Focuses On Professional Cleanroom Project And Pharmaceutical Cleanroom Equipment.

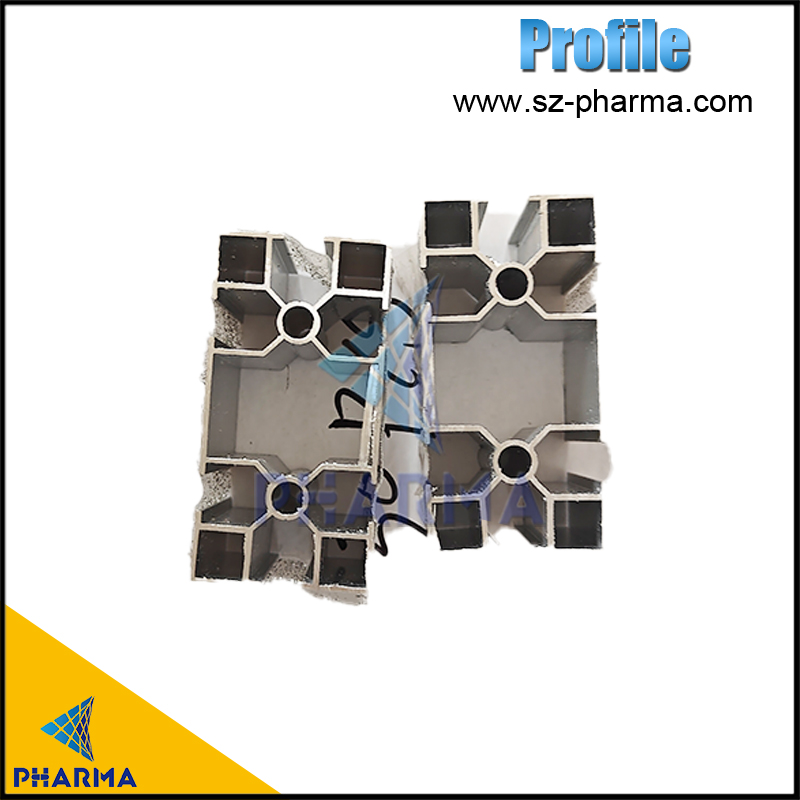

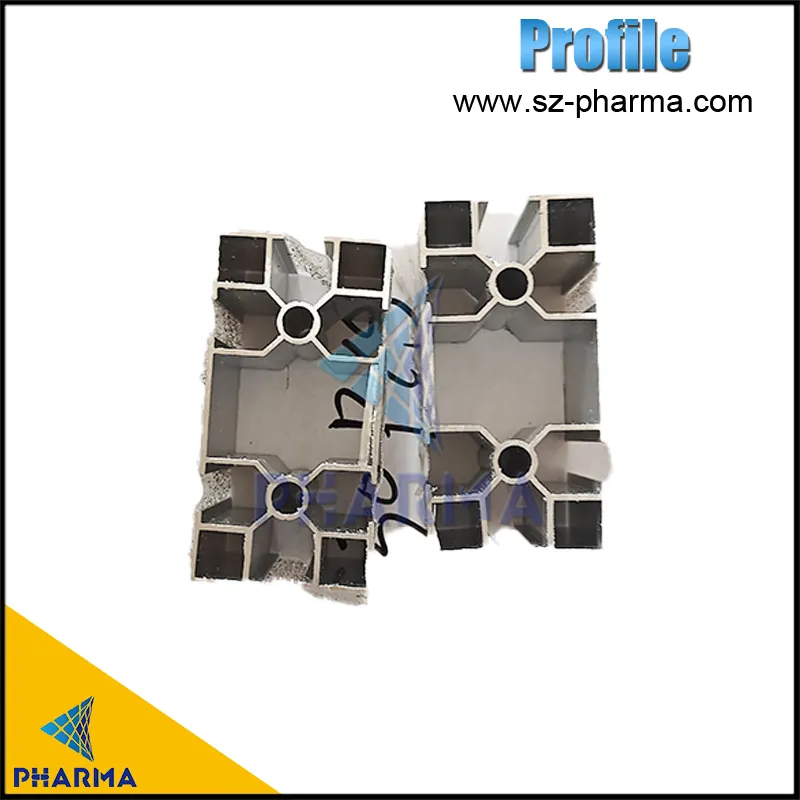

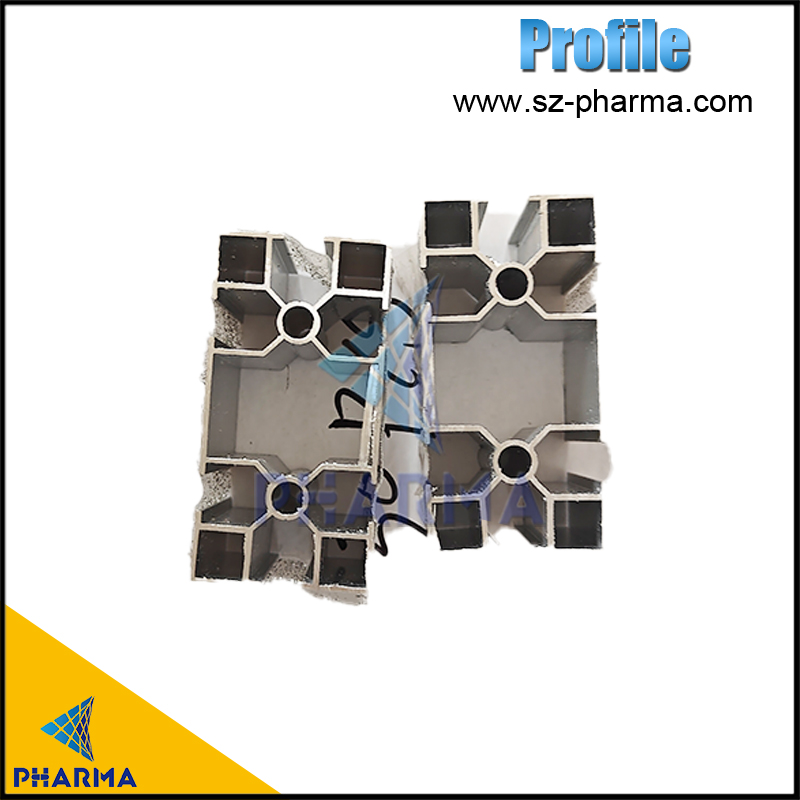

40*40 Profile Aluminum Extrusion

| (1) There are many varieties and specifications. It has reached more than 10,000 kinds, and in production, except for a few special rolling mills to produce special products, the vast majority of profile rolling mills are engaged in multi-variety and multi-specification production. (2) The cross-sectional shape is different. In the profile products, in addition to the square, round, flat steel section shape is simple and the difference is not large, most of the complex section profiles (such as I-beam, H-beam, Z-beam, channel steel, rail, etc.) not only have complex section shapes, but also differ greatly from each other, the hole design and rolling production of these products have their particularities; The complexity of the cross-sectional shape makes the deformation of each part of the metal, the temperature distribution of the cross-section and the wear of the roll uneven in the rolling process, so the size of the rolling piece is difficult to accurately calculate and control, and the adjustment of the rolling mill and the installation of the guide device are also complicated; In addition, the individual varieties or specifications of complex cross-sectional profiles are usually small in batches. The above factors make it difficult to develop the continuous rolling technology of complex cross-sectional profiles. (3) There are many forms of rolling mill structure and rolling mill layout. In the structural form, there are two-high rolling mills, three-high rolling mills, four-high universal hole rolling mills, multi-high hole