Focuses On Professional Cleanroom Project And Pharmaceutical Cleanroom Equipment.

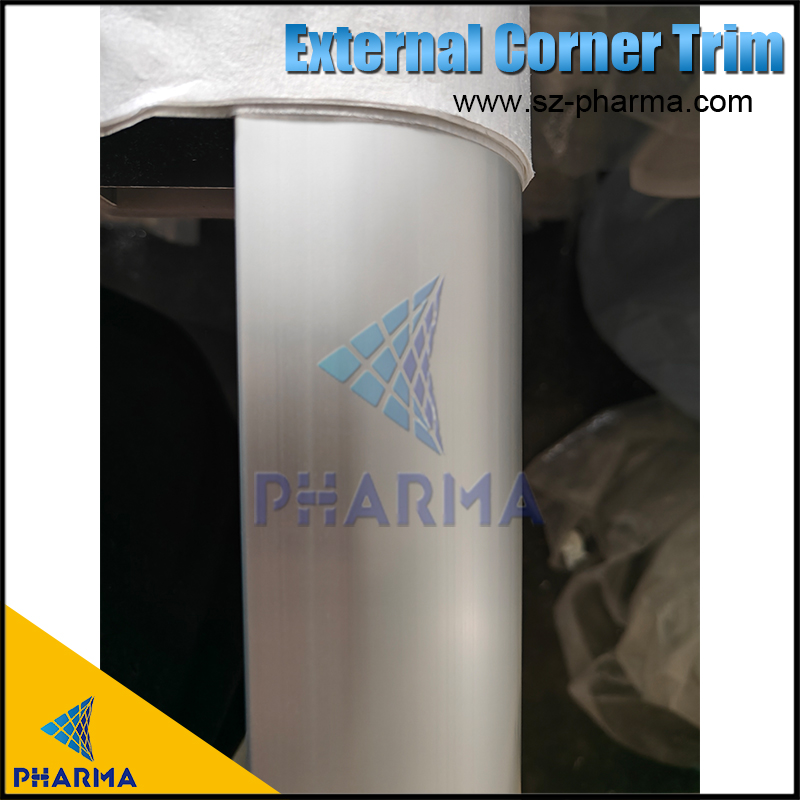

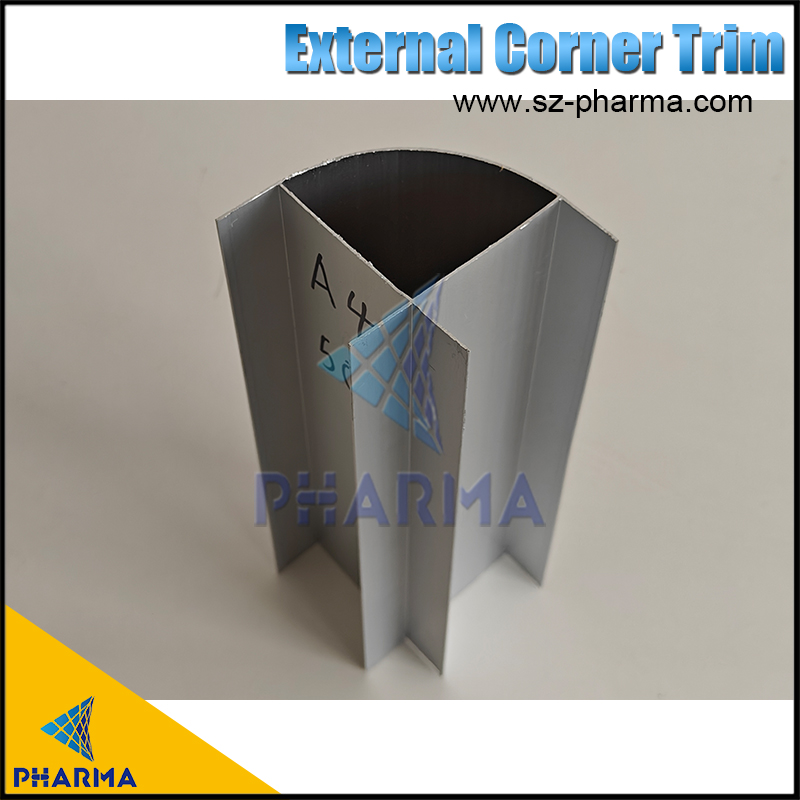

External cylindrical External Corner Trim clean room aluminum profile corner profile

After Warranty Service: Video technical support

Name: External Corner Trim

- Type: Window & Door Aluminium Profile, Decoration Aluminium Profile, Heat Sink Aluminium Profile, Transport Aluminium Profile, Industrial Aluminium Profile

Temper: T3-T8

Certification: ISO

Material: Aluminum

Description

Mainly used in dust-free workshop construction, purification projects, clean rooms, operating room decoration projects, sterile room decoration, microbiological laboratory decoration. The industries involved include: medical, food, electronics, pharmaceuticals, biological research, new energy/aerospace technology, etc., which have high requirements for dust-free and sterile environment.

