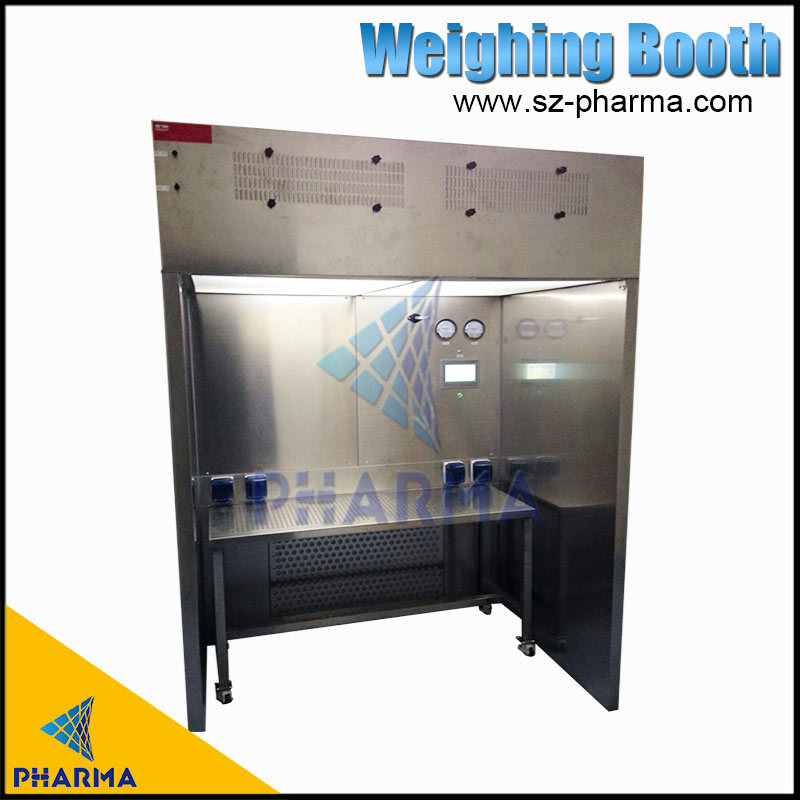

Dispensing Booth for Weighing Powder and Liquid in Pharmaceutical Cleanroom

After Warranty Service: Video technical support

Certification: CE

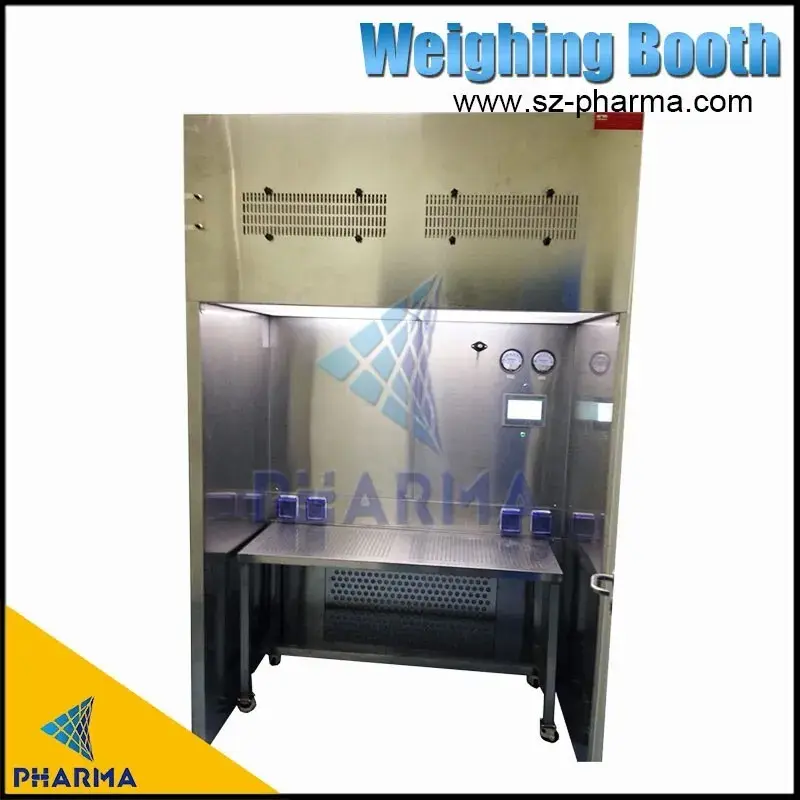

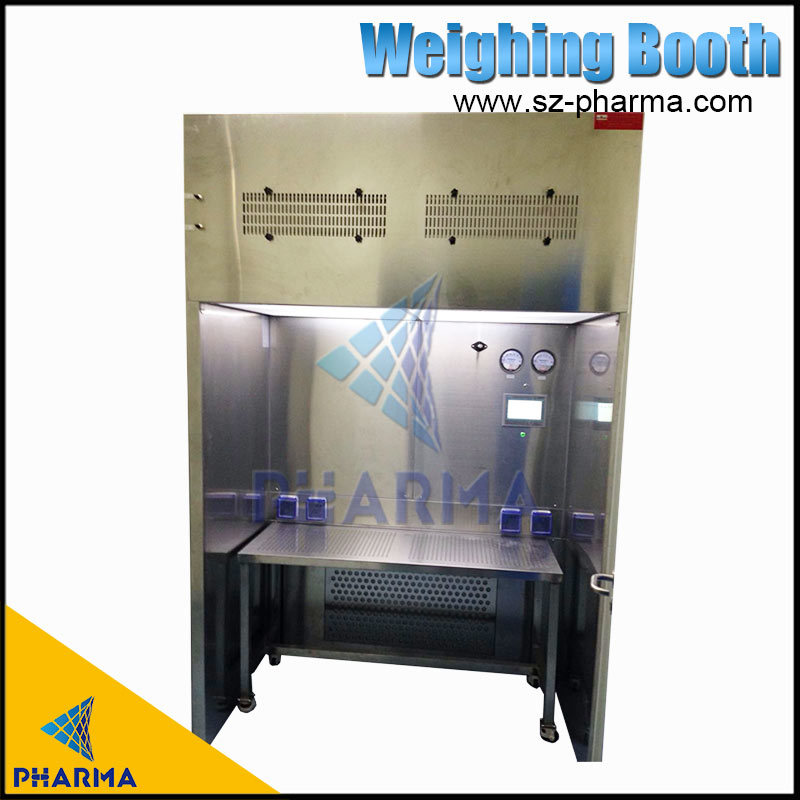

Name: Weighing Booth/dispensing booth

Control system: PLC control

Size: :1600*3000*2600mm or customize

Used: Clean room industry

Material: stainless steel 304/316

Clean grade: ISO5

Limit Discounts

Description

Dispensing booth supply according to the latest GMP requirement. The dispensing booth provides a safe environment for the operator freely weighing or measuring toxic chemicals or raw materials. Air is pulled away from user thru rear-wall pre-filters, trapping powders; recirculating air through ceiling-mounted high-efficiency particulate air (HEPA) filter rated 99.99% efficient at 0.3 microns.) Weighing booth which provides a vertical unidirectional airflow, some clean air circulation in the work area, partly discharged to the nearby area, so that the work area produce negative pressure to prevent cross contamination in order to ensure the high clean class level of the working area.

| Features: 1.With air velocity detection automatic frequency conversion system that makes the air velocity in mainly working area runs stable and uniformly. 2.Equipped with differential pressure display device which monitors each filters in real time. 3.Designed with special air duct which controls the operating noise effectively. 4.Designed with special uniform flowing in the mainly working area which protects the operating people and also protects the product from pollution or cross infection. 5.With intelligent control mode and fault alarm system, which ensures a stable operating. 6.The cabinet inside is very smooth that makes no blind corner of cleaning. 7.Humanization designed that makes the filter replacement process easier |

The negative pressure weighing chamber is composed of several parts of the working area, return air box body, air box body, air box body and outer box body. The control panel is located on the front of the working area inside the equipment. The control panel uses a light-touch LED control panel to control the start and stop of the fan, adjust the working conditions of the fan, and adjust the wind speed required in the work area. ). There is a differential pressure meter next to it, the resistance of the test filter is also inside the air supply box and there is an exhaust adjustment board, which can adjust the exhaust volume of the equipment within a reasonable range (after the equipment is installed in place, it is set by a professional Try, please do not adjust without permission)

