Best Price GMP Standard Clean Room Sandwich Panel

After Warranty Service: Video technical support, Online support, Field maintenance and repair service

Certification: CE ISO GMP

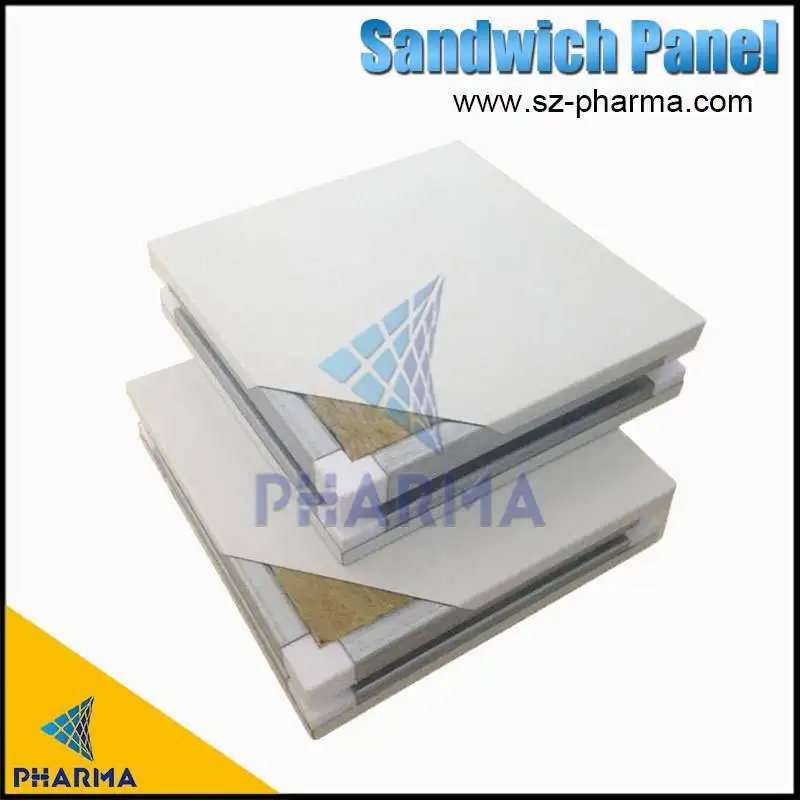

Name: Cleanroom sandwich panel

Core material: Rockwool; PU/EPS sheet

Function: Sound-absorbing; decoration wall

Size: Customized as client request

Application: Pharmaceutical, medical, health, biological clean room/ workshop

Feature: Environmental, fireproof, light weight, metal sheet

Material: Color/ stainless steel

Thickness: 20-500mm

Limit Discounts

Description

What is a clean panel?

Cleanroom panels are being used in cleanrooms to have clean air inside the clean environment while keeping outside dirty.

What type of gmp panel is used in clean rooms?

The surface materials used in gmp clean room panels include melamine, painted aluminum, stainless steel, glass, polycarbonate and vinyl-coated gypsum.

The clean room wall panels include Polyurethane sandwich panels, EPS sandwich panels, Rockwool sandwich panels and honeycomb sandwich panels,etc.

EPS sandwich panel production process adopts the colored steel plate as surface sheet, and the core material is the self-extinguishing closed cell polystyrene foam. It is a kind of high-strength composite building materials, and it was formed in the automated continuous molding machine, by combining the pressed colored steel with the High Strength Adhesives.

Rockwool is made of selected basalt as the main raw material, made by melting at high temperature and man-made inorganic fibers. The utility model has the advantages of light weight, small thermal conductivity, good sound absorption performance, non burning,good chemical stability,etc.

Polyurethane sandwich panel has been used as the main steel building palisade materials, widely used in large industrial plants, cold storage, garage, mobile homes, exhibition hall, gymnasium, shopping centers, airports, power plants, villas, hospitals, office buildings and other fields. Its excellent insulation performance is mainly used in roof and wall of industrial and civil construction.

Characteristics of gmp clean room panels 4. Refractory: The color steel plate treated by special coating is kept for 10-15 years, and then the anti-corrosion coating is sprayed every 10 years. The life of the plate is over 35 years. 5. Beautiful appearance: the clear lines of the profiled steel plate up to dozens of colors, can match the needs of any style of building. 6. Thermal insulation: commonly used insulation materials are: rock wool, fiberglass cotton, polystyrene, polyurethane, etc.,low thermal conductivity, with good thermal insulation effect. How to choose the right cleanroom panels? Cleanroom panel: A clean room’s surface of the wall and ceiling should be smooth, flat, free from dust, and easy to clean using a dust removal procedure. Resistance from Corrosion: Clean rooms usually need to be washed very often. In addition to cleaning with water, disinfectant water or alcohol is also used to disinfect the rooms. The liquids contain several harsh chemicals, which might discolour and fall off certain materials on the surfaces so; we need the cleanroom accessories to be corrosion resistive. Weather Proof: Biological clean rooms like the operating rooms that are generally equipped with O₃ generators which are used for sterilization. This can accelerate the oxidation or corrosion of the objects such as metals in the environment. This will further lead to fading and discoloration of the general coating surface because of oxidation. Therefore, these kinds of cleanrooms require that their decorative accessories should have good resistance for oxidation and will not produce rust. Construction of the room: The cleanroom structure must be made using sealing measures that are reliable and leave no construction gaps in between clean room doors and windows, ceilings, walls, floor surfaces. Colour of cleanrooms: The colour of the clean rooms must be light and gentle, giving workers a comfortable environment to work in. Always go for soothing colours that are not too vibrant for a workspace. You don’t want the technicians getting distracted by the interiors in such a focused environment. |

Technical Parameters

| Product name | Clean room sandwich panel |

| Material of interlayer | PU, EPS, rock wool, glass cotton, paper honeycomb, aluminum plate, glass magnesium sheet, paper honeycomb |

| Thickness of interlayer | 50/75/100/150mm |

| Material of steel sheet | Color/ stainless steel |

| Thickness of color steel sheet | 0.2-1.0mm |

| Color of top / back steel | Any RAL Colors ,usually white-gray/sea blue/red; customized |

| Density of interlayer | 30-60KG/CBM |

| Length | Customized |

| Sound insulation | 21.5 dB(A) |

Installation