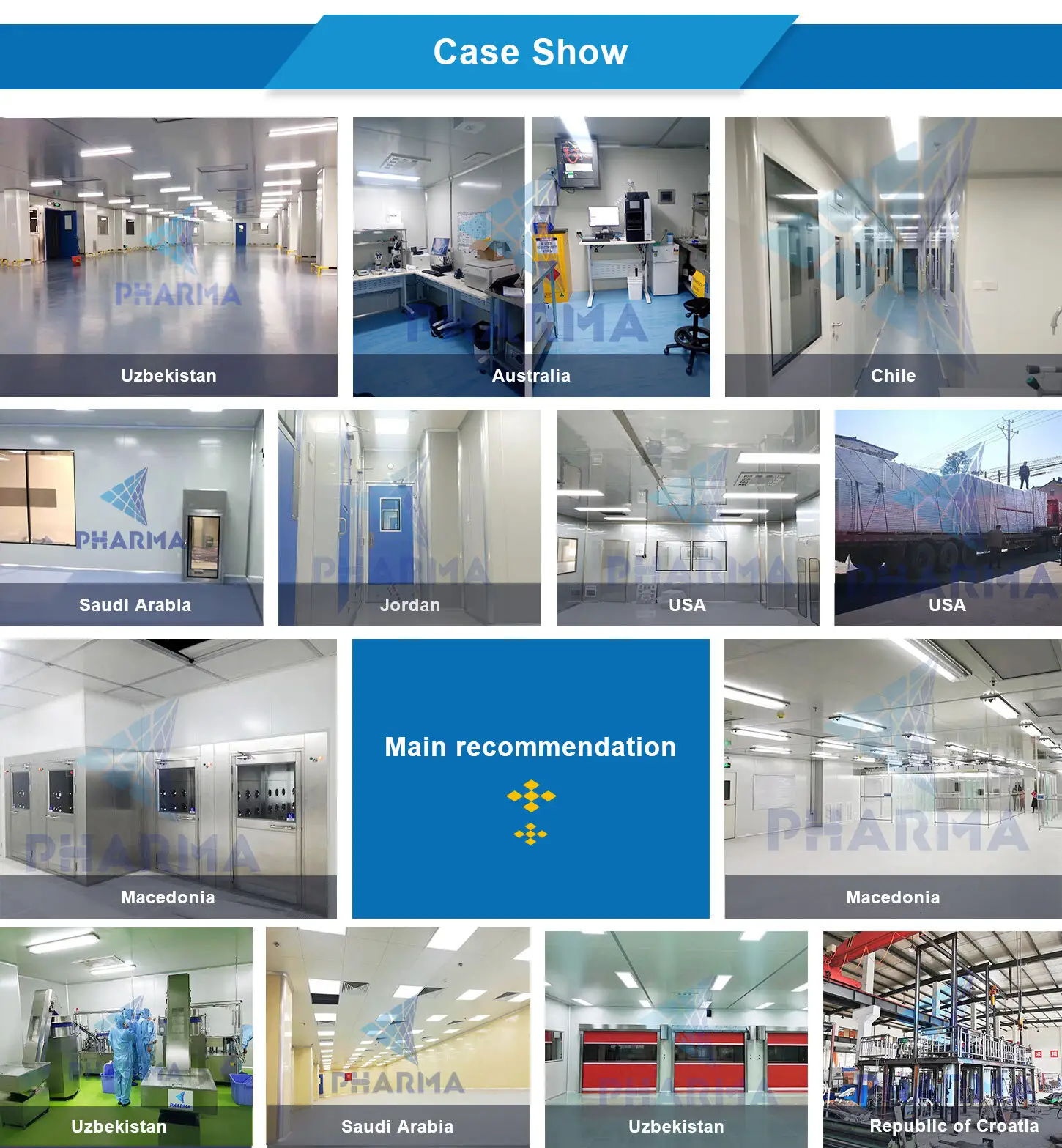

Focuses On Professional Cleanroom Project And Pharmaceutical Cleanroom Equipment.

PHARMA clean room sandwich panel free design for food factory

After Warranty Service: Video technical support, Online support, Field maintenance and repair service

Warranty:1 year

Window frames: aluminum profile

Application: Cleanroom, dust free cleanroom, clean booth, laboratory, medical workshop, food factory

Size:Customized

Surface: electrostatic powder painting processing

Color: color according to customer's requirements;

Form: double open hand plate type

Seal: imported 3M industrial tape sealing, neutral silica gel

Drying: inner adding molecular sieve desiccant

Limit Discounts

Description

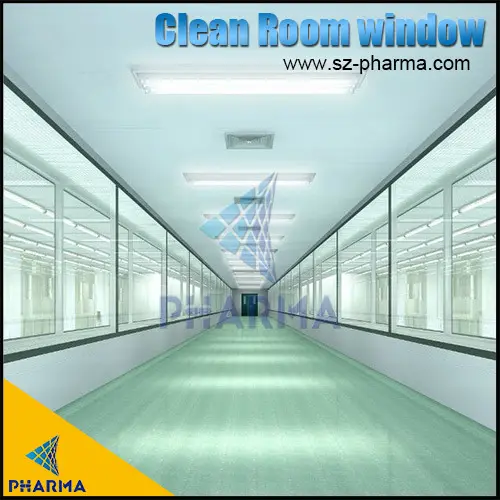

Beautiful appearance, no aluminum alloy frame from the outside, glass and board flush, simple, beautiful, is the manual partition of the board selected products, widely used in purification engineering, food, cosmetics, electronic manufacturing industry.

