Focuses On Professional Cleanroom Project And Pharmaceutical Cleanroom Equipment.

Sterility Test Isolator for Chemical Clean Room

After Warranty Service: Video technical support, Online support

Certification: CE ISO GMP

Name: VHP Isolator

Application: Cleanroom, lab, dust-free room

Compressed Air Volume: 0.5MPa

Power V/Kw: AC220 /3.5

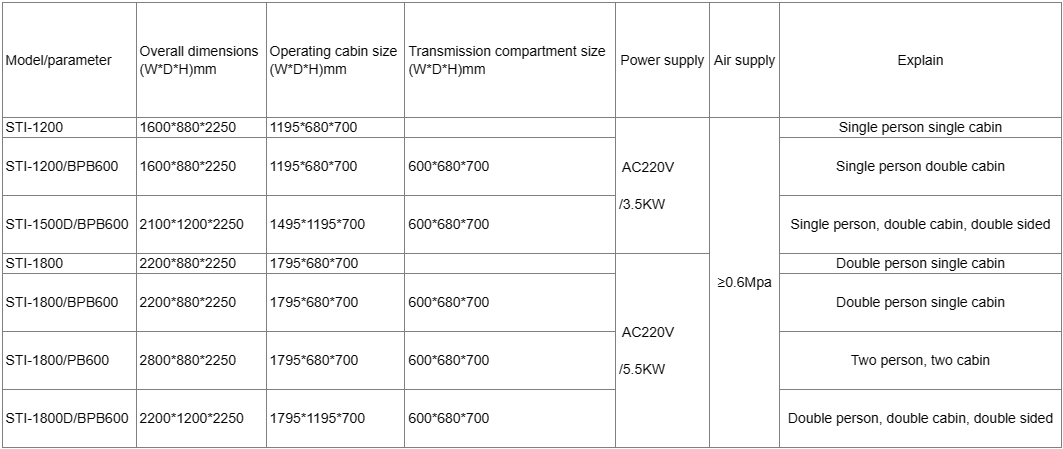

Transfer Cabin Size (W*D*H)mm: 600*680*700

Operating Cabin Size(W*D*H)mm: 1195*680*700

Outer Dimension(W*D*H)mm: 1600*880*2250

Cabin Material: External Full 304 Stainless Steel

Limit Discounts

Description

A VHP aseptic isolator is a device that uses Vaporized Hydrogen Peroxide (VHP) technology to achieve internal space sterilization. This type of isolator is widely used in industries such as pharmaceutical, biotechnology and food processing to ensure a highly clean and sterile operating environment, thereby avoiding microbial contamination of the product.

The VHP disinfection technology works by converting liquid hydrogen peroxide into a gaseous state and dispersing it evenly inside the isolator via a specific distribution system. Because of its strong oxidation ability, gaseous hydrogen peroxide can effectively kill bacteria, viruses, fungi and spores. In addition, hydrogen peroxide decomposition products are water and oxygen, leaving no harmful residues, so it is ideal for applications requiring high cleanliness.

| Efficient bactericidal ability: VHP can effectively kill a variety of microorganisms including bacteria, viruses, fungi and spores.

Rapid action time: Compared with traditional wet heat sterilization methods, VHP disinfection is usually completed in a shorter time, which can greatly reduce the time of production disruption and improve work efficiency.

No residue and environmental protection: Hydrogen peroxide decomposes into water and oxygen after use, leaving no harmful substances behind, so it is environmentally friendly and reduces the risk of secondary pollution. Low corrosion: Improved VHP technology reduces the corrosion of materials, which allows it to be applied to more types of surfaces and materials without damaging equipment or instruments. Drying process: VHP disinfection is a drying process that is a great advantage for sensitive electronic devices or materials that cannot withstand wet environments. Wide applicability: In addition to the pharmaceutical industry, VHP technology is also suitable for healthcare, laboratory research, food processing and many other fields. |

| Material | External all 304 stainless steel, internal chamber 316L stainless steel |

| Cleanliness level | Class A |

| Wind speed | 0.45m/s ± 20% |

| Leakage rate | ≤ 0.5% VOL/h (below 100pa) |

| Exhaust volume | ≥ 300m ³/ H |

| Pressure control range | 100pa~+100pa |

| Sterilization efficiency | 6lg |

| VHP residual removal efficiency | ≤ 1PPM |

| Control method | Manual or automatic |

| Noise | ≤ 68dB (A) |

| illumination | ≥ 350LUX |

Installation