ISO Standard Class 8 Modular Clean Room, Class 100000 Clean Rooms2

Service:Video technical support, Online support, Field maintenance ,repair service

Warranty:1 year

Certification:CE ISO GMP

Usage:Hospital/Pharmacy/Medical/workshop

Floor:clean room PVC 2mm Homogeneous floor

Lighting:LED (CE UL)

Clean grade:From Class100-100000

Name:modular clean room class 8

Power Supply:AC 100~240V 1 phase,AC 220~480V 3 phase

Type:Vertical Air Flow,horizontal Air Flow

Limit Discounts

Description

A cleanroom is a room or contained environment that must maintain a low particle count as outlined in ISO 14644-1. These particles include dust, airborne microbes, aerosol particles, and chemical vapors. In addition to particle counts, cleanrooms also control pressure, temperature, and humidity. A cleanroom also needs high-efficiency particulate air (HEPA) filters to reduce airborne particles.

ISO 14644-1 Cleanrooms are classified from ISO 1 to ISO 9. Each cleanroom class is denoted by a maximum concentration of particles per cubic meter or cubic foot of air. Iso class 8 clean room is the second lowest cleanroom classification.

ISO 8 Cleanroom Standards

The allowed particle counts for an ISO 8 cleanroom depend on the referenced standard and its measurements. According to US Federal Standard 209E, ISO 8 cleanrooms are also known as class 100000 clean room.

.

The modular clean room adopts uniform size plates, and different sizes of plates can also be customized, which can be customized according to the actual size you need. The building materials of the GMP clean room meet the acceptance class 8 cleanroom standards of the GMP clean room.

Clean room class 8 engineering installation is convenient and easy to operate. We can provide complete construction drawings, installation process drawings, online installation, commissioning and guidance, and multi-step detailed installation videos. We don’t need professional people to complete the engineering work smoothly under our guidance. ,Convenient.

The standard product delivery time is 5-8 working days, the customized product delivery time is 10-20 working days, and the customized product delivery time depends on the quantity to estimate the delivery time.

