Focuses On Professional Cleanroom Project And Pharmaceutical Cleanroom Equipment.

PHARMA ISO5-ISO8 Cleanroom class 100000 clean room check now for herbal factory

1. PHARMA hvac system clean room is made by using good quality materials under the supervision of the professionals.

2. SUZHOU PHARMA MACHINERY CO.,LTD. will improve responsiveness to meet the changing needs of different global customers.

3. The product features a clean appearance. It is coated with a special layer to effectively prevent adhesion of dust or oil smoke when being placed.

4. The product has the advantage of stable mechanical properties. Having been treated under extremely cold temperatures, its mechanical components are tensile enough to withstand extreme industrial conditions.

5. This product has the required safety. Different requirements regarding architecture and risk classification of this product have been considered carefully in the manufacture.

After Warranty Service:Video technical support, Online support, Field maintenance and repair service

Warranty:1 year

Certification:CE ISO GMP

Usage:Laboratories

Floor:PVC

Lighting:LED

Clean grade:From Class100-10000

Name:Cleanroom Project

Power Supply:200~240V

Type:Vertical Flow

Limit Discounts

Description

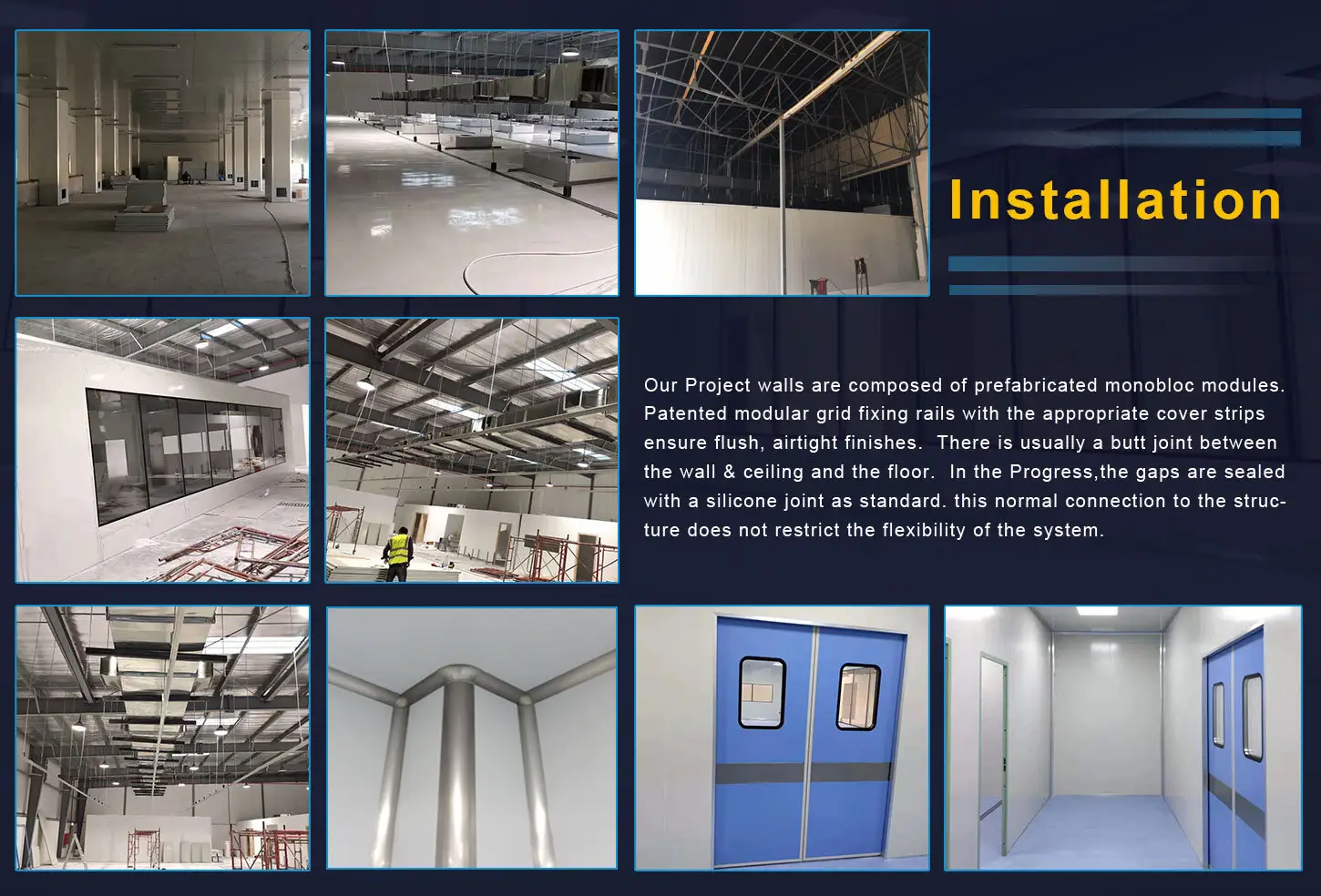

The plane and space design of the clean laboratory will arrange the clean experimental area and personnel purification, equipment and material purification and other auxiliary rooms in different areas. At the same time, the comprehensive coordination effects of various technical facilities, such as experimental operation, process equipment installation and maintenance, air distribution type, pipeline layout and purified air conditioning system, are considered.

