Focuses On Professional Cleanroom Project And Pharmaceutical Cleanroom Equipment.

environmental cleanroom cleaning procedure supply for cosmetic factory

1. PHARMA iso class 4 cleanroom is manufactured using top-notch materials in conformity with the industry quality standards.

2. The product is increasingly used in the market.

3. With a built-in insulation protection system, the product is less likely to be influenced by noises caused by jamming signals or component operation.

4. This product is not easy to fade. Some dye-fixing agents have been added to its material during the production to enhance its colorfastness property.

5. The product stands out for its abrasion resistance. Its friction coefficient has been decreased by increasing the surface density of the product.

After Warranty Service:Video technical support, Online support, Field maintenance and repair service

Warranty:1 year

Certification:CE ISO GMP

Usage:Laboratories

Floor:PVC

Lighting:LED

Clean grade:From Class100-10000

Name:Cleanroom Project

Power Supply:200~240V

Type:Vertical Flow

Limit Discounts

Description

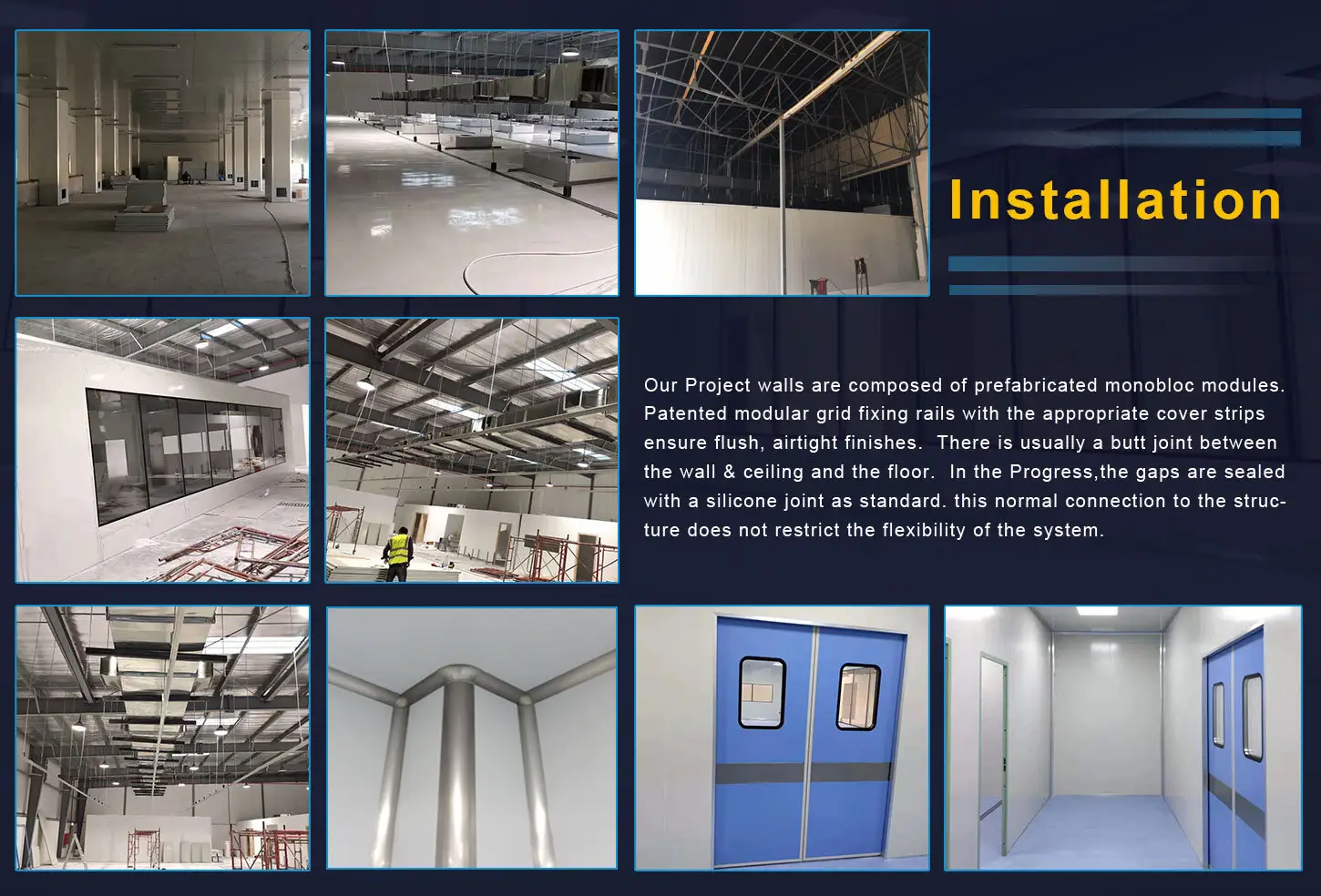

The plane and space design of the clean laboratory will arrange the clean experimental area and personnel purification, equipment and material purification and other auxiliary rooms in different areas. At the same time, the comprehensive coordination effects of various technical facilities, such as experimental operation, process equipment installation and maintenance, air distribution type, pipeline layout and purified air conditioning system, are considered.

