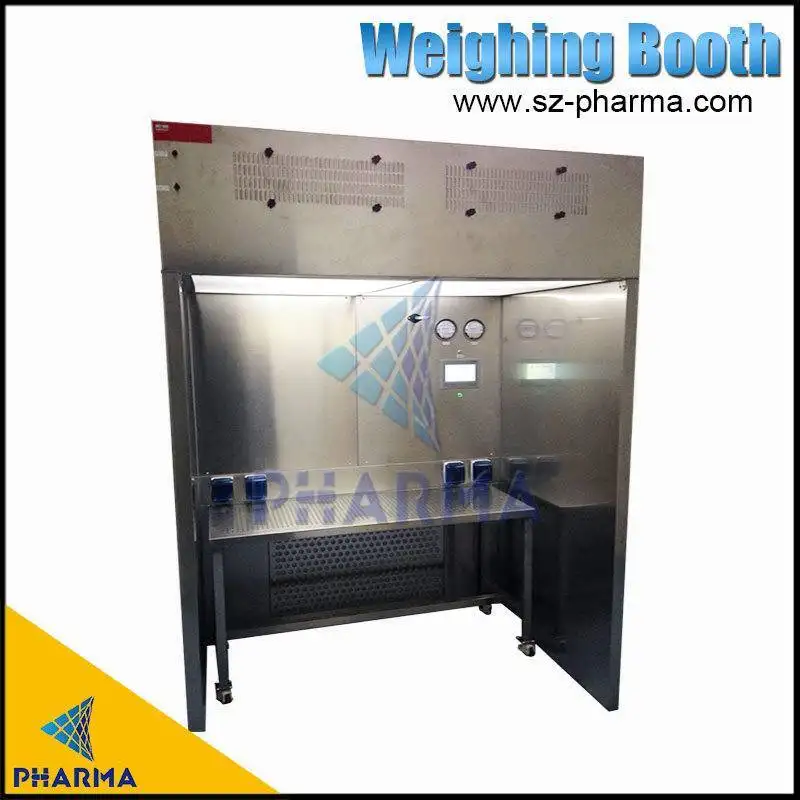

Clean Room Weighing Sampling Booth PH-W1800

Service:Video technical support, Online support, Field maintenance

Warranty:1 year

Certification:CE

Usage:Hospital/Pharmacy/Medical/workshop

Wall:Stainless steel 304, PVC curtain

Lighting:LED light, UV light

Clean grade:Class100

Name:Dispensing booth

Power Supply:AC 380V 3 phase

Filter: G4,F6, H14

Limit Discounts

Description

Dispensing / Sampling / Weighting booth is purifying apparatus. Unidirectional vertical laminar flow Class ISO5. The Raw materials and compounds are refilling, weighing, filling, and sampling inside this clean room booth. It is provided with high efficiency HEPA filter, which averts the airborne dusts by down flow of air technique. The unit eliminates powder contamination to protect the operator and the surrounding environment. It removes powder contamination in order to protect the operator and the nearby environment and is used for weighing, mixing and dispensing of powder. The sampling booth / dispensing booth is the re-circulation of air principle.

Dispensing and weighing booth is used in all industries where sterility of air is of paramount importance: medicine, pharmaceuticals, food industry, laboratory and scientific activities. Dispensing booth is located inside existing cleanroom, where it is required to create a work area with a higher class of cleanliness. Option of placing a weighing booth separate from a clean room.

Weighing booths prevents penetration of contaminated air and microorganisms from entering the work area, isolate and remove pathogenic biological agents and prevent contamination of the environment.

Characteristics 1 The Negative pressure weighing room design, material, manufacture, assembly, debugging and so on met the new GMP pharmaceutical production specification requirements 2 Whole body is made of stainless steel after forming, bending, welding, assembling, high flatness, convenient and clean. The electric cabinet can be selected in two ways: internal and external 3 Negative pressure weighing chamber adopts modular design, convenient in and out of the field assembly and disassembly between weighing. 4 The overall stainless steel structure is durable and easy to clean. 5. It is a device to avoid the leakage of dust and protect the product during the weighing of raw and auxiliary materials. Benefits of weighting booth Weighing booths offer numerous benefits in various industries, particularly in manufacturing and quality control processes. These specialized booths provide a controlled environment for accurately measuring the weight of products or materials with precision and consistency. By isolating the weighing process within a designated area, weighing booths help eliminate external factors such as air currents or vibrations that could affect measurement accuracy. Additionally, weighing booths are equipped with advanced technology such as anti-static solutions to prevent electrostatic interference, ensuring reliable results every time. Furthermore, these clean room booths can be tailored to meet specific requirements, including size constraints and containment needs for hazardous substances. Overall, investing in a weighing booth can significantly improve efficiency and reliability in weight measurement tasks while maintaining high standards of quality control. HOW DOES WEIGHING BOOTH WORK After a three-stage cleaning 70% of clean air through air grills enters the working area with a descending unidirectional flow and then, after circulating the product, returns to the lower non-working zone of the booth into the intake grids of the filter unit, the remaining 30% of clean air is sent to the room. Remote air is compensated by the air of the room, coming through the leakages under the curtain into the lower non-working area of the sampling booth in pharmaceutical industry and further into the intake grilles of the filter unit. Air flow ensures the rapid removal and utilization of formed aerosols, prevents their accumulation in work area and entry into the original premises, and also excludes formation of explosive mixtures. |

Technical Parameters

| Cleanliness | Class 100/ISO5 |

| Equipment include | Stainless steel 304 wall, PVC curtain door |

| PLC control | |

| 0.3-0.6m/s velocity | |

| External size: 1800*1500*2450mm | |

| Internal size: 1700*1000*2000mm | |

| Filter type | G4 pre filter, F6 bag filter, H14 gel seal hepa filter |

| Application | Pharmaceutical Industry,workshop,food factory,medical,biology laboratory |

| Qualification Documents | CE |

| Our Service | Professional Consultation, User-friendly English Sofaware, 24 hours technical support,Foreign installation and commissioning |

Installation

In order to know your requirement, please fill the following table carefully and supply CAD layout, so that we can provide correct scheme and quotation, thank you!

How to get a quotation >>