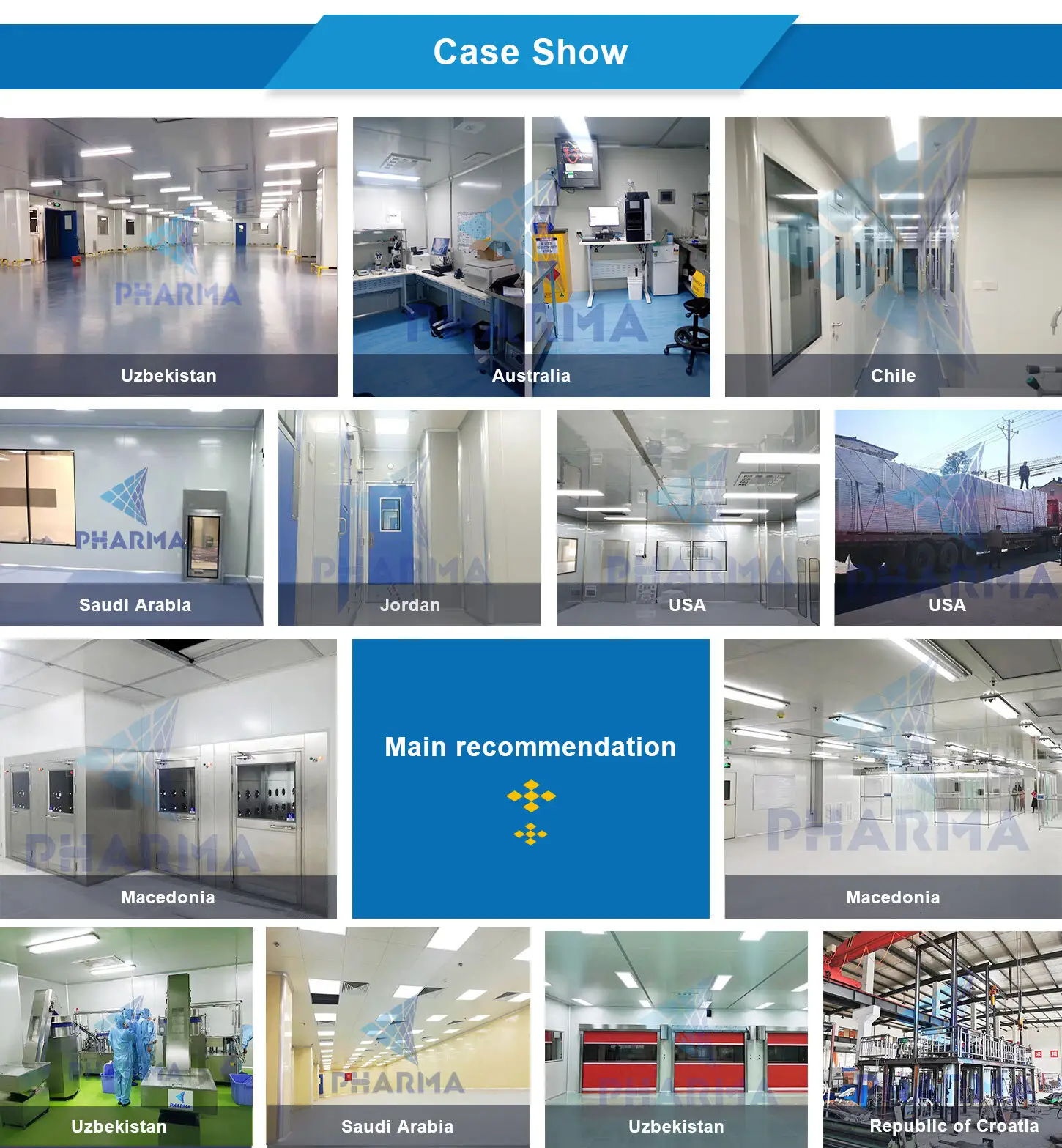

Focuses On Professional Cleanroom Project And Pharmaceutical Cleanroom Equipment.

high-energy pharma clean room buy now for chemical plant

After Warranty Service:Video technical support, Online support, Field maintenance and repair service

Warranty:1 year

Certification:CE ISO GMP

Usage:Electronic Industry

Name:Cleanroom Project

Floor:PVC

Lighting:LED

Clean grade:From Class100-10000

Power Supply:200~240V

Type:Vertical Flow

Limit Discounts

Description

The electronics manufacturing industry requires high cleanliness levels. And the air volume, temperature, humidity, pressure difference, and equipment exhaust are controlled as needed.

