Portable Vertical Horizontal Laminar Flow Clean Bench Benchtop Laminar Flow Food

After Warranty Service: Video technical support

Certification: CE

Name: Laminar flow hood

Power supply: 220V/50Hz or Customized

Size: Customize

Used: Clean room industry

Material: stainless steel 304/316

Clean grade: ISO5

Limit Discounts

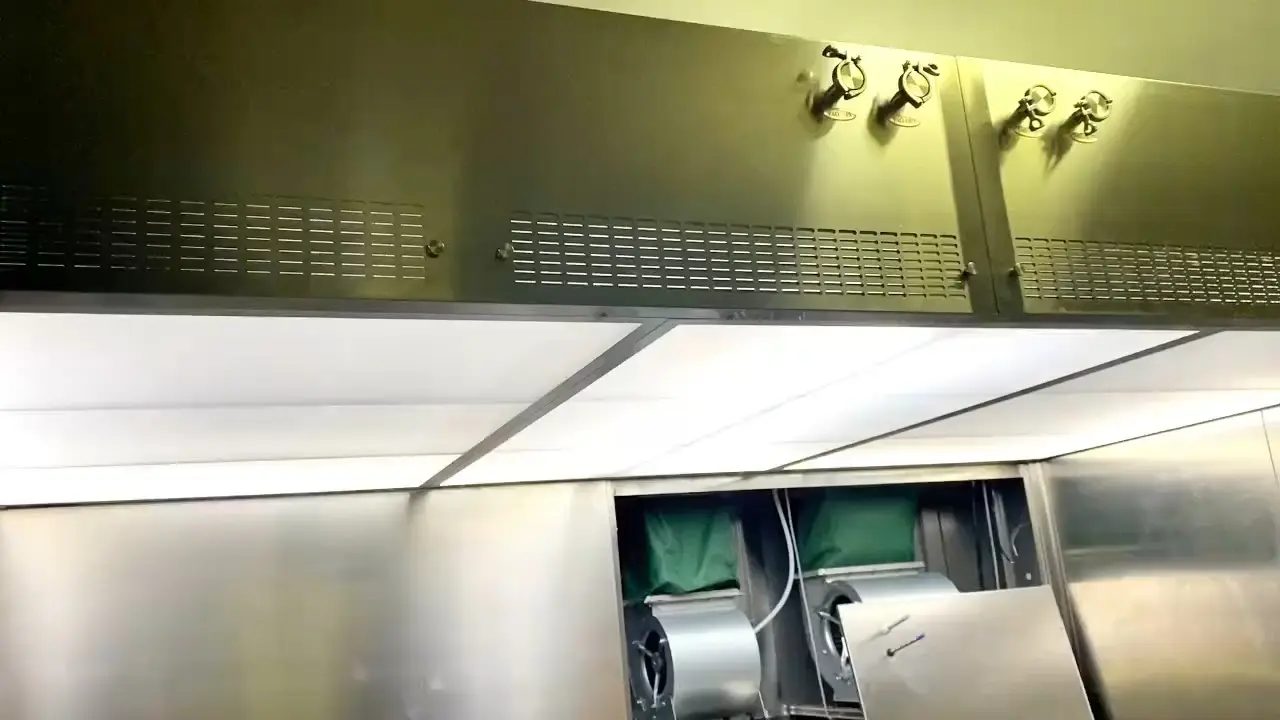

The laminar flow hood draws air from the clean room and, through a fan installed in the top pressurized compartment, filters the air through the HEPA and vertically through the operating area, providing unidirectional air flow to the critical area. Exhaust gases are discharged from below and returned to the cleanroom area. This design ensures that the air in the work area is always clean. It is mainly used to provide a local high clean working environment. Laminar flow hood is mainly composed of box, fan, high efficiency air filter, damping layer, lamps and so on.

Ceiling Laminar Airflow hood is a containment equipment utilizing a unidirectional (laminar) downflow supply of air to pressurize and purge the working environment from potential contaminants; providing enhanced aseptic work zones to maintain process integrity and product protection.

