Focuses On Professional Cleanroom Project And Pharmaceutical Cleanroom Equipment.

PHARMA softwall cleanroom supply for chemical plant

Service:Video technical support, Online support, Field maintenance ,repair service

Warranty:1 year

Certification:CE ISO GMP

Usage:Hospital/Pharmacy/Medical/workshop

Floor:clean room PVC 2mm Homogeneous floor

Lighting:LED (CE UL)

Clean grade:From Class100-100000

Name:clean room project

Power Supply:AC 100~240V 1 phase,AC 220~480V 3 phase

Type:Vertical Air Flow

Limit Discounts

Description

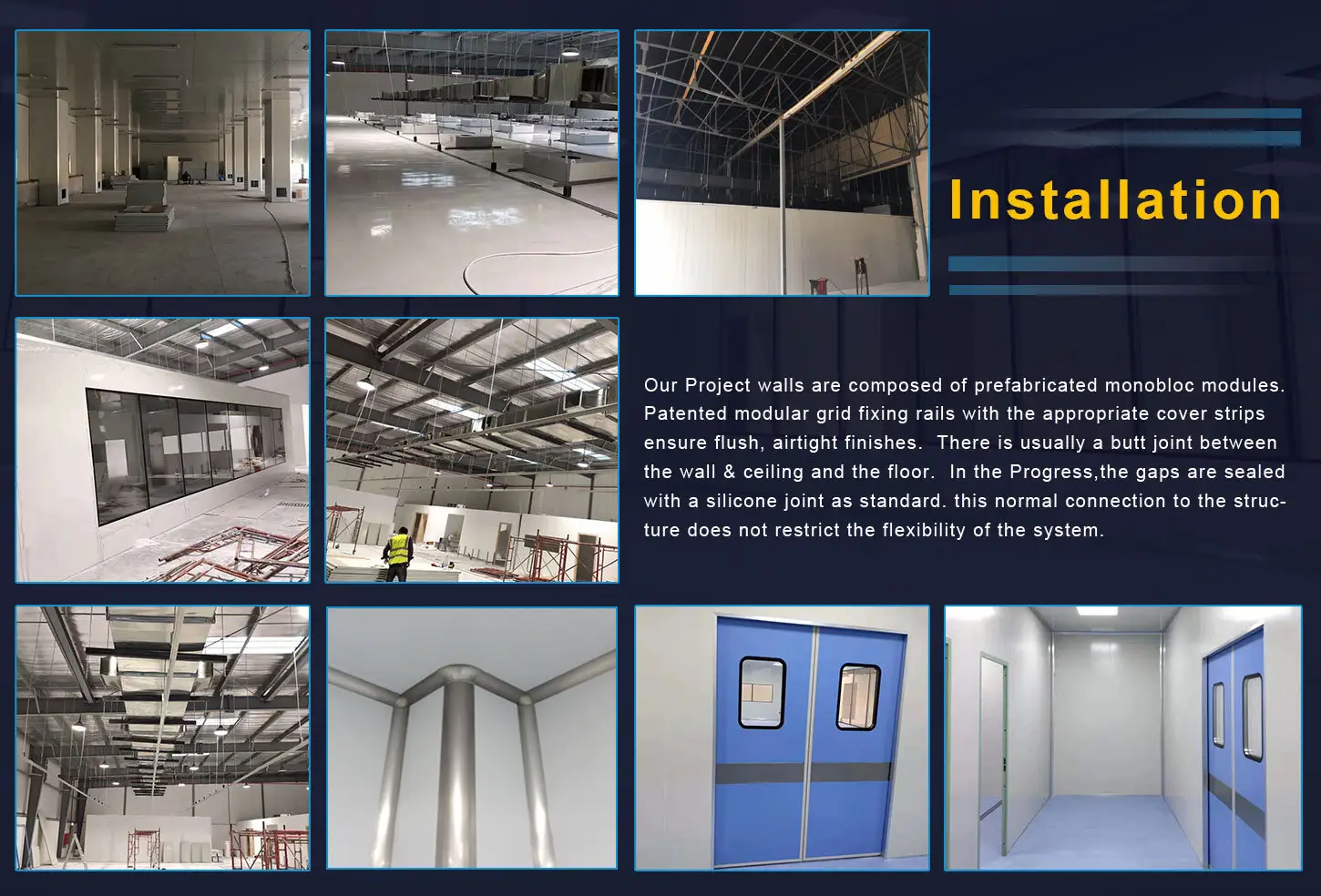

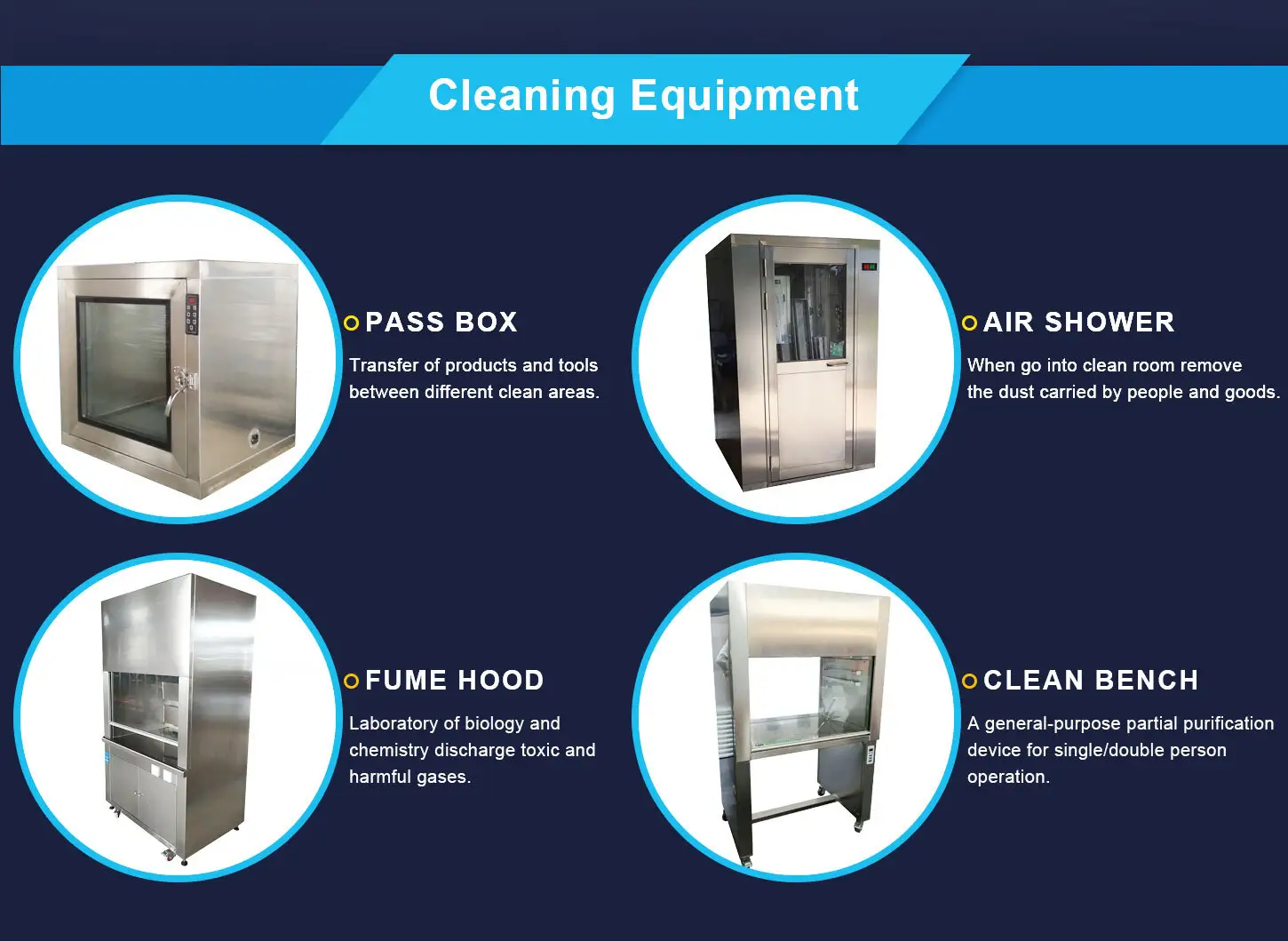

Clean room projects, usually more than 200 square meters, need to be equipped with HVAC system. It is mainly used in large pharmaceutical workshop, medical equipment production, food production, electronic product production, etc. Including transfer window, air shower room and other air purification products, to ensure strict implementation of GMP and other relevant cleanliness requirements. The turnkey project requires that while designing the clean room, the equipment selection, capacity calculation and layout of the clean workshop should be completed. The design cycle will be relatively long. The construction period is 30-40 days. We provide complete construction drawings and design drawings. The delivery time is 20-30 days, and the production of HVAC equipment needs about 30 days.

