Focuses On Professional Cleanroom Project And Pharmaceutical Cleanroom Equipment.

What is Modular clean room?

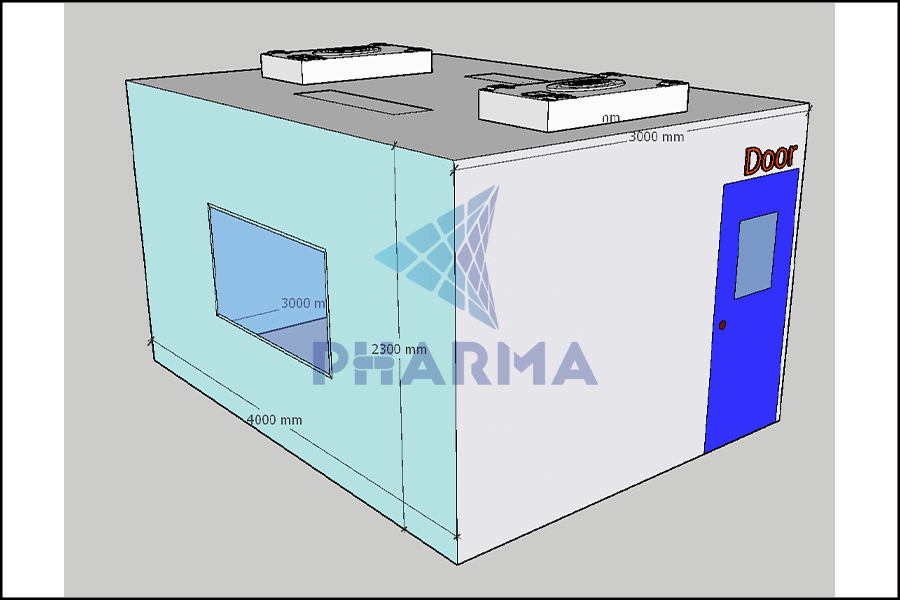

Modular cleanroom is an efficient clean space that is quickly assembled using modular components. Its core lies in the flexible combination of standardized modules (such as walls, ceilings, floors, ventilation systems, etc.) to meet different cleanroom grades and functional requirements.

The modular design supports rapid installation, disassembly and reconfiguration, adapting to changes in production requirements. Expandable clean areas can be created, or the layout can be adjusted to meet the process flow needs. It is equipped with FFU, temperature and humidity control systems, return air systems, etc., to ensure air quality and environmental stability.

The materials can be reused (over 98%), reducing resource waste.

Clean booth is a kind of equipment for creating a local high-level clean environment. Through the supply of air by the FFU and the filtration system, it can quickly establish a small clean area in an ordinary environment. It is often used as a supplement to traditional clean rooms and is employed in scenarios requiring local high cleanliness levels.

The installation period is short (usually 1-3 days), suitable for temporary or short-term needs. The material cost is low, suitable for scenarios with limited budgets.

Frame: Industrial aluminum profiles, lightweight and easy to install.

Enclosure: Anti-static curtains, acrylic sheets or tempered glass, with good light transmittance.

It can be hung, supported on the ground or moved with universal wheels, adaptable to various space layouts.

SZ-Pharma Advantages:

Suzhou Pharma specializes in providing high-quality modular cleanroom and clean booth, which are widely applied in fields such as pharmaceuticals, food processing, production and assembly of disposable syringes, filling machines and packaging machines workshop. Whether it is providing precise local clean environments (clean booth) for critical process areas, or constructing complete controlled production spaces (modular cleanrooms), we can offer solutions that meet strict cleanliness levels (such as ISO 5 to ISO 8 cleanliness), effectively controlling particle and microbial contamination. We offer a full-cycle service ranging from design planning, installation and commissioning to after-sales maintenance. With our technical strength and customization capabilities, we help enterprises enhance production efficiency and ensure product quality. Through rapid delivery and sustainable upgrades, we provide long-term and reliable guarantees for the construction of customers' clean environments.