Focuses On Professional Cleanroom Project And Pharmaceutical Cleanroom Equipment.

Pharmaceutical Modular Clean Room Turnkey Project

Service:Video technical support, Online support, Field maintenance ,repair service

Warranty:1 year

Certification:CE ISO GMP

Usage:Hospital/Pharmacy/Medical/workshop

Floor:clean room PVC 2mm Homogeneous floor

Lighting:LED (CE UL)

Clean grade:From Class100-100000

Name:modular clean room

Power Supply:AC 100~240V 1 phase,AC 220~480V 3 phase

Type:Vertical Air Flow,horizontal Air Flow

Description

A Pharmaceutical Modular Clean Room Turnkey Project involves pharma cleanroom turnkey contractors handling the entire process of creating a GMP-compliant, prefabricated cleanroom—from design, engineering, & construction with customizable panels, HVAC, & utilities, to final installation, validation, and commissioning, offering a streamlined, fast, and flexible solution for pharma manufacturing that meets strict quality standards.

Use: 1.Control the dust particles, suspended particles and microorganisms in the air to ensure the cleanliness of the production or operation area. 2.Provide a stable temperature, humidity and clean environment. 3.Ensure that the production environment meets specific cleanliness requirements.

Modular Clean Room normally size is 3000mm*4000mm*2500mm. Two People can Installation complete it in 2 hours. Quick and easy to install, it also can by our engineer and local engineer togeter. Cleanroom can have many functions because of their different designs. For example, home, office, hotel, restaurant, bathroom, toilet, clean room, laboratories, workshops, schools, hospitals, etc. We have a lot of customers in Europe, the United States. Turnkey cleanroom's very popular and hot sale now.

Applications: Pharmaceutical factory, medicine factory, food factory, hemp factory, lab, vaccine factory, infusion factory, bottle plastic factory and so on.

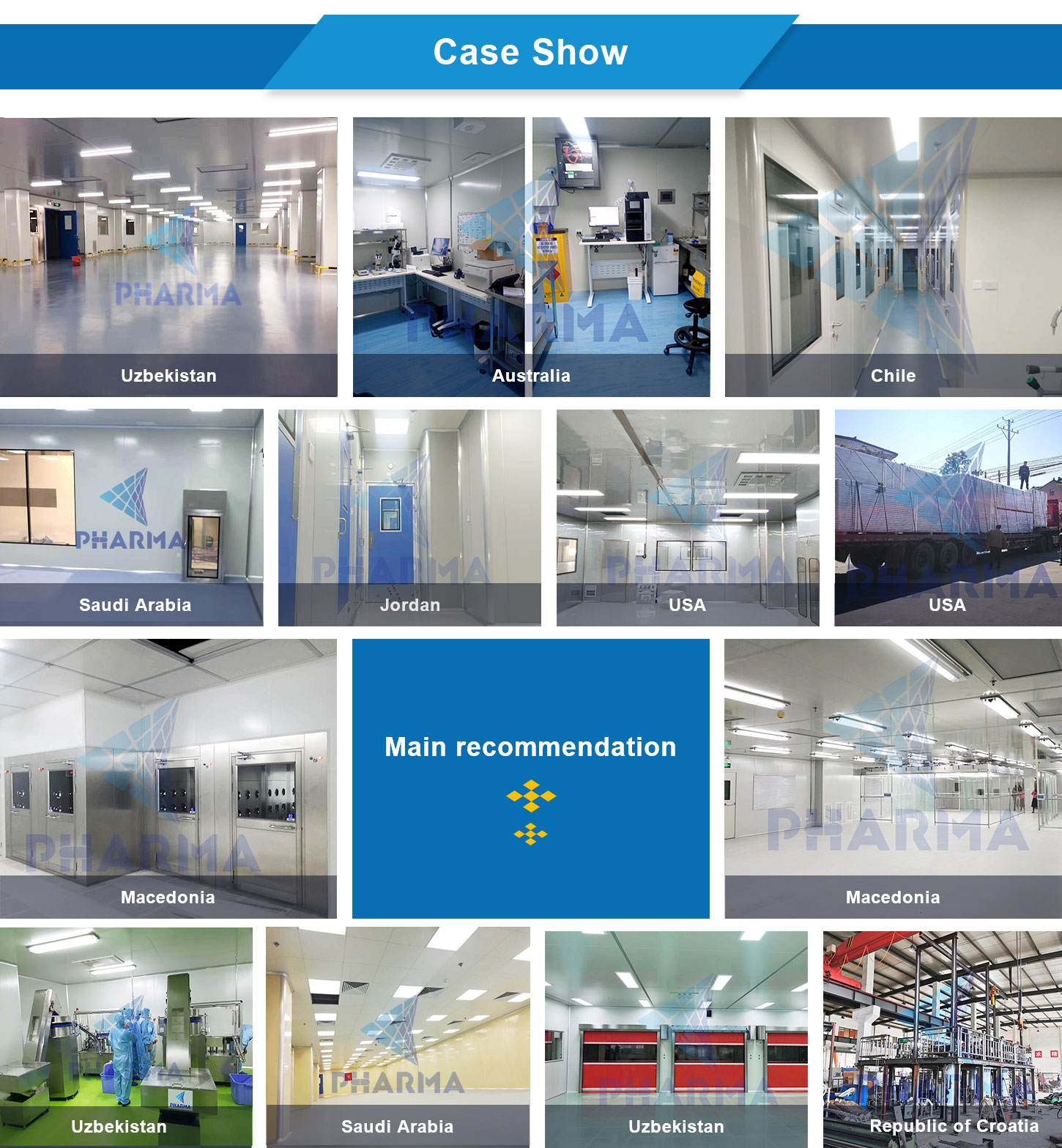

With more than 17 years of experience, Suzhou Pharma has done more than 500 cleanroom projects. Suzhou Pharma is not only proficient in one-stop pharmaceutical cleanrooms solutions but also excels in HVAC systems.

| Advantage of turnkey cleanroom 1.Easy to disassemble and install according to drawings, faster deployment than traditional construction. 2.Customer can customized size and DIY the cleanroom area according to their space requirements, easily reconfigured or expanded as needs change. 3.The room area can be enlarged at any time, only increase a few GMP panels or doors. 4.Clean room is movable, often cheaper to modify than building new, low cost and low time-consuming. 5.Reduced Risk: Single point of responsibility minimizes conflicts and errors. |

Technical Parameters

| Cleanliness | Class 100 to Class 100000, ISO 5 to ISO 8, Class B to Class D |

| Project include | 1. Structure: Wall Panel, Ceiling Panel, Windows, Doors, Various Fittings, Flooring |

| 2.Electric: Lighting, Switch, Cables, Wires, Power Distribution Cabinet, etc | |

| 3.HVAC: AHU, Ducting, Piping, Chiller, dehumidifier, etc. | |

| 4.Auto-control: PLC Controller, Sensors for Humidity and Temperature, Control Panel | |

| 5. Process Piping System: Gas, Water Pipeline | |

| Temperature&Humidity | As clients request |

| Application | Pharmaceutical Industry,workshop,food factory,medical,biology laboratory |

| Qualification Documents | ISO,CE |

| Our Service | Professional Consultation, User-friendly English Sofaware, 24 hours technical support,Foreign installation and commissioning |

Installation

In order to know your requirement, please fill the following table carefully and supply CAD layout, so that we can provide correct scheme and quotation, thank you!

How to get a quotation >>