Clean Room Vertical Ceiling Laminar Flow Ventilation Hood for Pharmaceutical and Laboratory

After Warranty Service: Video technical support

Certification: CE

Name: Laminar flow hood

Power supply: 220V/50Hz or Customized

Size: Customize

Used: Clean room industry

Material: stainless steel 304/316

Clean grade: ISO5

Limit Discounts

Description

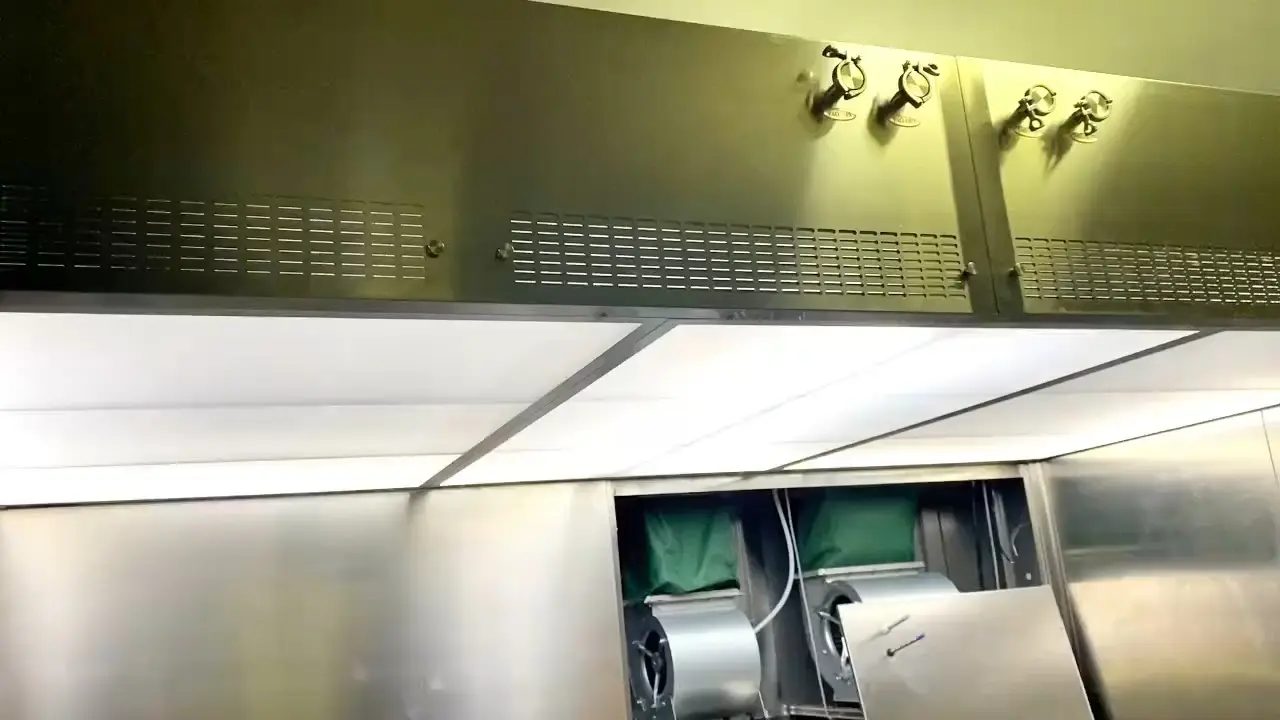

Clean laminar flow booth is a new type of structural laminar flow hood designed based on the actual situation of clean rooms, suitable for industries such as electronics, precision instruments, medical and food. Can be lifted or used in a bracket style.The laminar flow hood is made of 1.0mm 304 stainless steel welded, it can be equipped with brackets and PVC hanging curtains.Laminar air flow LAF is a ceiling unit with motors inside. It is a partial high purification equipment, which mainly consist of cabinet, fan, primary filters, HEPA filters, lamps, all flow membrane, controls and other components. The air goes through the primary filter press in static pressure box by centrifugal fan, after HEPA filter be filtered clean wind blowing out, clean air and indoor air continuously mixed and diluted to achieved purification effect.It is modular, and it can be up to 0.45m/s±20%. What is more, it is equipped with gel seal ULPA filter for good sealing.

The laminar flow hood draws air from the clean room and, through a fan installed in the top pressurized compartment, filters the air through the HEPA and vertically through the operating area, providing unidirectional air flow to the critical area. Exhaust gases are discharged from below and returned to the cleanroom area.This design ensures that the air in the work area is always clean. It is mainly used to provide a local high clean working environment. Laminar flow hood is mainly composed of box, fan, high efficiency air filter, damping layer, lamps and so on.