The air is forced evenly through HEPA filters, resulting in a laminar stream of clean air that is projected vertically over the internal work zone.The downflow supply of air from the ceiling laminar airflow unit flushes and dilutes all airborne contaminants to providing a particulate-free work environment.

Operating at low noise level allowing efficient and comfortable working environment conditions.Equips with differential pressure gauge for filter pressure examination.Provision of emergency stop button.UV lamp for sterilization.LCD display of real-time pressure, temperature and humidity.

| Applications:1. Pharmaceutical Production: Suitable for tablet coating, sterile drug formulation, and packaging. 2. Biotechnology Research: Provides a contaminant-free environment for sensitive processes, including cell culture and DNA/RNA manipulation. 3. Electronics Manufacturing: Ideal for assembly and inspection of components, including semiconductors and microchips. 4. Aseptic Processing: Ensures sterile conditions for the preparation of medical devices, injectable drugs, and other critical products. 5. Food and Beverage Processing: Protects food and beverage ingredients during packaging and filling processes, ensuring safety and compliance with hygienic standards. 6. Laboratory Applications: Suitable for microbiology, chemical analysis, and quality control testing where contamination-free environments are essential. |

Features:

- It adopts modular design which is convenient for transportation and installation, and can meet different site layout requirements.

- Adopt special fan for laminar flow hood, high stability and low noise.

- The double layer structure reduces the vibration noise of the fan, and the appearances simple and beautiful.

- Equipped with PAO testing port it is convenient to verify the installation reliability after replacing the filter. At the same time, a differential pressure gauge is configured to monitor the use of high efficiency filters in real time.

- According to the different installation requirements of the site, the side indoor return air the top indoor return air the side take over return at the top take over return air and other structures can be selected.

- Different installation methods such as suspension mounting and bracket mounting can be used.

- According to different installation heights, the C control panel and the laminar flow hood can be installed Integrated,or an independent control box can be installed to a suitable height on the wall.

- High efficiency air purification: laminar flow hood through the high efficiency air filter (HEPA), the air is filtered at a certain speed to form a flow layer, so that the clean air is vertical one-way flow, to ensure that the working area to meet the process requirements of high cleanliness. Its cleanliness can reach ISO 5 (Class 100), that is, dust ≥0.5μm particle size in the work area ≤3.5 pieces/liter (FS209E100 class).

- Flexible structure: The laminar flow cover has the structural characteristics of independence, which can be adjusted at any time to make up for the lack of mobility of the clean room. It can be used alone or combined into a banded clean area to meet the needs of different work areas.

- Various materials: the shell structure of the laminar flow cover can be selected from stainless steel, aluminum plate and cold-rolled steel plate electrostatic spraying material, which has the advantages of light weight, corrosion resistance, rust prevention, beautiful and generous.

| Model | PH-W series |

| Internal Size (W*D*H) | 1600*3000*2600 12000*3000*2600 I 2500*3000*2600 |

| External Size (W*D*H) | 1500*2400*2000 1900*2400*2000 2500*2400*2000 |

| Class/Air Flow | ISO5 0.45±20%m/s |

| Pre-filter | G4 (90%@5um) |

| Med-filter | F8 (85%~95%@1~5um) |

| HEPA filter | H14(99.995-99.999%@0.3) |

| Power Supply | 380V/30/50Hz(Advice if different) |

| Control Mode | VFD Control/Simens PLC Control |

| Rated Power | 3kW 4kW 5kW |

| Total/Exhaust Volume | 8000/800(m3/h) 110000/1000(m3/h) | 13000/1300 |

| UV Light | Optional |

| Light Intensity | 2300Lx |

| Noise | less than 70dB (A) |

| Different Pressure Gauge(3 nos.) | 0-60Pa/0-250Pa/0-500Pa |

| Socket | P66/Qty.4 |

| MOC | SUS304/1.2mm |