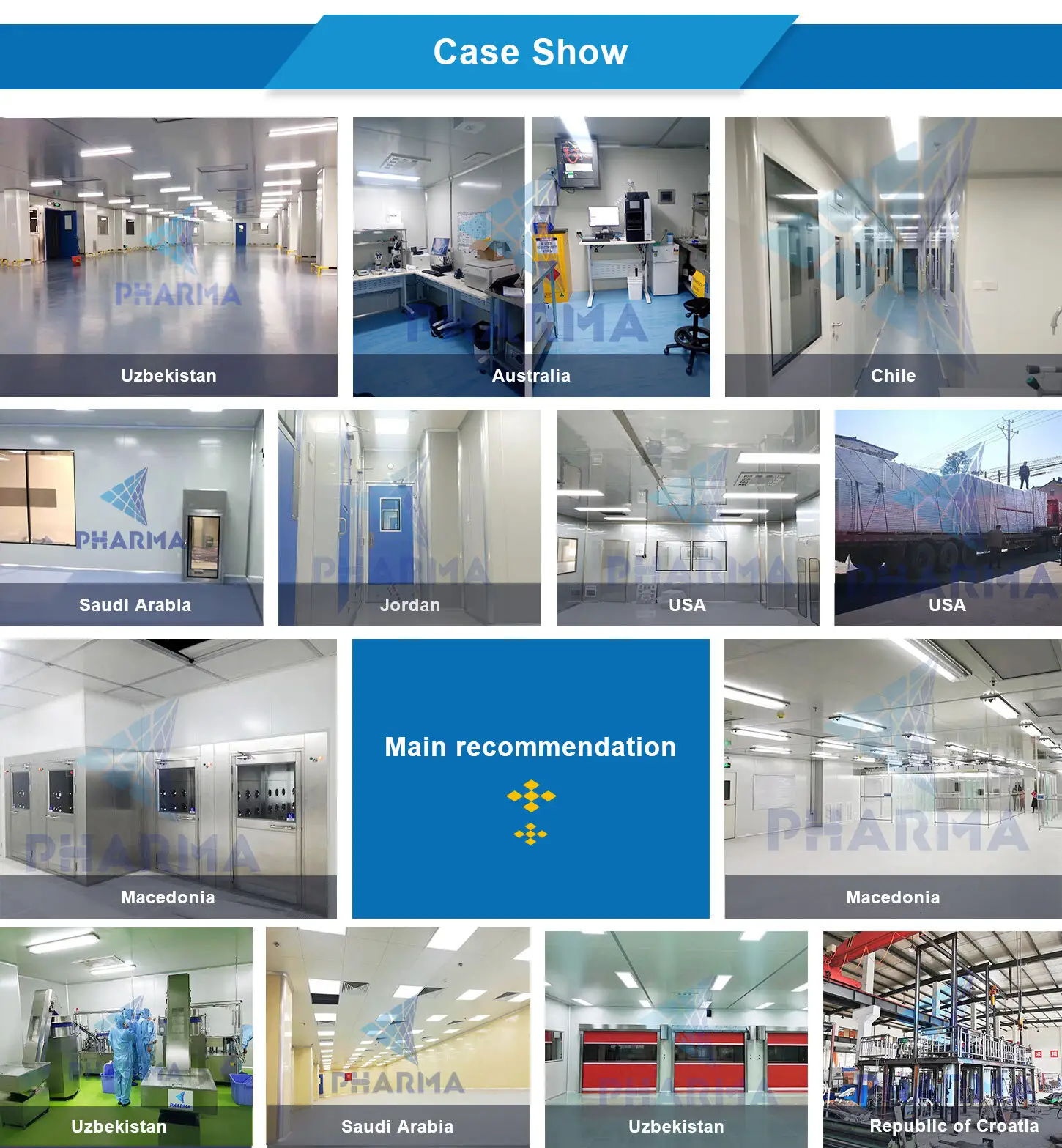

Focuses On Professional Cleanroom Project And Pharmaceutical Cleanroom Equipment.

