Focuses On Professional Cleanroom Project And Pharmaceutical Cleanroom Equipment.

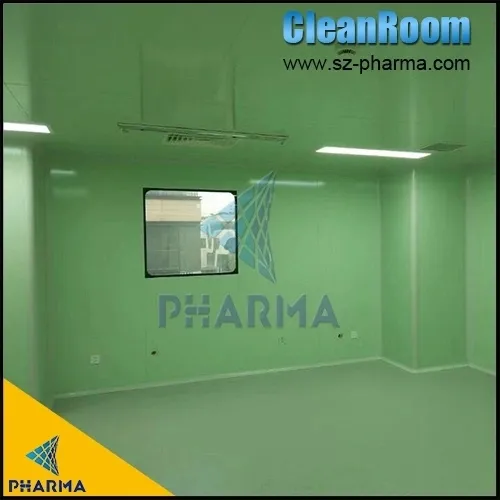

PHARMA pharma clean room in different color for cosmetic factory

After Warranty Service:Video technical support, Online support

Warranty:1 year

Certification:CE ISO GMP

Usage:Beverage Industry

Material:Sandwich panels+ aluminum alloy profile

Ceiling: LED Lighting, Fan filter unit

Clean grade:From Class100-10000

Name:Cleanroom Project

Floor:PVC

Other: Door and windows

Limit Discounts

Description

Beverage aseptic clean room should be isolated from the outside world and should not be crossed or disturbed by other factors.The size of the beverage sterile clean room generally composed of dressing room, buffer room, air shower room and operation room.The changing room is placed outside, mainly for changing clothes, hats, shoes, etc.Buffer between changing clothes and the air shower room, but also at the same time and a few operations interlinked. The operation room(production room) should be placed in the inner room, mainly for product filling. The room should not be exposed to direct sunlight, with appropriate size and height (specific according to the height of the production equipment).Walls should be smooth without dead corners for cleaning and disinfection.

The sterile beverage workshop shall be closed with a positive static pressure difference, and shall be equipped with ultraviolet lamps for air disinfection, air filtration and purifier, and a constant temperature device.

Characteristics 1. The beverage industry has clear provisions on the moving line of personnel and materials,which should not cross flow. Special material transfer port or gate should be set for material flow;Special personnel channel is needed for personnel flow. 2.according to the production process and hygiene, quality requirements, classification of clean level, specific level and requirements. 3. For the liquid processing workshop, special attention should be paid to the stain remaining in the aluminum profile installation caused by washing, which will produce mildew and odor in summer and need special treatment. 4. Personnel hand-washing faucets shall be non-manual (induction, foot or hand lining), and a working boot disinfection pool shall be set when necessary in the production workshop. |

Technical Parameters

| Cleanliness | Class 100 to Class 100000, ISO 5 to ISO 8, Class B to Class D |

| Suspended ceiling | Rock wool sandwich panel, Hollow glass megnesium sandwich panel, T-Grid ceiling, etc |

| Floor | Anti static PVC tile |

| Qualification Documents | IQ, OQ, PQ,DQ |

| Partition | Rock wool sandwich panel, EPS panel, Hollow glass megnesium sandwich panel, etc |

| Temperature&Humidity | As clients request |

| Application | Pharmaceutical Industry LCM, LED, LCD, Electical product, CMOS Camera Module, Touch Play, Optical Module, FILM, Biological Pharmacy, Optoelectronic Display, PCB, Microelectronics, Dust-free coating, Aseptic packaging, Medical care, Auto glass, Precision parts, Food, etc |

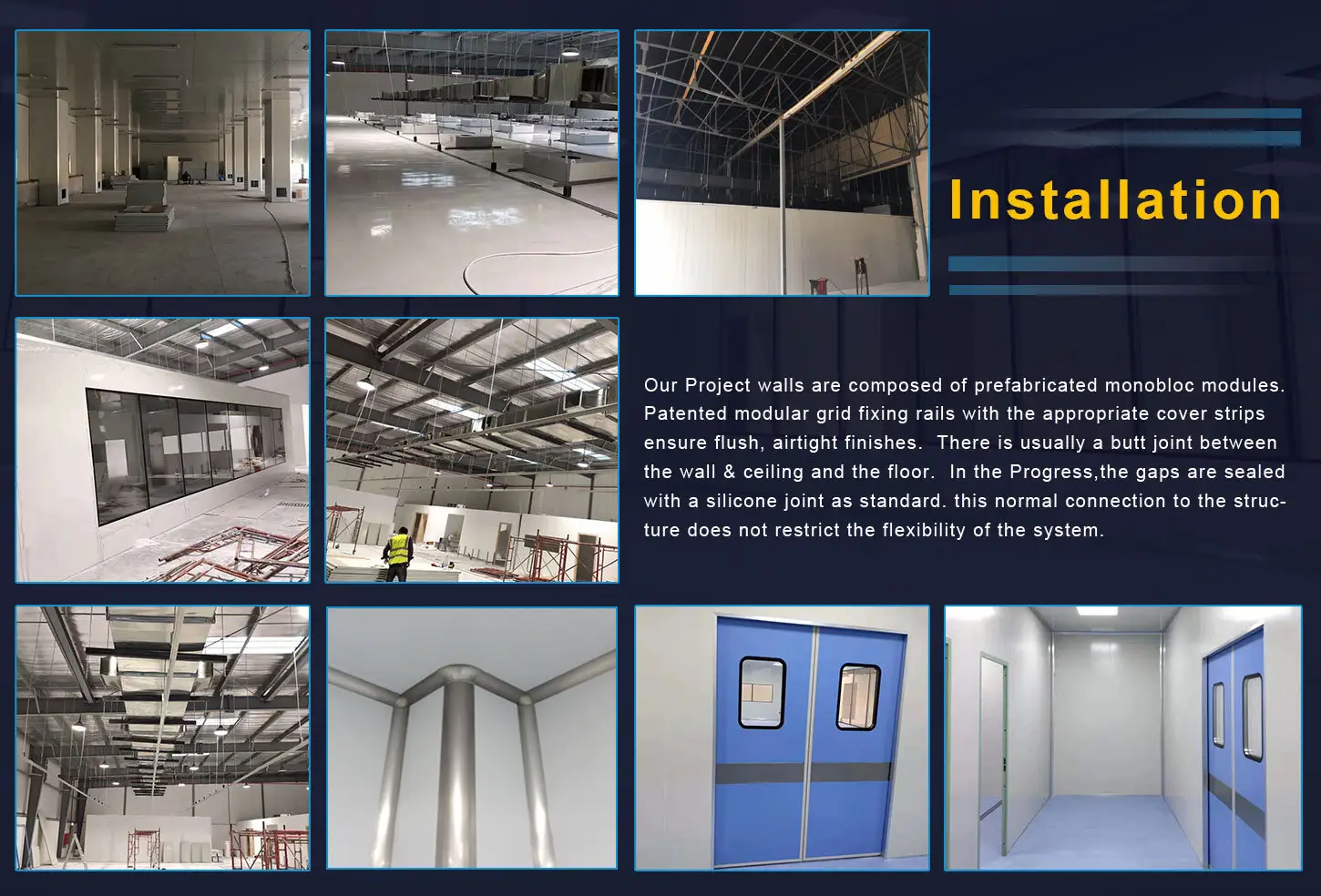

Installation

In order to know your requirement, please fill the following table carefully and supply CAD layout, so that we can provide correct scheme and quotation, thank you!

How to get a quotation >>