Among them, the requirements on humidity are even more serious, because static electricity is easily generated in overly dry workshops. Generally speaking, the temperature of the electronic workshop should be controlled at about 22, and the relative humidity should be controlled at 50-60% (special clean workshops have relevant temperature and humidity regulations)

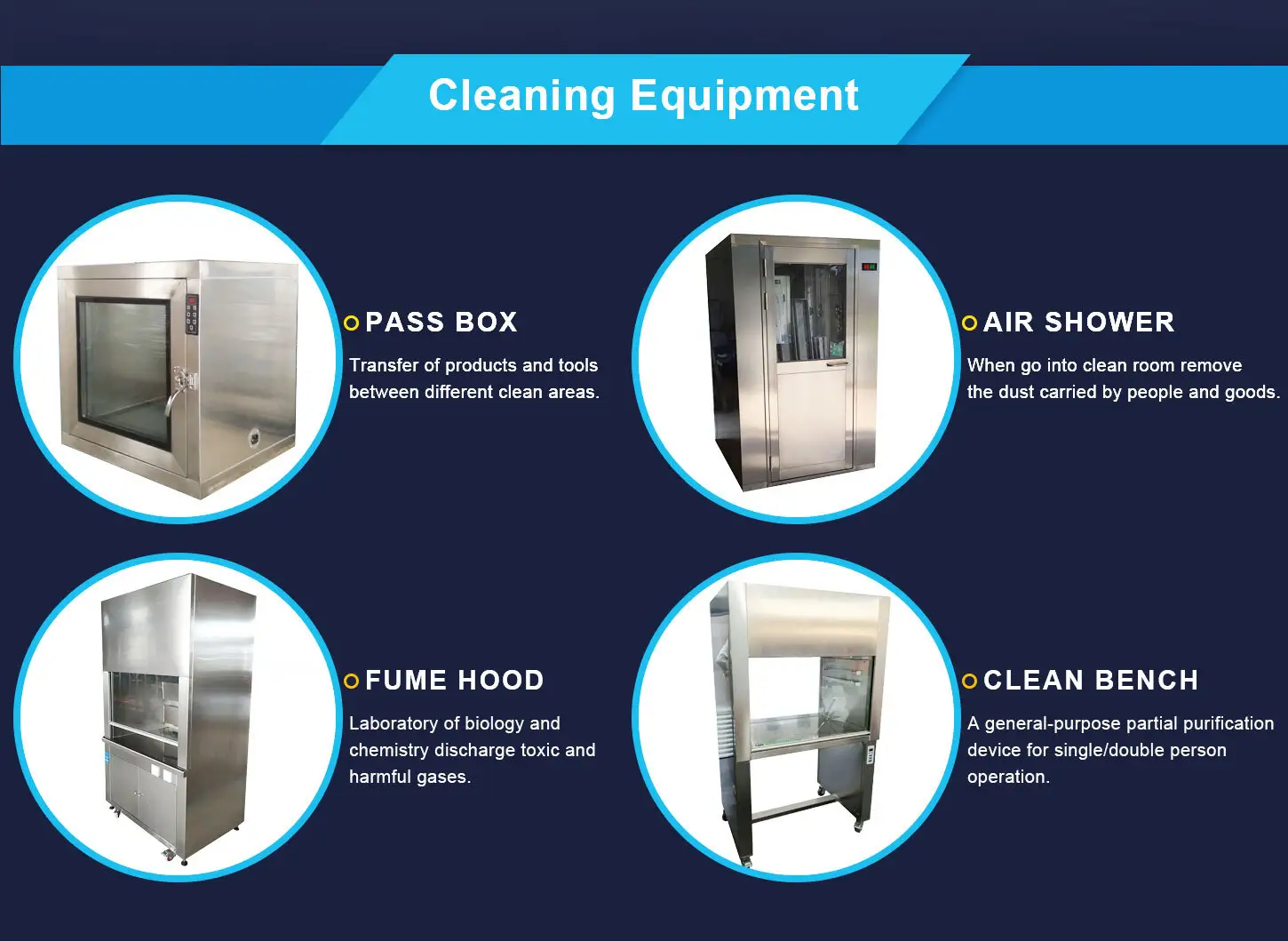

Characteristics 1. Adopt arc corner which is more suitable for the principle of clean room; 2. The system automatically controls operation, double door electronic interlock, equipped with photoelectric sensor, one-way channel air shower room, entering from the non clean area, infrared induction after the door is closed, the door is locked after the air shower, and only going out of the air shower room from the door; 3. Overall cold-rolled steel plate production, external surface electrostatic spray treatment;4. The door, base plate and nozzle are all made of stainless steel, beautiful and generous; 5. Soft key touch time relay, LED display and setting of shower time, adjustable in the range of 10-99s, double door automatic locking during shower; 6. Adopt primary and high-efficiency two-stage filtration system, with partition high-efficiency filter, with filtration efficiency of 99.99%, ensuring purification level; 7. The wind speed at the air outlet of the air nozzle is more than 25m / s, and the wind speed to the human body is more than 18m / S; 8. EVA sealing material, high sealing performance. |

