Focuses On Professional Cleanroom Project And Pharmaceutical Cleanroom Equipment.

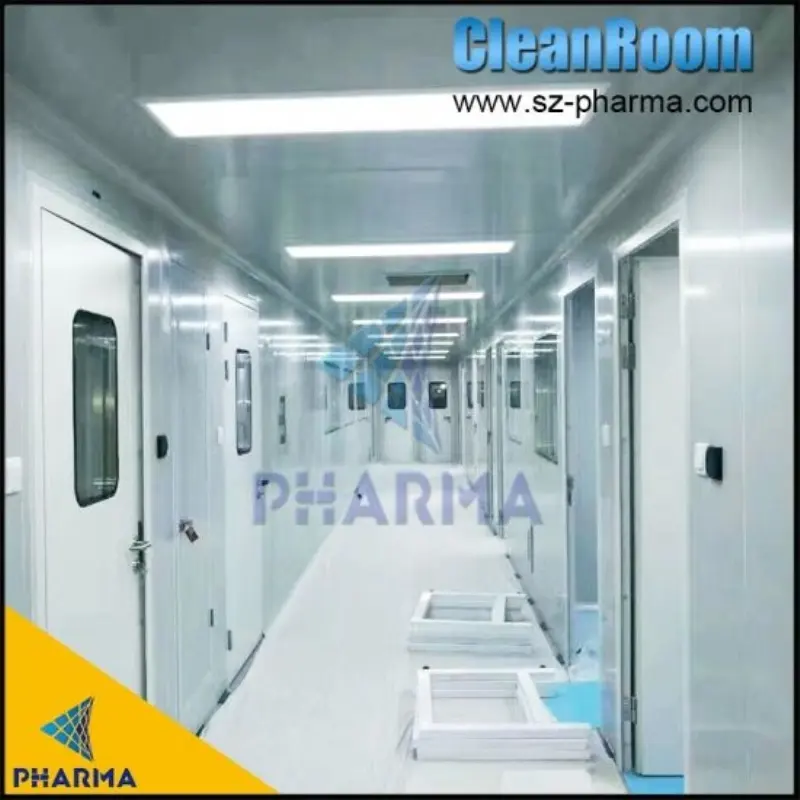

Professional Customized Industrial Medical Clean Room

After Warranty Service:Video technical support, Online support, Field maintenance and repair service

Warranty:1 year

Certification:CE ISO GMP

Usage:Laboratories

Floor:PVC

Lighting:LED

Clean grade:From Class100-10000

Name:Cleanroom Project

Power Supply:200~240V

Type:Vertical Flow

Limit Discounts

Description

What is a clean room:

The clean room is a very broad application industry, and the air cleanliness, temperature, humidity, pressure, noise and other parameters are controlled according to the needs of the clean room use. At present, it has applications in many industries, such as electronic information, semiconductors, precision manufacturing, medicine and health, aerospace and automotive spraying.

Clean working principle:

Airflow→primary purification→humidification section→heating section→surface cooling section→medium-efficiency purification→fan air supply→pipeline→high-efficiency purification air outlet→into the room→take away dust and bacteria and other particles→return air shutters→primary purification

Standard incoming and outgoing procedures for goods and personnel in GMP clean room. 1 Changing room:change shoes,clothes,wash hand disinfection 2 Air shower:it can use air clean class 100 wind to clean the dust on surface of goods and personnel. 3 Clean area:Place GMP standard machines, production equipment or laboratory equipment, etc 4 In pharmaceutical production, raw material storage room and finished product packaging room are usually required |

If you want clean room for your Pharmaceutical or Related factory/Hospital/Electric product factory/Plant growing green house...etc.

You need provide these basic information to us:

1.What size clean room do you want to build?Do you have layout drawing?

2.What temperature and humidity do you want for your clean room?Whats local temperature and humidity?

3.What product or work will be do in the clean room?

4.Do you have factory now or just ground?

5.Whether have other special requirement?

Technical Parameters

| Name | Pharmaceutical Clean Room |

| Cleanliness | Class 100 to Class 100000, ISO 5 to ISO 9, Class A to Class D |

| Temperature&Humidity | According to clean room application |

| Fliter | Hepa Box/FFU |

| Application | Pharmaceutical,precision machinery industry, electronics industry (semiconductor, integrated circuit, etc.),food,cosmetic,planting |

| Structure | Wall Panel, Ceiling Panel, Windows, Doors, Various Fittings, Flooring |

| Electric | Lighting, Switch, Cables, Wires, Power Distribution Cabinet, etc |

| Automatic Control System | PLC Controller, Sensors for Humidity and Temperature, Control Panel |

| Brand | Suzhou Pharma Machinery |

| Our Service | Free design, Professional consultation, 24 hours technical support,Foreign installation and commissioning |

Installation

In order to know your requirement, please fill the following table carefully and supply CAD layout, so that we can provide correct scheme and quotation, thank you!

How to get a quotation >>