Hard Wall Acrylic Board Clean Booth for pharmaceutical/food/medical industry

Service: Video technical support, Online support

Warranty: 1 year

Certification: CE ISO GMP

Usage: Pharmacy/Medical/workshop

Lighting: LED (CE UL)

Clean grade: From Class100-100000

Power Supply:AC 100~240V 1 phase,AC 220~480V 3 phase

Type:Vertical Air Flow,horizontal Air Flow

Limit Discounts

Description

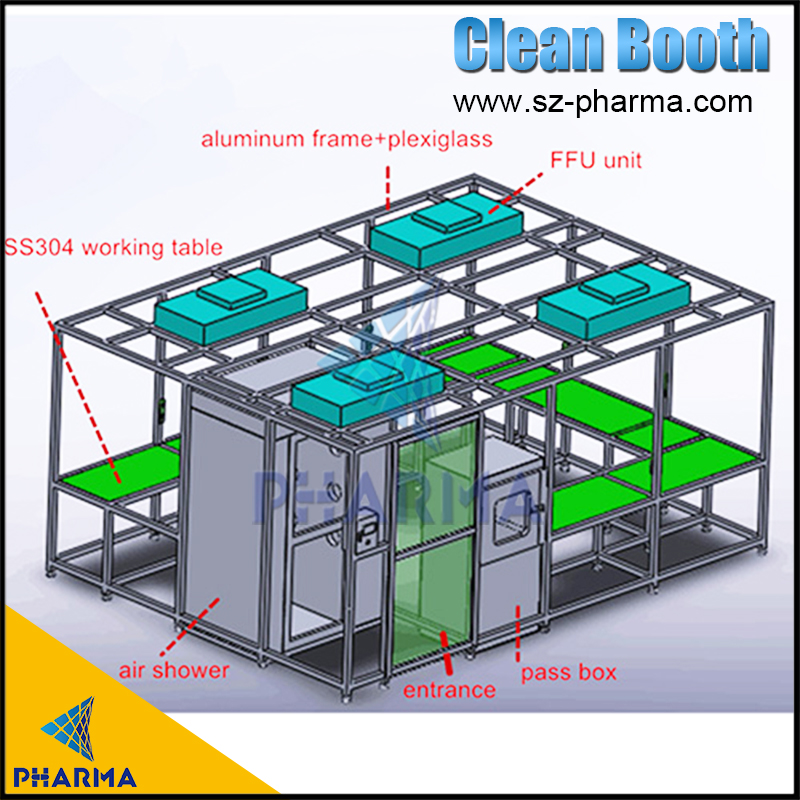

A clean booth is a portable, cost-effective, modular enclosure that creates a localized, high-cleanliness environment using Fan Filter Units (FFUs) and HEPA filters to remove airborne particles, ideal for industries needing dust-free areas for electronics, pharmaceuticals, or testing without a full cleanroom. They offer fast installation, flexibility, and are easily moved, providing a controlled atmosphere for sensitive processes like dispensing, sampling, or assembly, with options for temperature control and different structures (hard/soft wall).

The acrylic hard wall clean booth can effectively isolate pollution sources in the packaging and formulation preparation processes in the pharmaceutical industry. Its high transparency facilitates monitoring of the operation procedures, and its chemical corrosion resistance meets the frequent disinfection requirements. In the food industry, its closed structure ensures the cleanliness of the production packaging area, blocks microorganisms and dust, and its easily cleanable surface design complies with food safety standards, enhancing product quality and production efficiency.

The clean booth produced by Suzhou Pharma Machinery uses high transparency acrylic sheets as the core enclosure material. It not only offers clear visual transparency but also ensures overall stability through sturdy industrial aluminum profiles or stainless steel frames. At the same time, it effectively isolates external pollution sources, maintaining the cleanliness and safety of the internal environment. In terms of cleanliness control, our products achieve this through the integration of efficient filtration systems (such as FFU fan filter units) and sealing designs, ensuring the uniformity of air circulation and the stability of cleanliness levels. This effectively meets the stringent requirements of various industries for particles and microorganisms.

Clean booth class 10000 installation is convenient and easy to operate. We can provide complete construction drawings, installation process drawings, online installation, commissioning and guidance, and multi-step detailed installation videos. We don’t need professional people to complete the engineering work smoothly under our guidance.

Common Uses

Pharmaceuticals & Biotech: Sterile manufacturing, compounding, dispensing.

Electronics: Preventing defects in micro-assembly.

Testing & Research: Accurate measurement in labs.

Food Processing & Cosmetics: Quality control.

