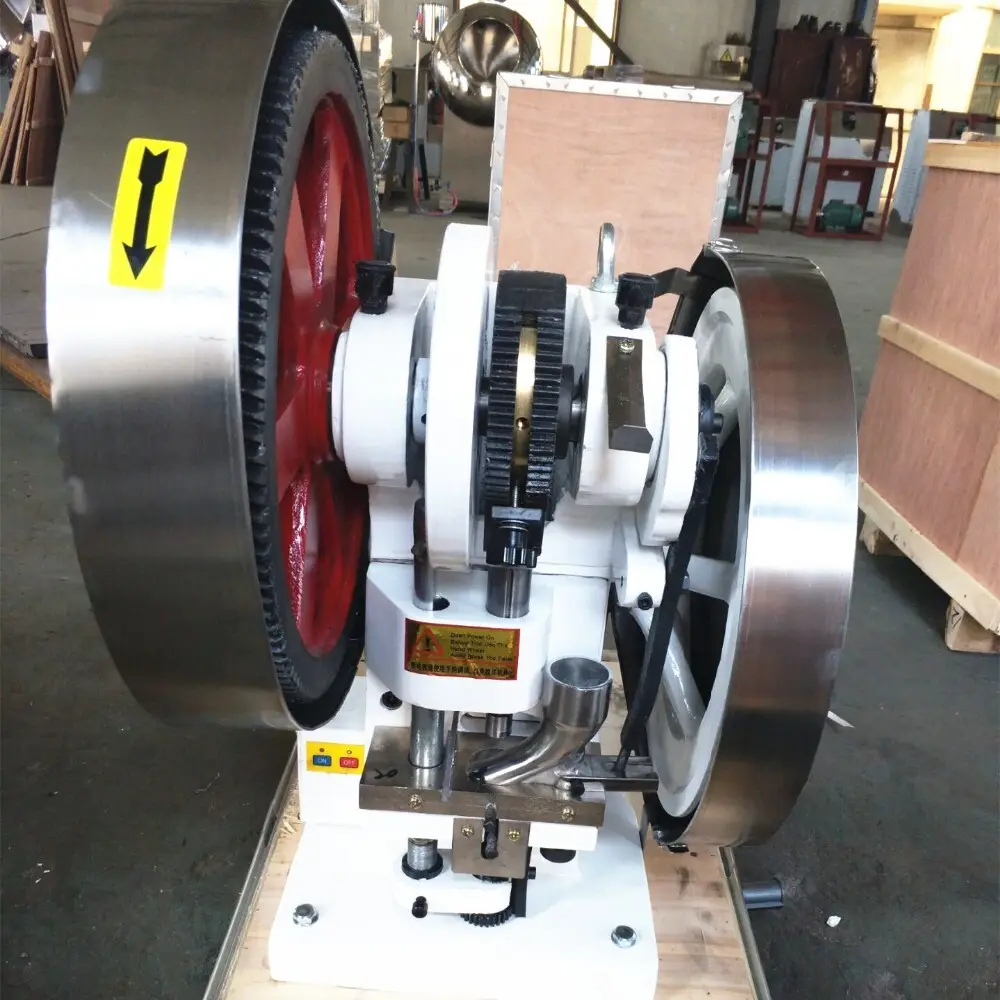

This machine is designed for pressing round tablets from various granular materials, applicable to be used for research and development and to small scale production. As its feature, it is an all desk-top continuous press driven by motor or man power. Only one set of punch and die is mounted. The depth of the filling material and the thickness of the tablets can be adjusted.

Focuses On Professional Cleanroom Project And Pharmaceutical Cleanroom Equipment.

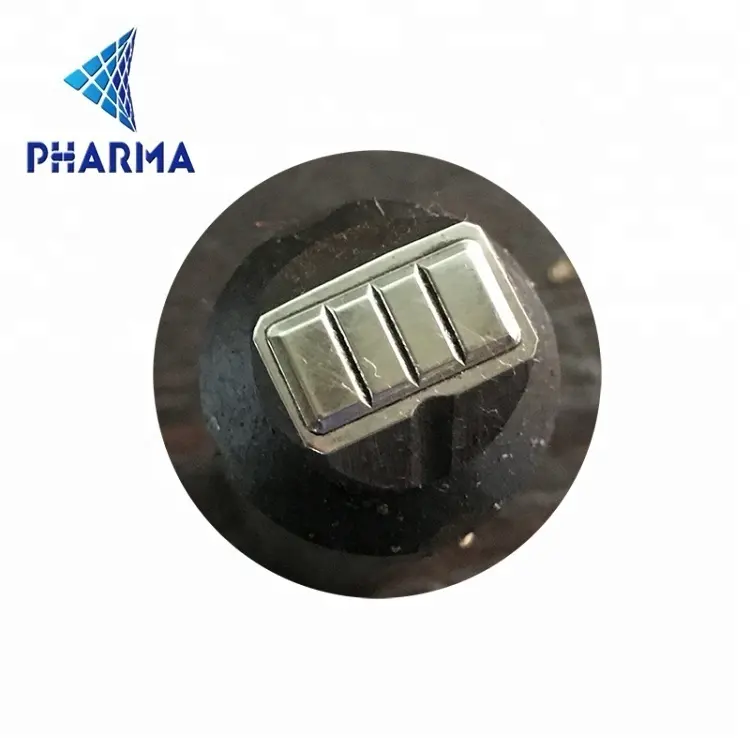

PHARMA Punch And Die metal stamping die vendor for chemical plant

Description:

The die and punch are the most important parts in the tablet press machine, there is one set of die and punch, and they are upper punch, middle punch, lower punch.

Application:

Press Chinese and Western Medicine.

Material | Gcr15 | ||||

Model | ZP   TDP | ||||

Prepare time | 20 working days | ||||

Die size | custom | ||||

TDP single punch tablet press machine in stock

zp12 rotary tablet press machine

New type rotary tablet press gives you better quality and price, automatic tablet press for pressing granular raw materials into. This machine is a single press type, continuous automatic tablet press for pressing granular raw materials into tablets. It is mainly used in pharmaceutical industry and also the chemical, food, electronic, plastic and metallurgical industries.

Tdp Tablet press punch die set

This mold could be used in Manual tablet press machine,TDP-0,TDP-1.5,TDP-5,TDP-6;Rotary tablet press (ZP-5.ZP-7 ZP-9 ZP-10 ZP-12 ZP-15 ZP-19 ZP-23 ZP-29 ZP-33 Etc

Tablet press punches, die, tablet press tooling and tablet press mould

8mm pill press punch die

This mold could be used in Manual tablet press machine,TDP-0,TDP-1.5,TDP-5,TDP-6;Rotary tablet press (ZP-5.ZP-7 ZP-9 ZP-10 ZP-12 ZP-15 ZP-19 ZP-23 ZP-29 ZP-33 Etc

We apply the newest CAD/CAM technology and advanced heat treatment technology and scientific measuring means to machine various kinds of punch and die with high grade bearing steel for tool.