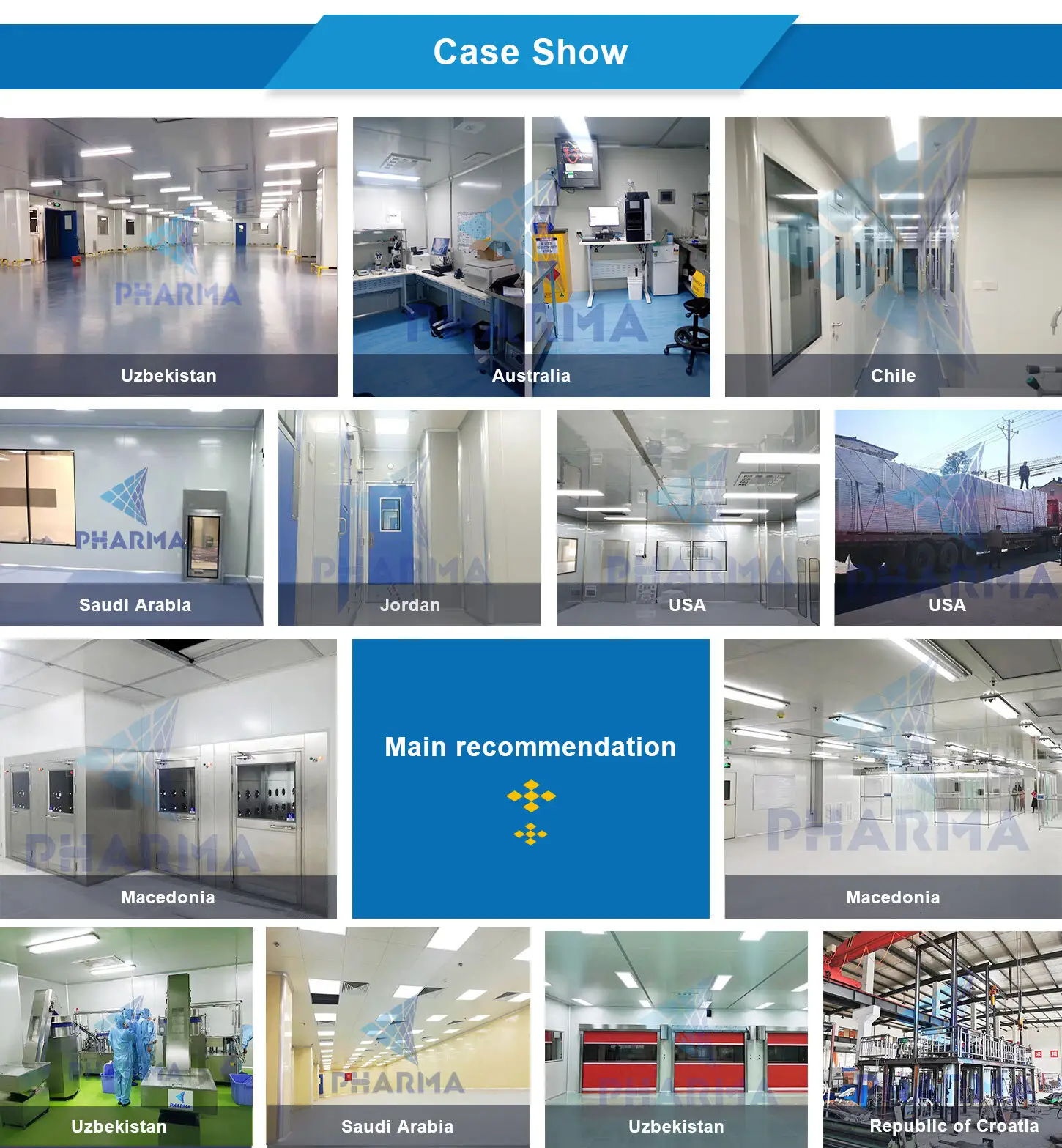

Focuses On Professional Cleanroom Project And Pharmaceutical Cleanroom Equipment.

professional iso class 7 cleanroom requirements China for cosmetic factory

After Warranty Service:Video technical support, Online support, Field maintenance and repair service

Warranty:1 year

Certification:CE ISO GMP

Usage:Laboratories

Floor:PVC

Lighting:LED

Clean grade:From Class100-10000

Name:Cleanroom Project

Power Supply:200~240V

Type:Vertical Flow

Limit Discounts

Description

The plane and space design of the clean laboratory will arrange the clean experimental area and personnel purification, equipment and material purification and other auxiliary rooms in different areas. At the same time, the comprehensive coordination effects of various technical facilities, such as experimental operation, process equipment installation and maintenance, air distribution type, pipeline layout and purified air conditioning system, are considered.