stable fan filter unit free design for chemical plant

After Warranty Service:Video technical support, Online support

Warranty:1 year

Certification:ISO9001, ISO CE

Efficiency:99.995%@0.3μm

Size:Customized

Color:White

Medium Material:Paper,glass fiber,cotton

Porosity:0.5um, 0.3um

Frame:Extruded aluminum,galvanized steel sheet

Construction:Panel Filter

Limit Discounts

Description

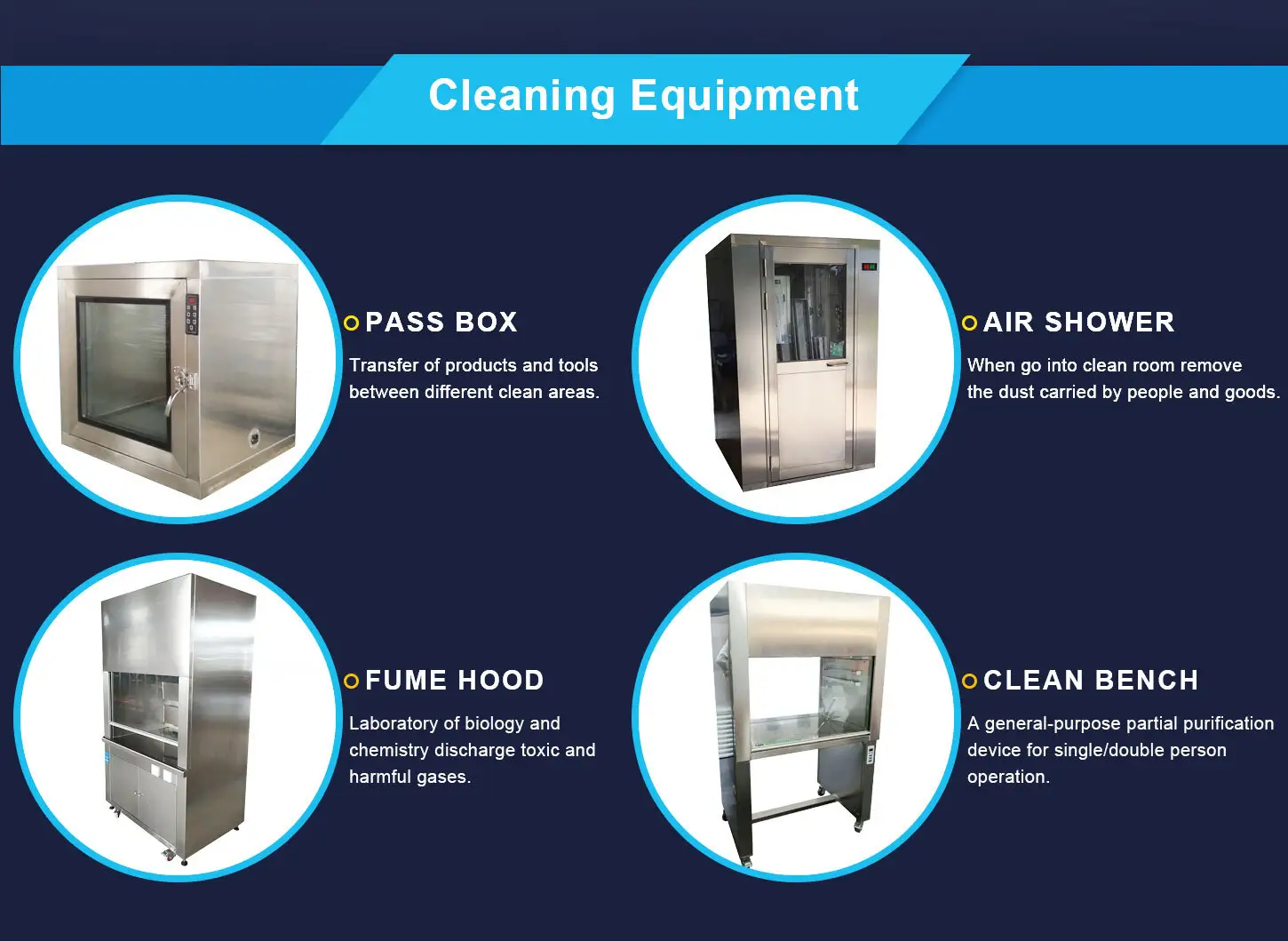

Air filter refers to the air filter device, which is generally used in clean workshop, laboratory and dust free cleanrooms, or used for clean room equipment, air shower, pass box, clean bench, weighing booth, safety cabinet, etc. There are five types of air filter: primary filter, medium efficiency filter, high and medium efficiency filter and sub high efficiency and high efficiency filter. Different models have different standards and performance.

Characteristics 1. Air filter screen is made of very small organic fibers. The ability to capture particles is stronger, small pore size, large adsorption capacity,small wind resistance, and high filtration accuracy; 2. Filtration efficiency: efficiency varies according to material. 3. According to the equipment's air flow requirements, installation size requirements, filtering efficiency and resistance requirements to selection and design; 4. Application: cleanroom system, air clean equipment, fresh air machine, air conditioning, electronic industry, medical equipment, etc. 5. With functions perfect large scale group control operating system |