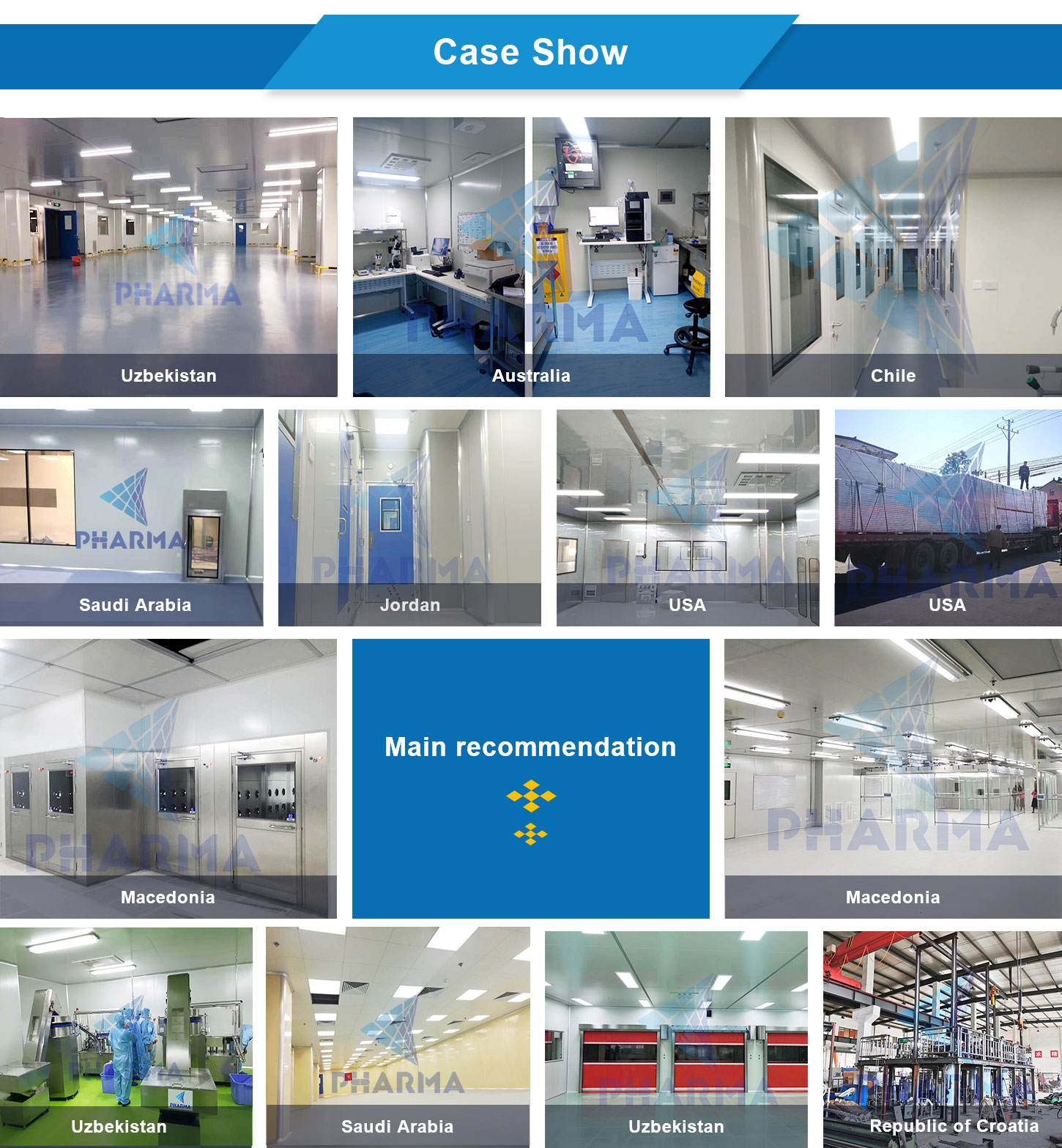

Many old users continue to order different products from our company every year. The products are guaranteed, the company is credible, and the workers have professional construction standards. Our company has completed more than 500 clean room projects all over the world.

We welcome your visit 24 hours a day to order our company's clean room engineering and all products.

| Structures: 1. Clean area: hard wall and ceiling acrylic. 2. Ceiling and accessories: aluminum construction. 3. 900*1200mm single swing door. 4. Equipment: FFU frame, LED light, control box. Advantages: (1) Assembly structure designed, east installation and easily moved. (2) Directional wheels can be installaed, suitable for small building and high cleanliness area; (3) Modular design: clean booth can be as small as several square meters and can be as lager as hundreds of square meter. (4) It has large useful and effective area; while compared with traditional clean room, it has such features like low investment, high return and stable |

Technical Parameters

| Parameter | Hard Wall Clean Booth |

| Cleanliness | ISO 5 to ISO 9 |

| Project include | 1. Structure: Wall Panel, Ceiling Panel, Aluminum Construction Doors, LED light, FFU Frame, Control box |

| External Dimension | L5*W5*H2.5m |

| Application | Pharmaceutical Industry, workshop, food factory, medical, biology laboratory |

| Qualification Documents | ISO,CE |

| Air filter | 99.99% @0.3μm |

| FFU | 2*4ft/4*4ft 9pcs |

| Power | 110V/60hz/av/dc, 220V/60HZ/AV/DC |

Installation

In order to know your requirement, please fill the following table carefully and supply CAD layout, so that we can provide correct scheme and quotation, thank you!

How to get a quotation >>