Focuses On Professional Cleanroom Project And Pharmaceutical Cleanroom Equipment.

PHARMA stable filter fan unit manufacturer for cosmetic factory

1. PHARMA hepa filtration unit is produced under up-to-date technology. From the textile fiber screening to the quality inspection stage, nanotechnology, supercritical fluid extraction technology, and plasma technology are applied.

2. This product helps save production costs. There are potential savings to be gained from reduced medical claims of employees, greater production output.

3. The product is valued for their flawless features and superior long-time performance.

After Warranty Service:Video technical support, Online support

Warranty:1 year

Certificate:ISO9001

Filtration Efficiency:HEPA H14 99.997% @ 0.3 micron

Size:Customsize

air speed:0.3-0.6m/s

Type:ceiling filter box

Power supply:none

Limit Discounts

Description

The HEPA box is an ideal terminal filter device for class100/1000/10000 and 100000 grade purifying air conditioning system, which can be widely used in the fields of medicine, sanitation, electronics, pharmaceutical, chemical industry cleanrooms.

The HEPA box includes a static pressure box, a diversion plate, a high-efficiency filter, and an air flow regulating valve. The interface with the air duct can be top-connected or side-connected.

Characteristics 1.Test ports for pressure drop, test groove and aerosol injection 2.Available air flow adjustment damper fitted to the spigot 3.Available in various construction and dimensions 4.Simplified maintenance and disinfection 5.Easily removable air outlets 6.Available powder coated or stainless steel 7.Central fixing for diffuser 8.Duct Connection Type: Top, side, Z 9.Powder coated or SS 304 10.Special production with low construction height |

Technical Parameters

| Housing Material | Powder Coated Steel Plate or SS304 | ||

| Filter Type | Aluminum Pleat, Mini-Pleat or Gel Type | ||

| Filtration Efficiency | EAE12)>99 5%, HEPA(H14)299 95%9 or ULPAU7299 9999 @ 01.0.3um | ||

| Diffuser Type | Perforated or Swirl | ||

| Spigot Side | Top, side orZ | ||

| Box Dimension | 455x455x250 | 595x595x250 | 695x695x250 |

| Filter Size | 410x410x93 | 550x550x93 | 650x650x93 |

| Air Duct Connection Size | 200x200 | 320x200 | 320x250 |

| Cutout Size | 465x465 | 605x605 | 705x705 |

| Air Volume | 500m³/h | 1000m³/h | 1500m³/h |

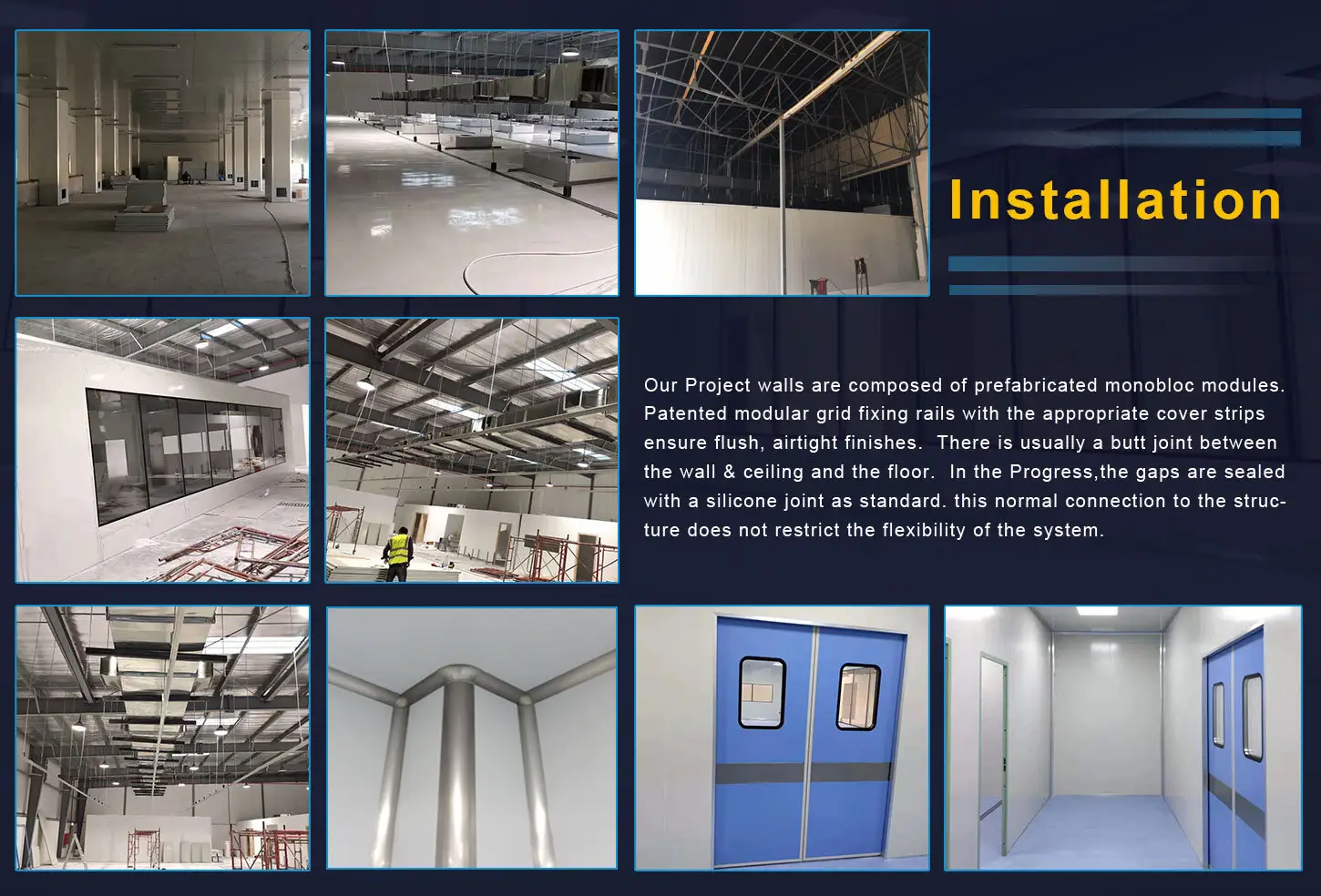

Installation

Company Features

1. SUZHOU PHARMA MACHINERY CO.,LTD. excels in manufacturing a broad range of products such as hepa filtration unit . We are proud to boast rich production experience.

2. Our company has a team of team experts. They are proficient in all the complexities of product production and can assist the manufacturing process to achieve the company's perfect production goals.

3. In every production process of hepa fan filter unit , we always maintain a professional attitude. Get more info!