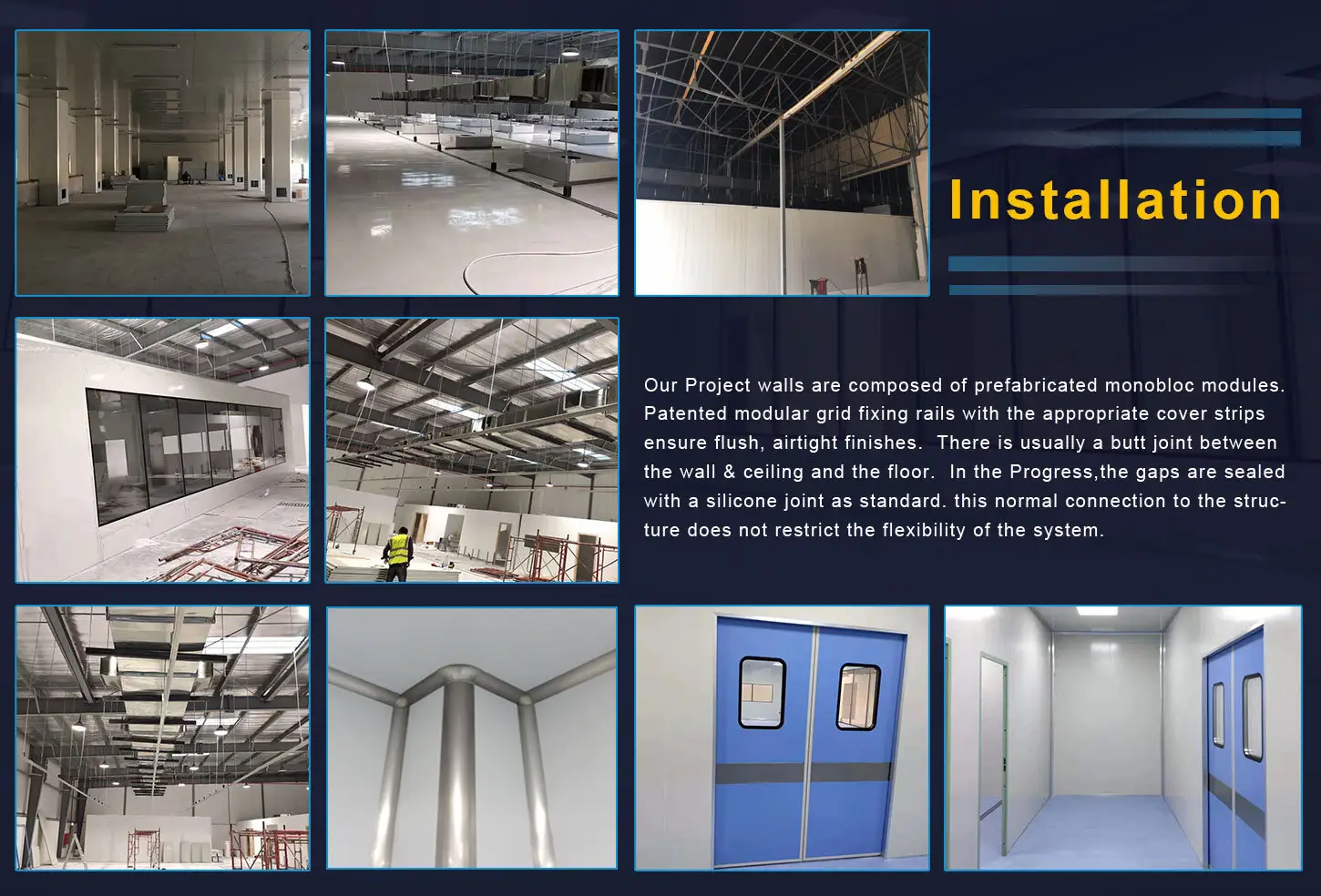

Installation

In order to know your requirement, please fill the following table carefully and supply CAD layout, so that we can provide correct scheme and quotation, thank you!

How to get a quotation >>