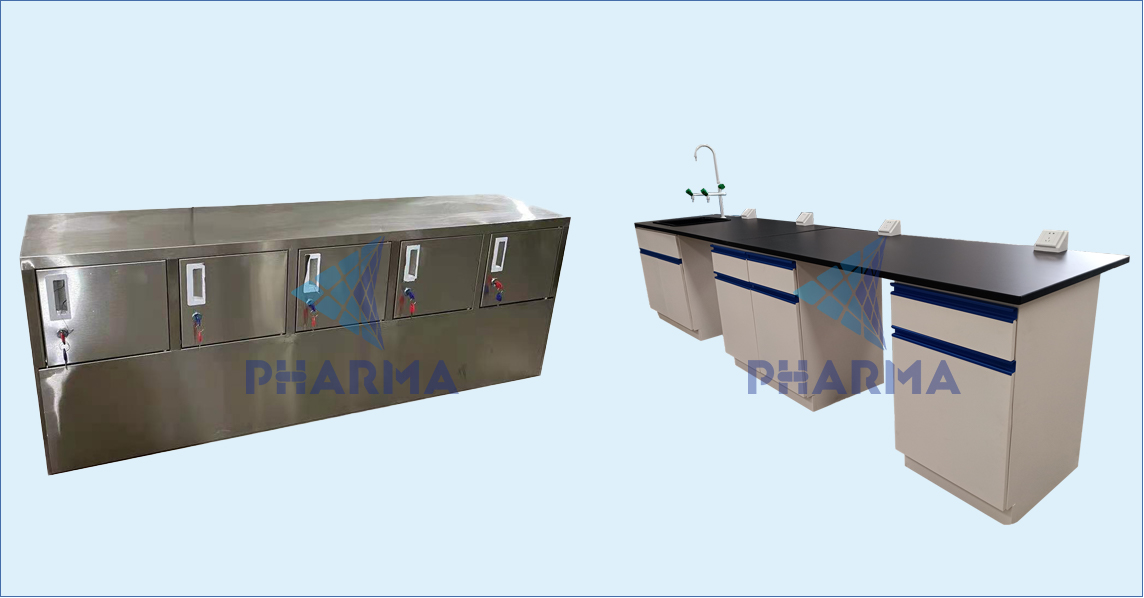

Stainless steel 304 locker, shoes cabinet, wash basin, disinfecting hand sanitizer, and experimental workbench are used in changing room and R&D laboratory. The dimension can be customize as customer request.

The development of clean rooms is closely related to modern industry and cutting-edge technology. It is used in many industries such as electronic information, semiconductor, optoelectronics, precision manufacturing, medicine and health, bioengineering, aerospace, automotive spraying, etc., and according to the industry's requirements for precision and dust-free, the level difference is also large.

At present, the highest level is undoubtedly the aerospace warehouse, which belongs to the professional field and covers a relatively small area. In addition, biochemical laboratories and high-precision nano-material production workshops also have higher requirements. The development of semiconductor chips will be a major direction of future demand.

If you want to build a clean room project and need professional solution, welcome to negotiate with us.

Suzhou Pharma Machinery Co.,LTD

2021/12/10

Spencer