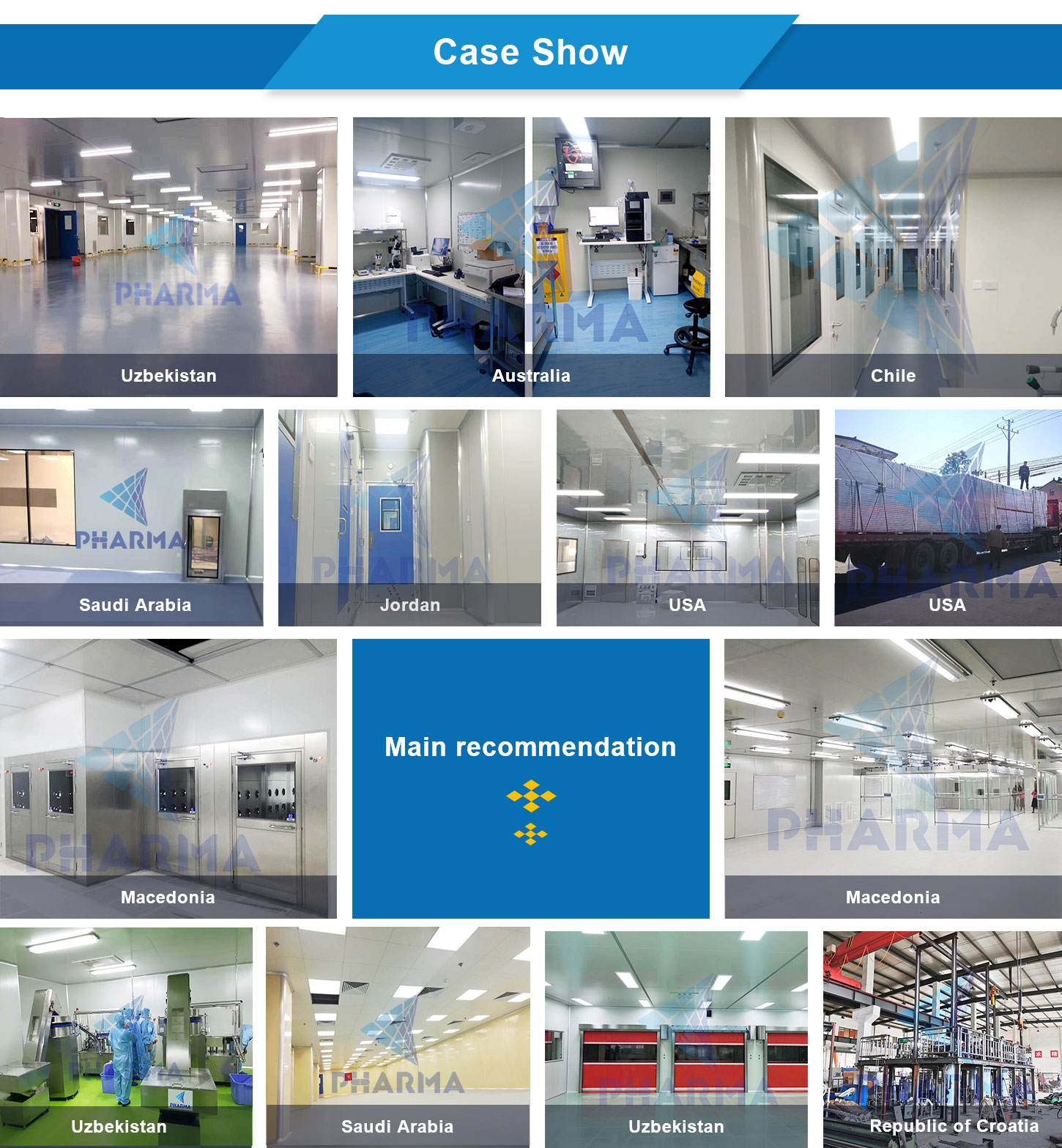

We have a wealth of export experience, with an average of more than 50PCS every year, 40-foot-tall containers are transported overseas. Many countries around the world have cooperated with our company and the feedback is very good.

Many old users continue to order different products from our company every year. The products are guaranteed, the company is credible, and the workers have professional construction iso 8 clean room standards. Our company has completed more than 500 clean room projects all over the world.

We welcome your visit 24 hours a day to order our company's iso class 8 clean room engineering and all products.

| Characteristics of iso class 8 clean room 1 MOQ is 3*2*2m size of the room,ready to shipping in 3 working days. 2 GMP clean room standard design. 3 Export wooden case packing, quick customs clearance. 4 Complete installation drawing, online guide installation and debugging 5. Customers can customize HVAC to realize air supply, return and fresh air duct system Benefits of iso class 8 clean room The benefits of an ISO Class 8 clean room are vast and undeniable. This specialized environment ensures a controlled level of cleanliness that is essential for industries such as pharmaceuticals, electronics manufacturing, and aerospace. By maintaining strict standards for particle counts and air quality, ISO Class 8 clean rooms provide a sterile setting that minimizes the risk of contamination during production processes. This results in higher product yields, improved quality control, and reduced waste. Additionally, the controlled temperature and humidity levels within an ISO Class 8 clean room create optimal conditions for sensitive equipment and materials to operate at peak performance. Overall, investing in an ISO Class 8 clean room can lead to increased efficiency, cost savings, and ultimately greater customer satisfaction. |

Technical Parameters

| Cleanliness | Class 100 clean room to Class 100000, ISO 5 to ISO 8, Class B to Class D |

| Project include | 1. Structure: Wall Panel, Ceiling Panel, Windows, Doors, Various Fittings, Flooring |

| 2.Electric: Lighting, Switch, Cables, Wires, Power Distribution Cabinet, etc | |

| 3.HVAC: AHU, Ducting, Piping, Chiller, dehumidifier, etc. | |

| 4.Auto-control: PLC Controller, Sensors for Humidity and Temperature, Control Panel | |

| 5. Process Piping System: Gas, Water Pipeline | |

| Temperature&Humidity | As clients request |

| Application | Pharmaceutical Industry,workshop,food factory,medical,biology laboratory |

| Qualification Documents | ISO,CE |

| Our Service | Professional Consultation, User-friendly English Sofaware, 24 hours technical support,Foreign installation and commissioning |

Canadian customer installation show

Canadian customer installation show Top view of clean room wall panel installation process

Top view of clean room wall panel installation process  Clean room finished exterior display

Clean room finished exterior display Real effect display of clean room completion

Real effect display of clean room completionInstallation

In order to know your iso class 8 cleanroom requirements, please fill the following table carefully and supply CAD layout, so that we can provide correct scheme and quotation, thank you!

How to get a quotation >>