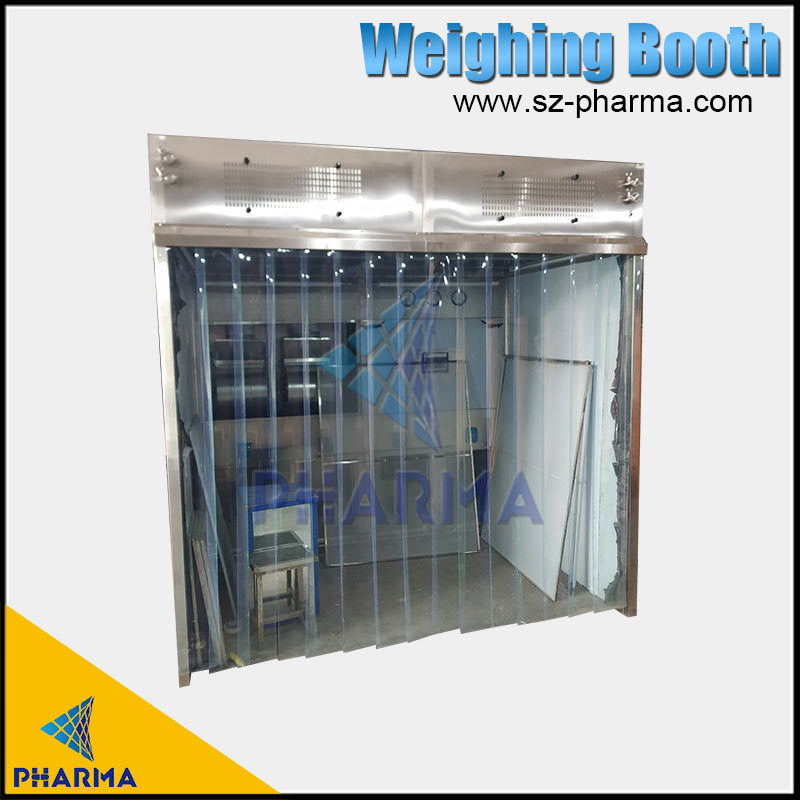

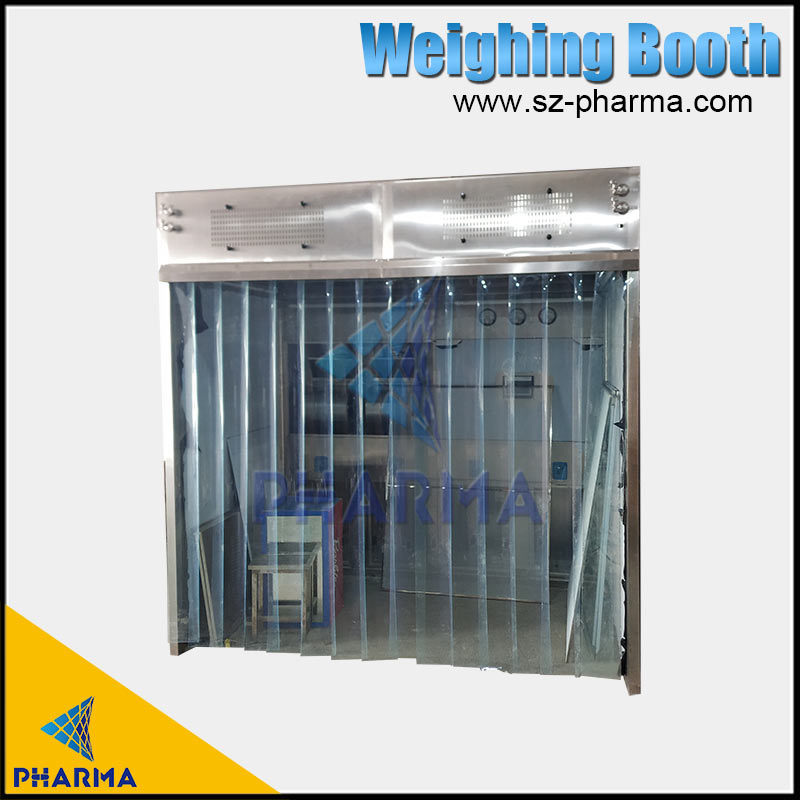

The Stainless Steel weighting room is a clean room equipment designed for weighing solid objects with dust, such as raw materials and activated carbon. It ensures that the dust of the weighing object goes down with the airflow and does not contaminate the background area, protecting the clean environment and operators health.

The Stainless Steel weighting room has the following features:

- It is made of SS304, a high-quality stainless steel material that is corrosion-resistant, durable, and easy to clean.

- It has a PVC curtain or no door, depending on the room depth, to prevent dust from escaping the working area.

- It has a vertical unidirectional airflow system, equipped with G4 plate air filter, F8 bag air filter, and H14 high efficiency air filter, to achieve the desired cleanliness level.

- It has three micro pressure meters, to detect the filter resistance and adjust the wind speed accordingly.

- It has a waterproof socket and LED lights, to provide convenience and safety for the operators.

The Stainless Steel weighting room is customizable according to your requirements. It is suitable for various industries that need precise and dust-free weighing, such as pharmaceutical, chemical, food, and biotechnology.

If you are looking for a reliable and professional manufacturer of weighing room, Suzhou Pharma Machineryis your best choice. Suzhou Pharma Machineryis an ISO9001:2008 certified factory, with more than 20 years of experience in clean room engineering and production. Suzhou Pharma Machinerycan also provide you with other clean room equipment, such as air shower, pass box, fan filter unit, laminar flow hood, and more.

Contact us to get a free quote and customize your Stainless Steel weighting room.

Technical Parameters

| Model | PH-W series |

| Internal Size (W*D*H) | 1600*3000*2600 12000*3000*2600 I 2500*3000*2600 |

| External Size (W*D*H) | 1500*2400*2000 1900*2400*2000 2500*2400*2000 |

| Class/Air Flow | ISO5 0.45±20%m/s |

| Pre-filter | G4 (90%@5um) |

| Med-filter | F8 (85%~95%@1~5um) |

| HEPA filter | H14(99.995-99.999%@0.3) |

| Power Supply | 380V/30/50Hz(Advice if different) |

| Control Mode | VFD Control/Simens PLC Control |

| Rated Power | 3kW 4kW 5kW |

| Total/Exhaust Volume | 8000/800(m3/h) 110000/1000(m3/h) | 13000/1300 |

| UV Light | Optional |

| Light Intensity | 2300Lx |

| Noise | less than 70dB (A) |

| Different Pressure Gauge(3 nos.) | 0-60Pa/0-250Pa/0-500Pa |

| Socket | P66/Qty.4 |

| MOC | SUS304/1.2mm |