Focuses On Professional Cleanroom Project And Pharmaceutical Cleanroom Equipment.

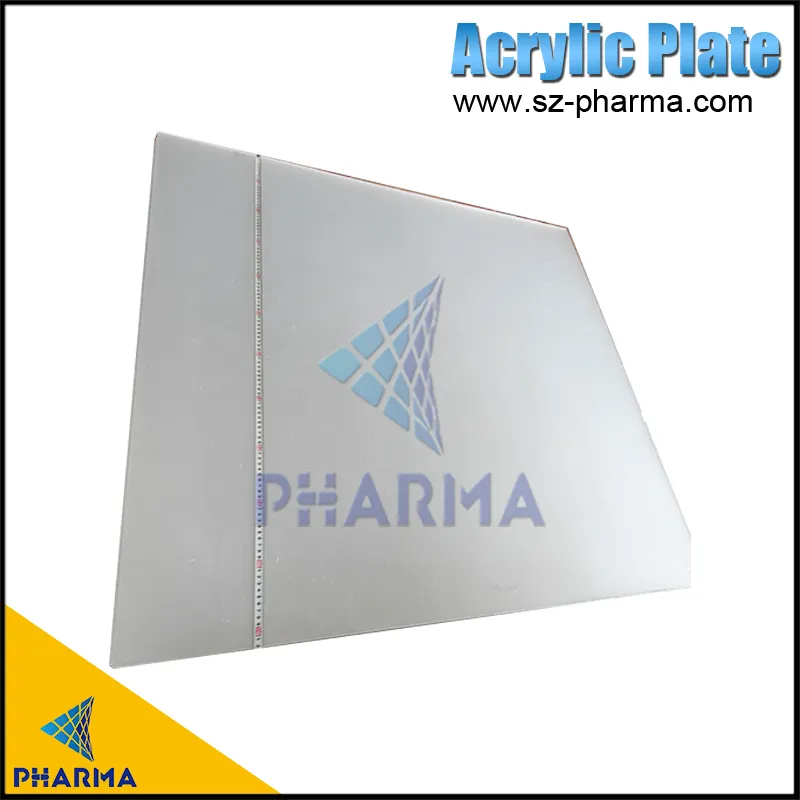

Highly transparent, anti-static, antibacterial acrylic panel

Installation and maintenance aspects

1. Lightweight: Compared to some other building materials, acrylic panels are lighter in weight, making them easier to handle and install. This can reduce installation difficulty and costs, while also reducing the burden on the cleanroom structure.

2. Easy to process: Easy to cut, drill, bend and other processing operations, can be customized according to the specific design requirements of the clean room, and made into panels of various shapes and sizes to meet different installation needs.

3. Simple maintenance: The surface is smooth, not easily contaminated with dust and dirt, easy to clean, usually only requires a mild cleaning agent and a soft cloth to wipe to maintain its transparency and cleanliness.