rolling mills, Y-shaped rolling mills, 45° rolling mills and cantilever rolling mills. In the form of rolling mill arrangement, there are horizontal rolling mills, sequential rolling mills, checkerboard rolling mills, semi-continuous rolling mills and continuous rolling mills. |

Common classification methods for profiles

(1) Classification according to production method According to the production method, profiles can be divided into hot-rolled profiles, cold-formed profiles, cold-rolled profiles, cold-drawn profiles, extruded profiles, forged profiles, hot-formed profiles, welded profiles and special rolled profiles.

(2) Classification according to the characteristics of the section Profiles can be divided into simple cross-sectional profiles and complex cross-sectional profiles according to their cross-sectional shapes. The cross-sectional surface of simple cross-section profiles is symmetrical, and the shape is relatively uniform and simple, such as round bar, wire rod, square steel and steel bar. Complex cross-section profiles, also known as special-shaped cross-sectional profiles, are characterised by obvious convex and concave branches in the cross-section.

(3) Classification by use department Profiles are classified according to the use of the sector of railway profiles (rails, fishtail plates, turnout rails, wheels, wheel hoops), automotive profiles (rims, tyre retaining rings and lock rings), shipbuilding profiles (L-shaped steel, ball flat steel, Z-shaped steel, marine window frame steel), structural and construction profiles (H-beam, I-beam, channel steel, angle steel, crane rails, window frames and door frames, steel sheet piles, etc.), mining steel (U-shaped steel, channel steel, mining steel, scraper steel, etc.), machinery manufacturing profiles, etc.