Characteristics 1. Reasonable use of laboratory space layout 2. Meet the laboratory working environment, combined with ergonomics 3. Meet the safety requirements of the test environment If you want clean room for your Pharmaceutical or Related factory/Hospital/ Electric product factory/Plant growing green house...etc,You need provide these basic information to us: 1.What size clean room do you want to build?Do you have layout drawing? 2.What temperature and humidity do you want for your clean room?Whats local temperature and humidity? 3.What product or work will be do in the clean room? 4.Do you have factory now or just ground? 5.Whether have other special requirement? |

Technical Parameters

| Application | Solid formulations,tablets, capsules, powder formulations,etc. |

| Wall Material | Sandwich panel |

| Frame Material | 304 Stainless Steel/Aluminum alloy profile |

| Cleanliness | From Class 100 to Class 10,000,0 |

| Power | 110V/60hz/av/dc, 220V/60HZ/AV/DC |

| FFU | 2*4ft/4*4ft |

| HEPA Filter | H14 Hepa filter |

| Lighting | Available in LED and T5 |

| Size | Customize |

Installation

In order to know your requirement, please fill the following table carefully and supply CAD layout, so that we can provide correct scheme and quotation, thank you!

How to get a quotation >>

Company Features

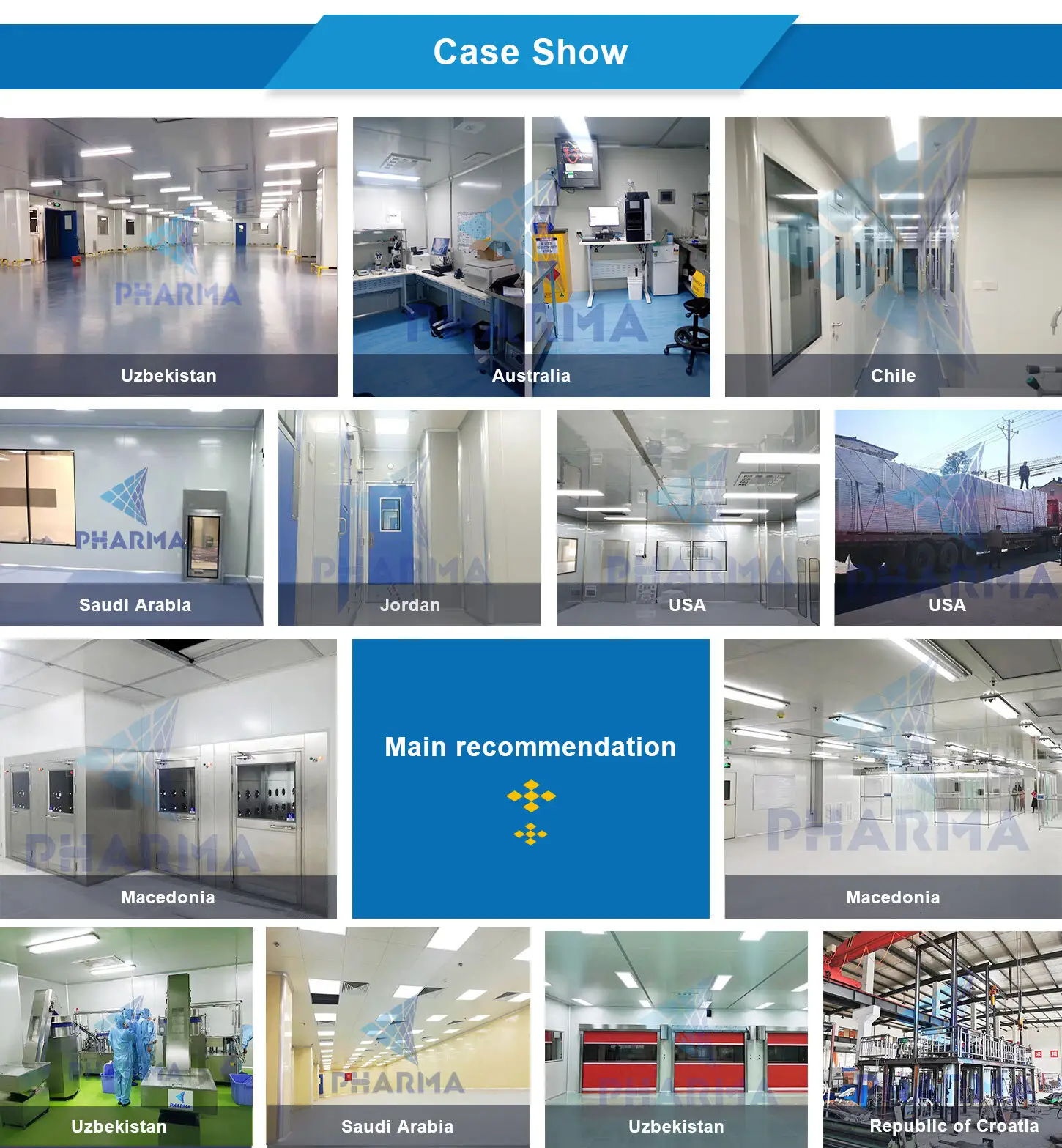

1. SUZHOU PHARMA MACHINERY CO.,LTD. provides high-end cleanroom cleaning procedure procurement services for global users. From products R&D to production, PHARMA ensures the great quality of class 100000 cleanroom .

2. Through leading technology, cleanroom hood has helped PHARMA win the recognition and trust of customers.

3. Our technology in research and development in iso 14644 cleanroom standards industry ensures the uniqueness of products. iso class 4 cleanroom is a fundamental tenet of an efficient and well-organized development for SUZHOU PHARMA MACHINERY CO.,LTD.. Call now!