Good heat preservation, sound insulation, impact resistance, air tightness, water tightness, fire resistance, anti-theft, maintenance free.

Characteristics Glass thickness is 5 mm, mostly from the window to average 1.1 m or 1.2 m,the window height 0.9 meters, width according to plate width, and the general conditions: 0.9 m, 1.2 m, 1.8 m, 2.3 m,specification requires that the fringe of purification workshop use double deck glass,internal with single-layer glass,in the actual construction are all made of single-layer glass more. |

Technical Parameters

| Product category | Clean room window |

| Brand | Pharma |

| The material | Aluminum alloy |

| Function | Sound insulation, dust proof, heat insulation, insect proof. |

| Size | Can be customized |

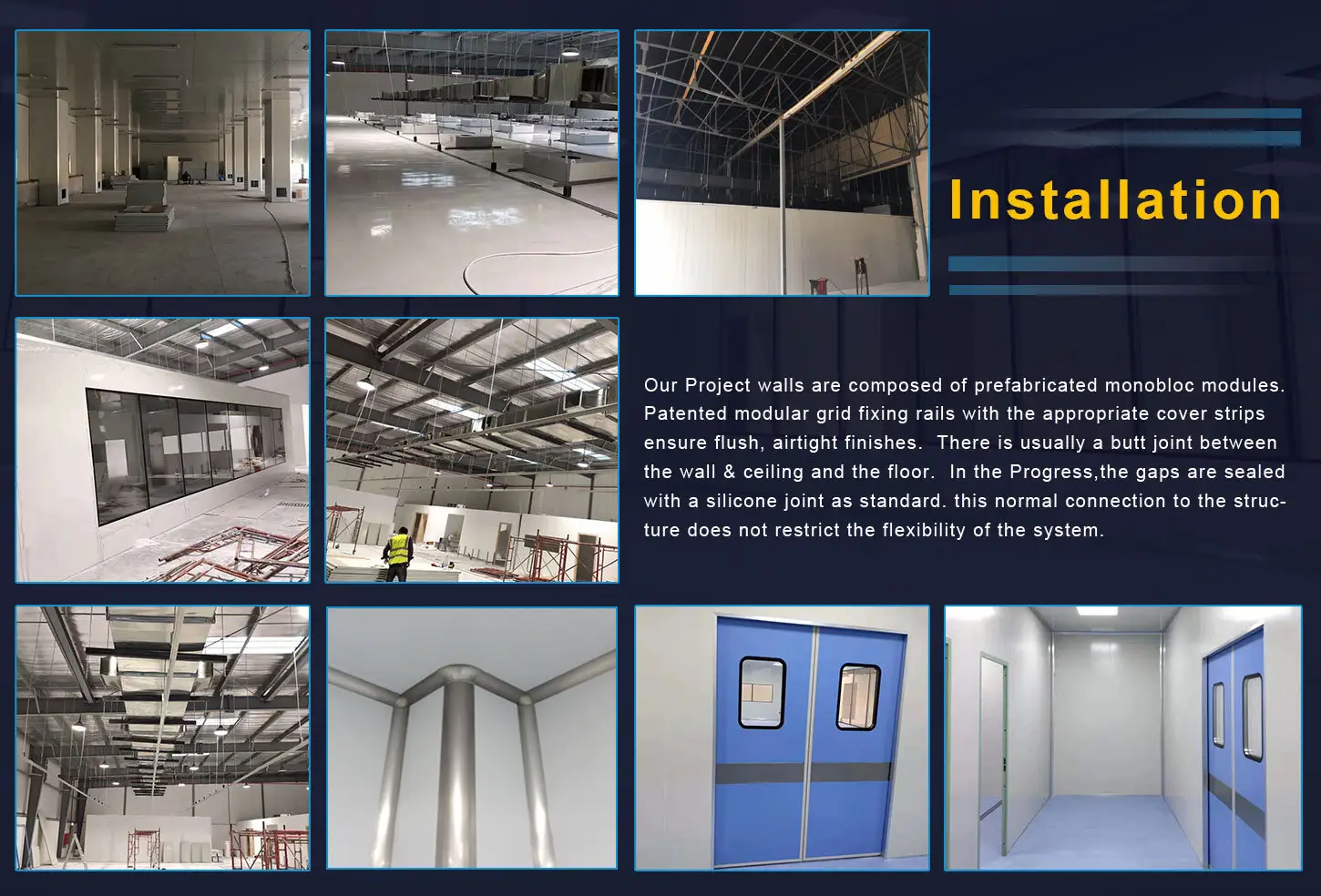

Installation