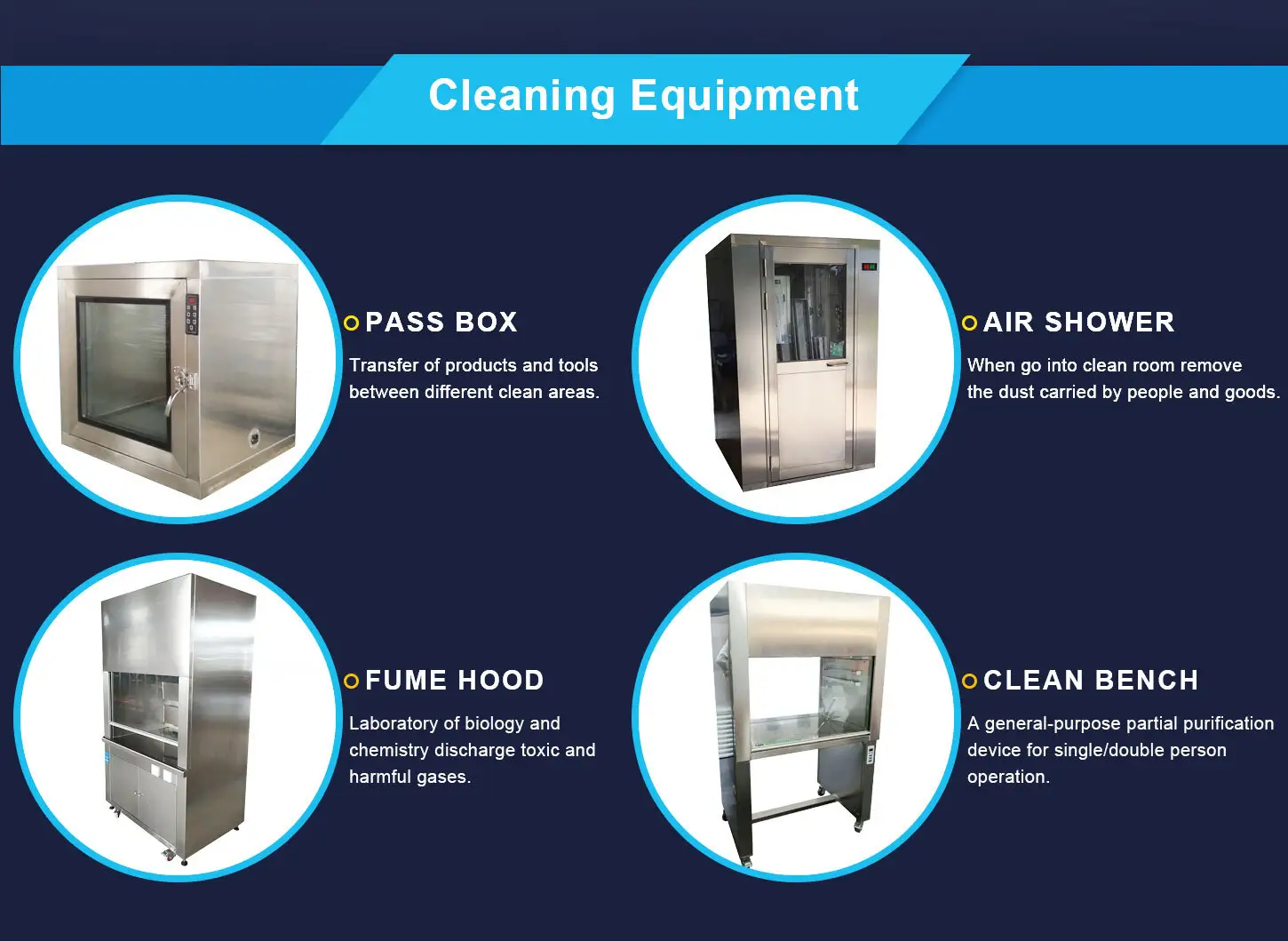

Characteristics 1. Reasonable use of laboratory space layout 2. Meet the laboratory working environment, combined with ergonomics 3. Meet the safety requirements of the test environment If you want clean room for your Pharmaceutical or Related factory/Hospital/ Electric product factory/ |

Technical Parameters

| Application | Solid formulations,tablets, capsules, powder formulations,etc. |

| Wall Material | Sandwich panel |

| Frame Material | 304 Stainless Steel/Aluminum alloy profile |

| Cleanliness | From Class 100 to Class 10,000,0 |

| Power | 110V/60hz/av/dc, 220V/60HZ/AV/DC |

| FFU | 2*4ft/4*4ft |

| HEPA Filter | H14 Hepa filter |

| Lighting | Available in LED and T5 |

| Size | Customize |

Installation

In order to know your requirement, please fill the following table carefully and supply CAD layout, so that we can provide correct scheme and quotation, thank you!