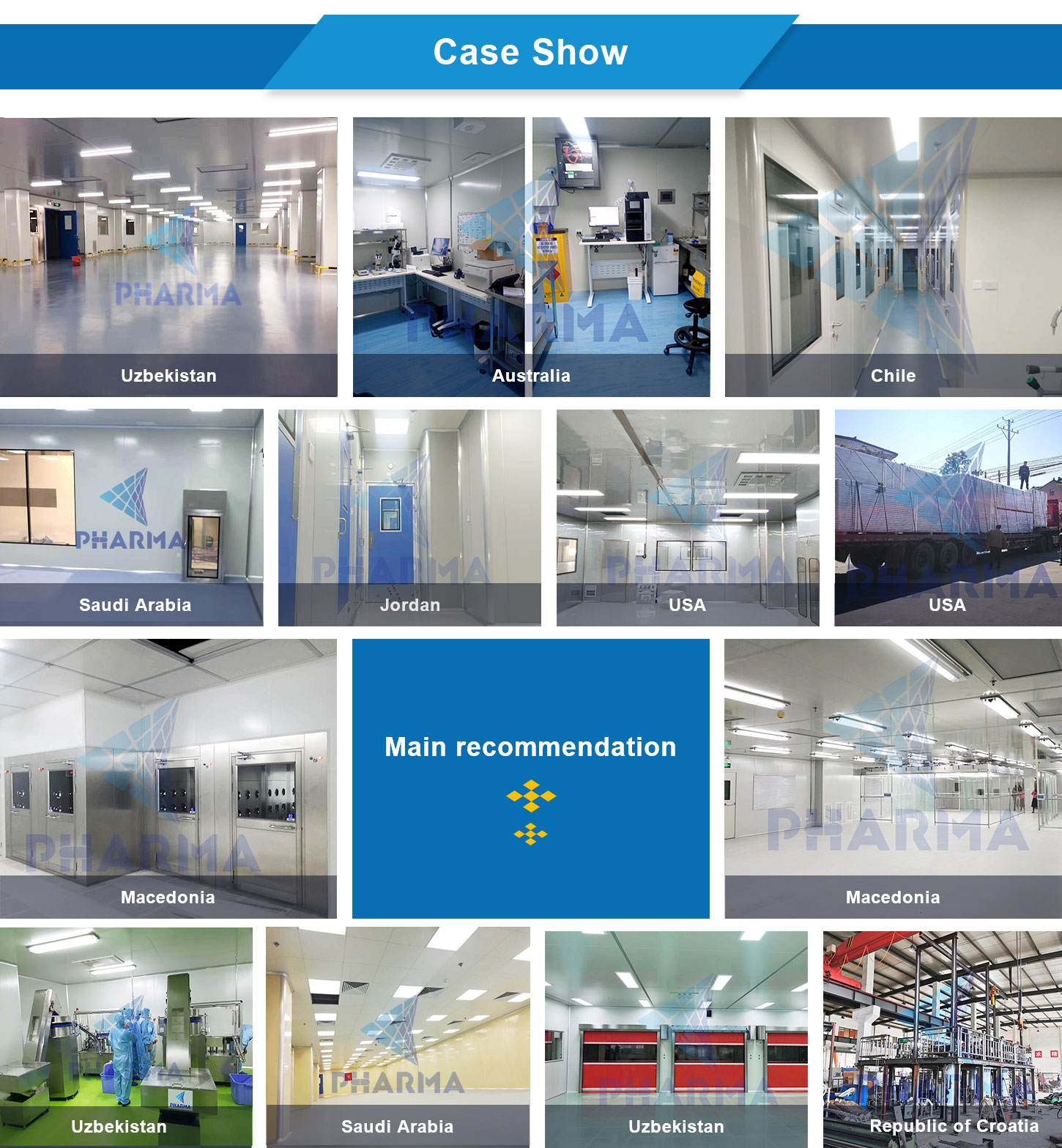

In terms of application cases

1. Electronics industry: Acrylic panels are widely used in the construction of clean rooms in semiconductor manufacturing, electronic component production, and other fields. For example, in the chip manufacturing workshop, a highly clean environment is required to prevent dust particles from damaging the chips. Anti static acrylic panels can effectively prevent static electricity from adsorbing dust, while high transparency facilitates operators to observe the operation of production equipment.

2. Pharmaceutical industry: Aseptic production workshops, laboratories, and other places in pharmaceutical factories have extremely high requirements for cleanliness and hygiene. Antibacterial acrylic panels can inhibit bacterial growth, ensure that the drug production process is not contaminated by microorganisms, and provide assurance for drug quality.

3. Food industry: Food processing and packaging workshops need to prevent dust, foreign objects, etc. from entering the production area, which can affect food quality and safety. The use of acrylic panels in a clean room can provide a relatively enclosed clean environment, and its easy to clean feature also facilitates maintaining hygiene in the food production area.