A clean room refers to a room that requires a very high standard of bacteria and impurity concentration control in the internal environment. It is usually used in medical device production, drug production, and other occasions that require high cleanliness.This requires that the building materials in the clean room have high cleaning and anti-fouling capabilities.

Compared with ordinary aluminum profiles, the clean room-specific purification aluminum profile has the following characteristics:

1 Excellent surface treatment, no burrs and scratches, and reduced pollution sources.

2 Strict control of material selection to prevent the introduction of impurities and reduce particle emissions.

3 High processing precision, connection to reduce gaps.

4 Surface treatment is corrosion-resistant and increases service life.

5 Non-toxic and odorless, no VOC emissions, to ensure a clean environment.

6 Reasonable structural design, easy to clean and disinfect.

7 Quick and convenient assembly, shortening construction time.

8 Surface treatment makes it acid and alkali resistant and has a wide range of uses.

9. The color is unified and beautiful, which improves the texture of the environment.

10. High strength and light weight, which is conducive to shock absorption.

Technical Parameters

| Item | Aluminum Profile,aluminium extrusion profiles |

| Material | 6000 series Aluminium alloy |

| Temper | T4, T5, T6 |

| Size / Thickness | General profiles thickness from 0.8 to 5.0mm, length from 3m-6m or customized available; Anodize protection film thickness from 8~25 um, powder coating from 40 ~ 120 um. |

| Shape | square, round, rectangular, customized |

| Surface treatment | Anodized,Mill fninshed,Powder coating,Brushed,Polishing |

| Colors | Customized |

| Deep process | CNC, drilling, milling, cutting, welding, bending, assembling |

| MOQ | 500kgs for each item |

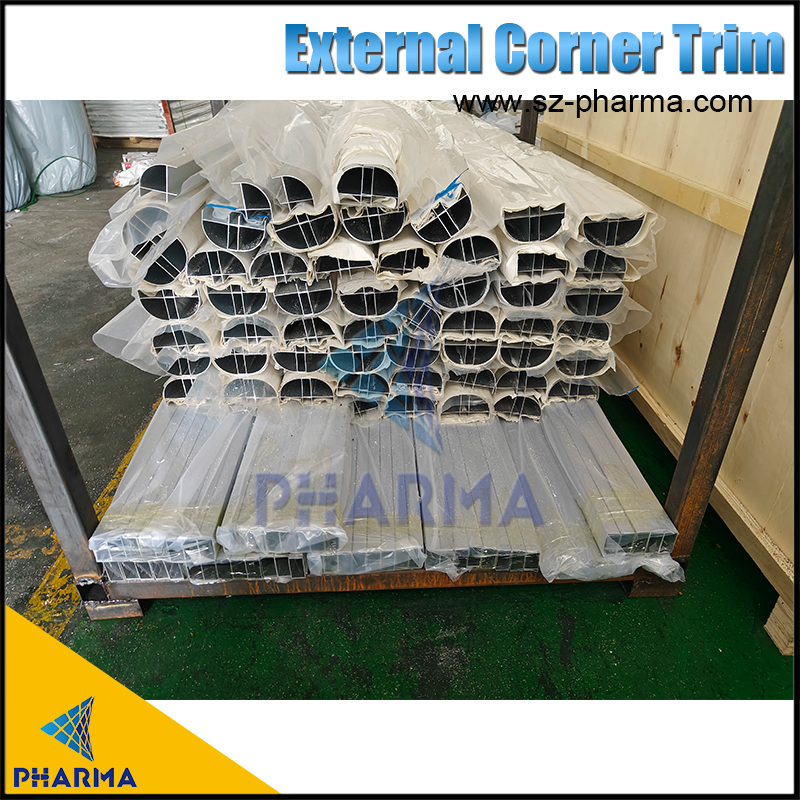

| Packing Details | (1) Inside : packed with plastic protective film to protect each piece (2) Outside: Wrap to be bundles by waterproof craft paper |

| Delivery time | (1) Die Developing and Sample testing: 12-18 days (2) Mass Production completed: 20-30days after sample is confirmed by Buyer. |

| Guarantee | Surface color can be stable for 10~20 years indoor using. |