How to get a quotation >>

Company Features

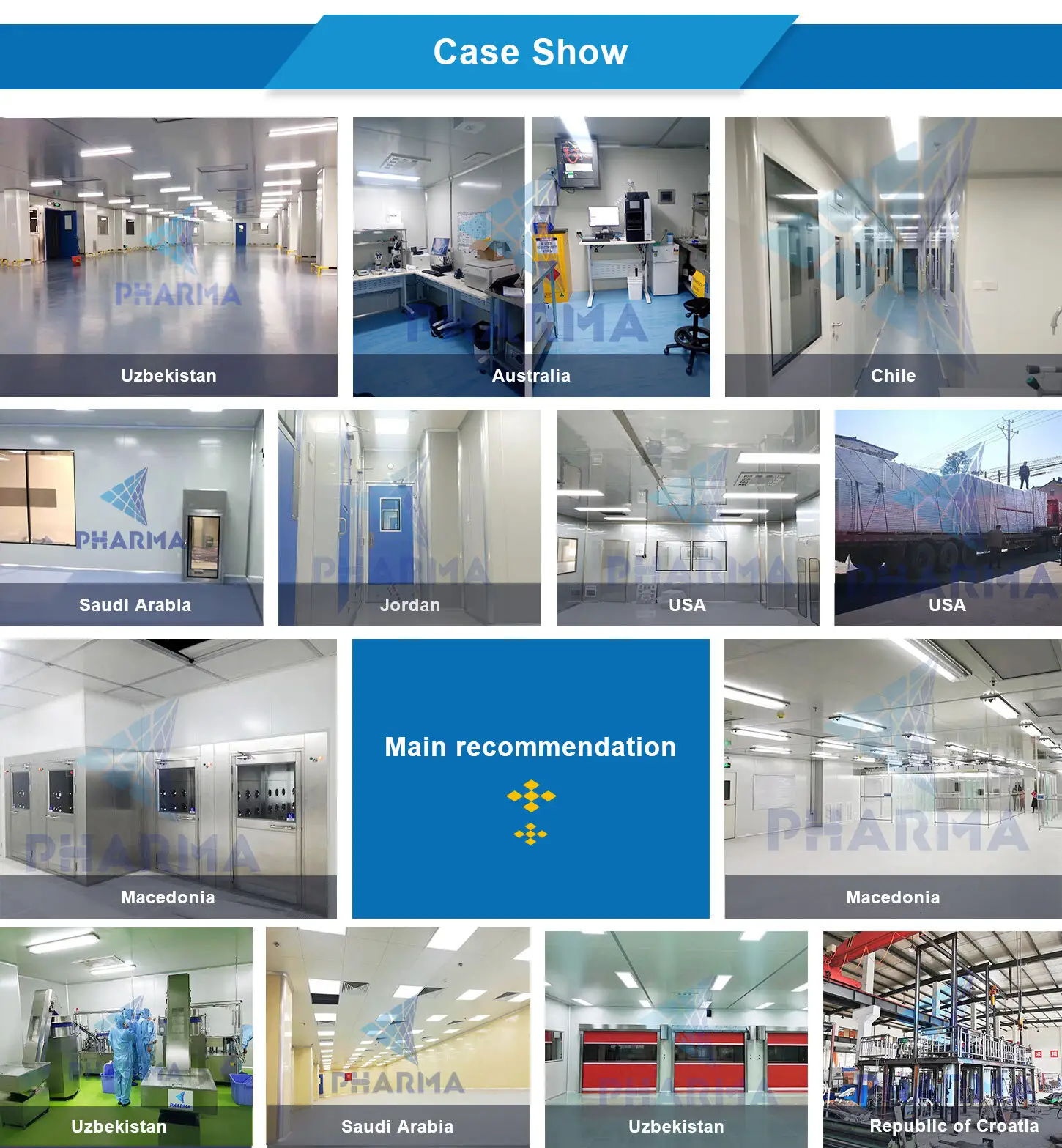

1. Being the front-runner of class 100000 clean room industry, SUZHOU PHARMA MACHINERY CO.,LTD. concentrates on the research, development, and manufacture products with the most competitive prices for many years. Produced by advanced machine and mature technology, clean room gmp is of great performance.

2. SUZHOU PHARMA MACHINERY CO.,LTD. has a dedicated team of supervisors, material managers and operations personnel.

3. SUZHOU PHARMA MACHINERY CO.,LTD. has a park-like production base and a dedicated cleanroom system machining facility. As an important part of PHARMA growth, enterprise culture is a key to make our company more cohesive. Call!