Characteristics 1 Professional negotiation and communication, complete layout design in 3 days 2 GMP clean room standard design. 3 Export wooden case packing, quick customs clearance. 4 Complete installation drawing, online guide installation and debugging. 5. Customers can customize HVAC to realize air supply, return and fresh air duct system. 6. Turnkey project, provide one-stop procurement, provide all production equipment |

Technical Parameters

| Cleanliness | Class 100 to Class 100000, ISO 5 to ISO 8, Class B to Class D |

| Project include | 1. Structure: Wall Panel, Ceiling Panel, Windows, Doors, Various Fittings, Flooring |

| 2.Electric: Lighting, Switch, Cables, Wires, Power Distribution Cabinet, etc | |

| 3.HVAC: AHU, Ducting, Piping, Chiller, dehumidifier, etc. | |

| 4.Auto-control system: PLC Controller, Sensors of Humidity and Temperature for keeping right value | |

| 5. Process Piping System: Gas, Water Pipeline | |

| Temperature&Humidity | As clients request |

| Application | Pharmaceutical Industry |

| Qualification Documents | ISO,CE |

| Our Service | Professional Consultation, User-friendly English Sofaware, 24 hours technical support,Foreign installation and commissioning |

Installation

In order to know your requirement, please fill the following table carefully and supply CAD layout, so that we can provide correct scheme and quotation, thank you!

How to get a quotation >>