Technical Parameters

| Structure | Dimensions | Airflow | Early resistanc | Recommended endresistance |

| Chip | 290*595*20(mm) | 1240(CMH) | 95(Pa) | 120(Pa) |

| 493*595*20(mm) | 2110(CMH) | |||

| 595*595*20(mm) | 2540(CMH) | |||

| 290*595*46(mm) | 1240(CMH) | 60(Pa) | 80(Pa) | |

| 493*595*46(mm) | 2110(CMH) | |||

| 595*595*46(mm) | 2540(CMH) | |||

| Pleated | 290*595*46(mm) | 1240(CMH) | 40(Pa) | 62(Pa) |

| 493*595*46(mm) | 2110(CMH) | |||

| 595*595*46(mm) | 2540(CMH) |

| Filter level | Filtration accuracy | Filtration efficiency |

| G1 (EN779) | ≥5um | 40% |

| G2 (EN779) | ≥5um | 70% |

| G3 (EN779) | ≥5um | 85% |

| G4 (EN779) | ≥5um | 90% |

| F5 (EN779) | 1- 10um | 35% |

| F6 (EN779) | 1-10um | 45% |

| F7 (EN779) | 1-10um | 65% |

| F8 (EN779) | 1-1 0um | 85% |

| F9 (EN779) | 1-1 0um | 95% |

| H10 (EN1 8822) | ≥0.3um | 90% |

| H11 (EN18822) | ≥0.3um | 99% |

| H12 (EN1 8822) | ≥0.3um | 99.90% |

| H13 (EN1 8822) | ≥0.3um | 99.99% |

| H14 (EN18822) | ≥0.3um | 100.00% |

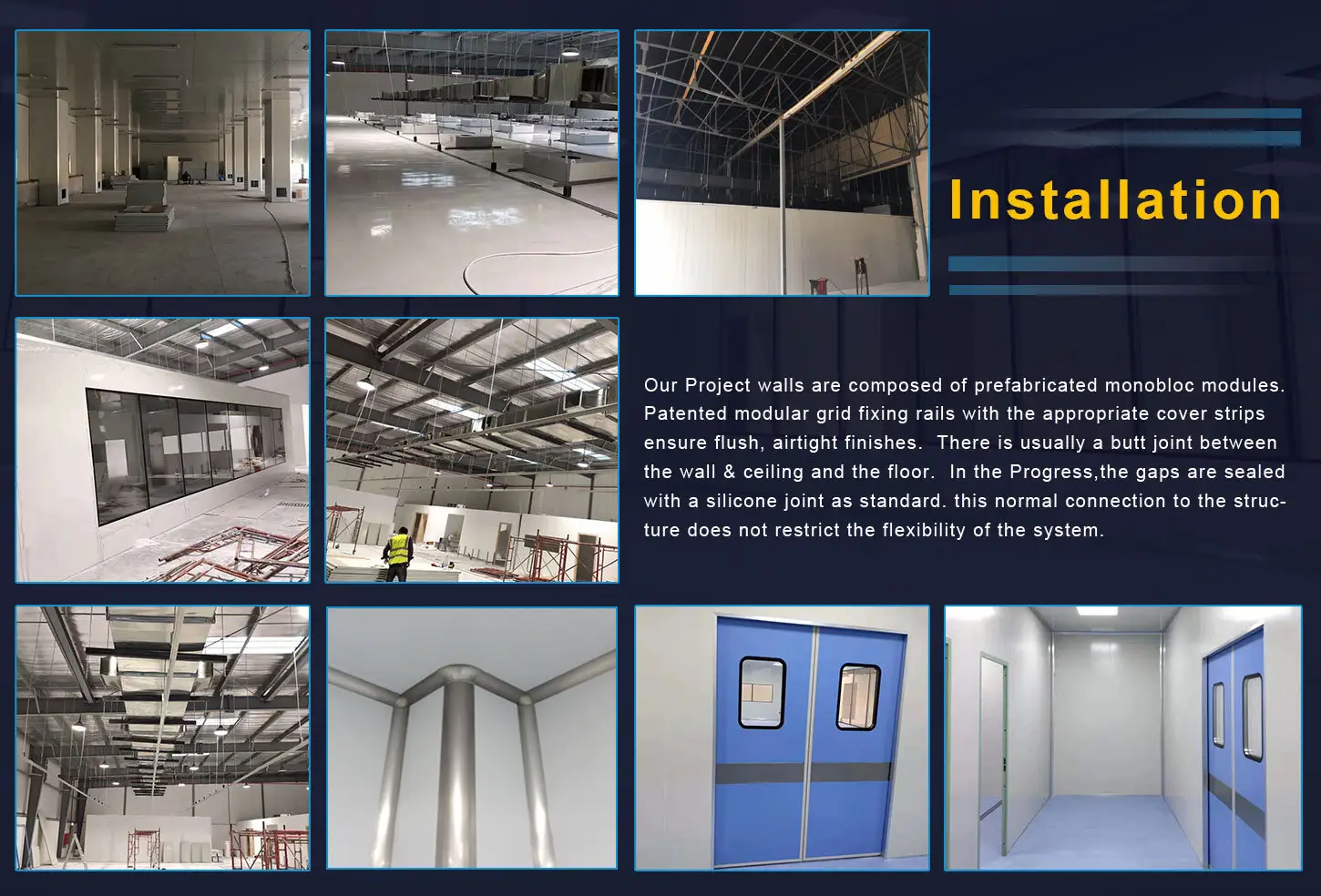

Installation