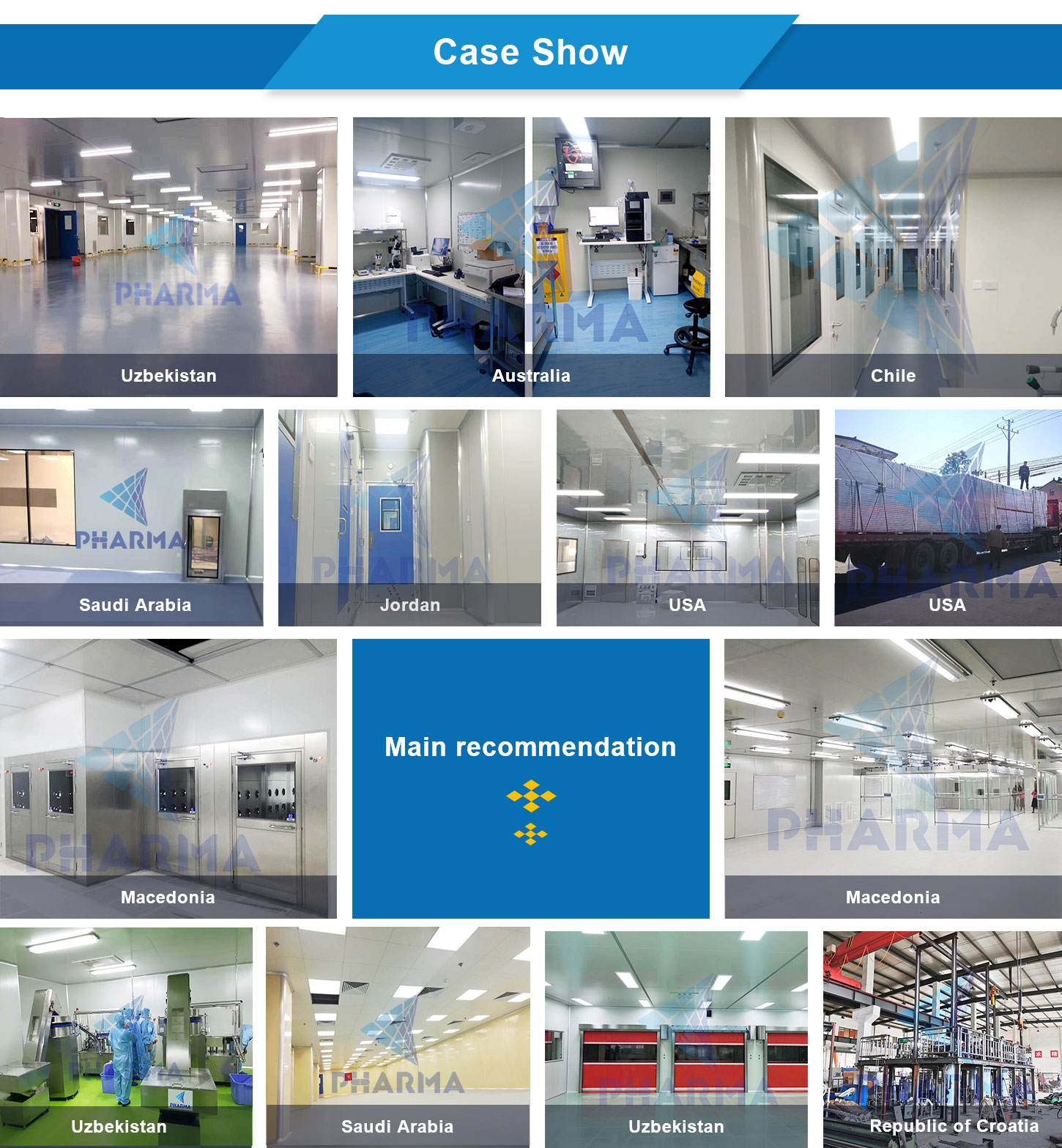

Applications

1. Pharmaceutical Production: Suitable for tablet coating, sterile drug formulation, and packaging.

2. Biotechnology Research: Provides a contaminant-free environment for sensitive processes, including cell culture and DNA/RNA manipulation.

3. Electronics Manufacturing: Ideal for assembly and inspection of components, including semiconductors and microchips.

4. Aseptic Processing: Ensures sterile conditions for the preparation of medical devices, injectable drugs, and other critical products.

5. Food and Beverage Processing: Protects food and beverage ingredients during packaging and filling processes, ensuring safety and compliance with hygienic standards.

6. Laboratory Applications: Suitable for microbiology, chemical analysis, and quality control testing where contamination-free environments are essential.

| Product Features:

|

Technical Parameters

| Model | PH-W series |

| Internal Size (W*D*H) | 1600*3000*2600 12000*3000*2600 I 2500*3000*2600 |

| External Size (W*D*H) | 1500*2400*2000 1900*2400*2000 2500*2400*2000 |

| Class/Air Flow | ISO5 0.45±20%m/s |

| Pre-filter | G4 (90%@5um) |

| Med-filter | F8 (85%~95%@1~5um) |

| HEPA filter | H14(99.995-99.999%@0.3) |

| Power Supply | 380V/30/50Hz(Advice if different) |

| Control Mode | VFD Control/Simens PLC Control |

| Rated Power | 3kW 4kW 5kW |

| Total/Exhaust Volume | 8000/800(m3/h) 110000/1000(m3/h) | 13000/1300 |

| UV Light | Optional |

| Light Intensity | 2300Lx |

| Noise | less than 70dB (A) |

| Different Pressure Gauge(3 nos.) | 0-60Pa/0-250Pa/0-500Pa |

| Socket | P66/Qty.4 |

| MOC | SUS304/1.2mm |