Characteristics 1. Reasonable use of laboratory space layout 2. Meet the laboratory working environment, combined with ergonomics 3. Meet the safety requirements of the test environment If you want clean room for your Pharmaceutical or Related factory/Hospital/ Electric product factory/Plant growing green house...etc,You need provide these basic information to us: 1.What size clean room do you want to build?Do you have layout drawing? 2.What temperature and humidity do you want for your clean room?Whats local temperature and humidity? 3.What product or work will be do in the clean room? 4.Do you have factory now or just ground? 5.Whether have other special requirement? |

Technical Parameters

| Application | Solid formulations,tablets, capsules, powder formulations,etc. |

| Wall Material | Sandwich panel |

| Frame Material | 304 Stainless Steel/Aluminum alloy profile |

| Cleanliness | From Class 100 to Class 10,000,0 |

| Power | 110V/60hz/av/dc, 220V/60HZ/AV/DC |

| FFU | 2*4ft/4*4ft |

| HEPA Filter | H14 Hepa filter |

| Lighting | Available in LED and T5 |

| Size | Customize |

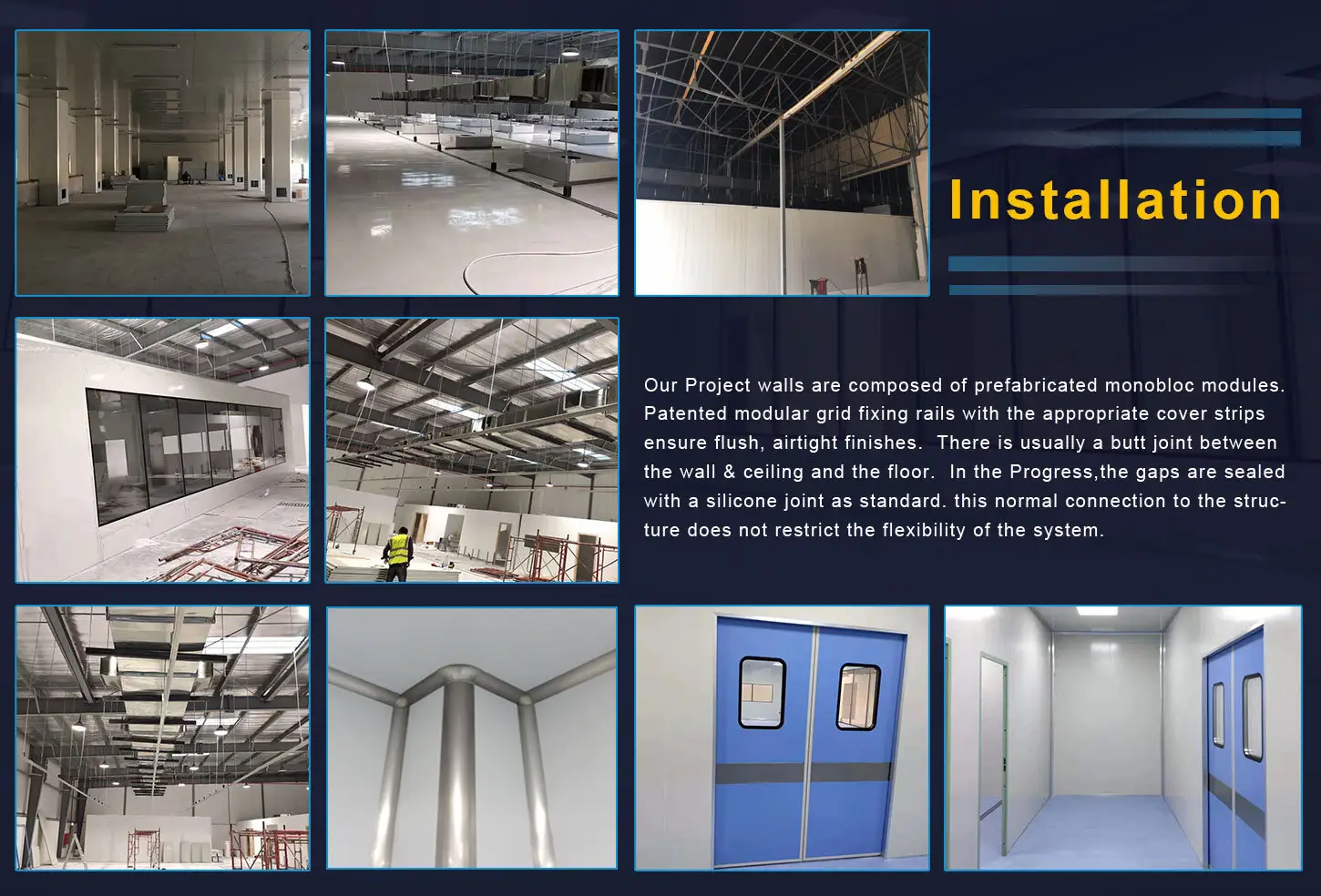

Installation

In order to know your requirement, please fill the following table carefully and supply CAD layout, so that we can provide correct scheme and quotation, thank you!

How to get a quotation >>