Focuses On Professional Cleanroom Project And Pharmaceutical Cleanroom Equipment.

PHARMA pharma clean room experts for herbal factory

1. PHARMA iso 6 cleanroom is designed with high standard. It is designed to meet, tested or compliant with such international standards as IP Protection, UL, and CE.

2. This product actually needs little maintenance. This will reduce the time and cost of maintenance and finally help save production costs.

3. The product has reliable performance and long service life.

4. Because we always adhere to the 'quality first', product quality is fully guaranteed.

After Warranty Service:Video technical support, Online support, Field maintenance and repair service

Warranty:1 year

Certification:CE ISO GMP

Usage:Hospital, laboratory, food packing, liquid filling

Floor:PVC

Lighting:LED

Clean grade:From Class100-10000

Name:Cleanroom Project

Power Supply:200~380V

Material: Sandwich panels, connection parts

Limit Discounts

Description

A Cleanroom or clean room is an environment, typically used in manufacturing or scientific research, that has a low level of environmental pollutants such as dust, airborne microbes, aerosol particles and chemical vapors. More accurately, a cleanroom has a controlled level of contaimination that is specified by the number of particles per cubic meter at a specified particle size. To give perspective, the ambient air outside in a typical urban environment contains 35,000,000 particles per cubic meter in the size range 0.5um and larger in diameter, corresponding to an ISO9 cleanroom, while an ISO1 cleanroom allows no particles in that size range and only 12 particles per cubic meter of 0.3um and smaller. It's suitable for water treatment system, liquid filling machine, tablet production line, pharmaceutical machine, oil extraction line, etc

Characteristics 1. Clean room is a special designed room to exclude the particles in the air, bacteria and other harmful air pollutants 2. the indoor temperature, cleanliness, interior pressure, air velocity and air distribution, noise, vibration, and lighting, static control within the scope of a certain demand. 3. That is no matter how the outside air conditions change, its indoor all can maintain the original set requirements of cleanliness, temperature and humidity and pressure performance characteristic. |

Technical Parameters

| Cleanliness | Class 100 to Class 100000, ISO 5 to ISO 8, Class B to Class D |

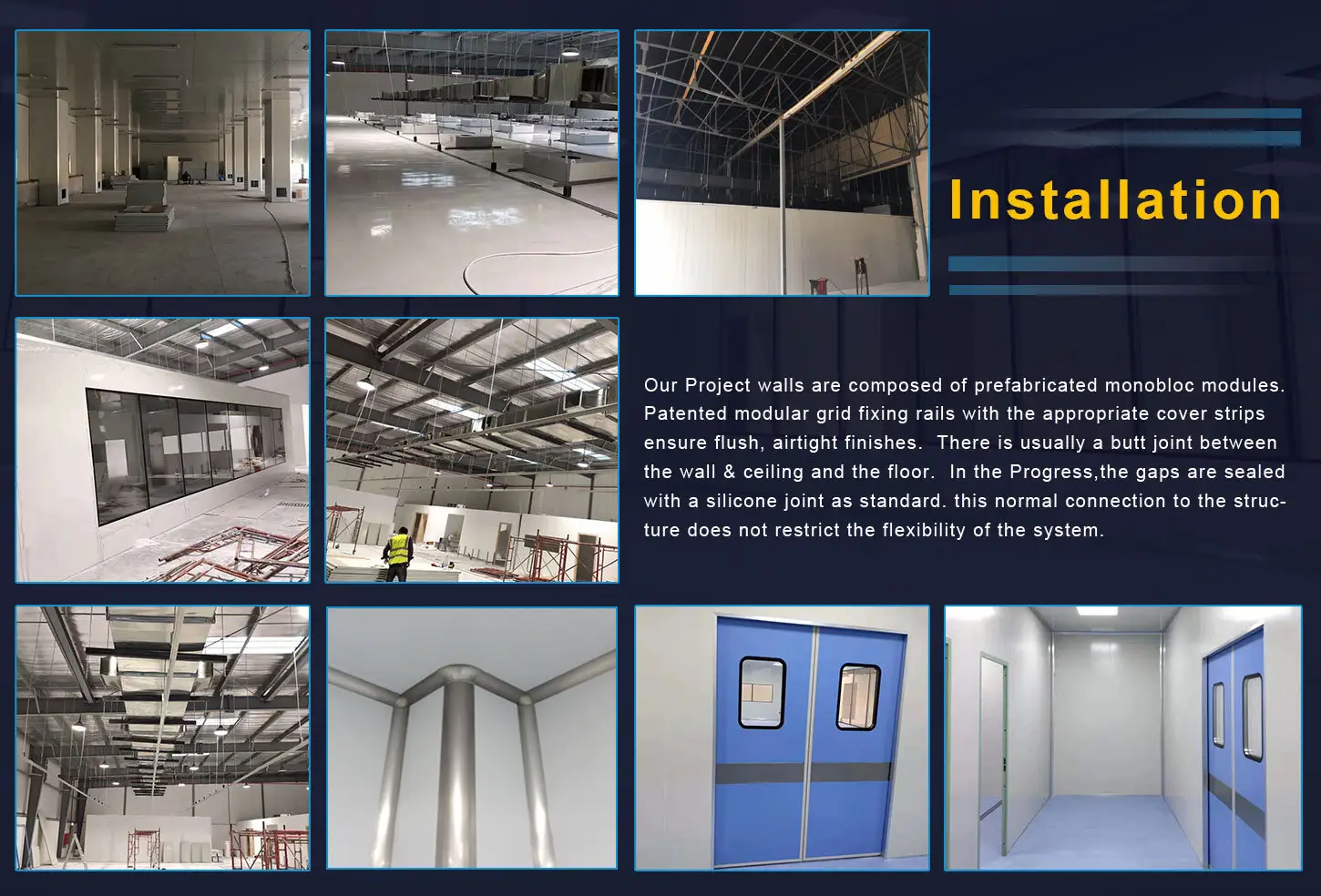

| Project include | 1. Structure: Wall Panel, Ceiling Panel, Windows, Doors, Various Fittings, Flooring |

| 2.Electric: Lighting, Switch, Cables, Wires, Power Distribution Cabinet, etc | |

| 3.HVAC: AHU, Ducting, Piping, Chiller, dehumidifier, etc. | |

| 4.Auto-control: PLC Controller, Sensors for Humidity and Temperature, Control Panel | |

| 5. Process Piping System: Gas, Water Pipeline | |

| Temperature&Humidity | As clients request |

| Application | Pharmaceutical Industry |

| Qualification Documents | IQ, OQ, PQ,DQ |

| Our Service | Professional Consultation, User-friendly English Sofaware, 24 hours technical support,Foreign installation and commissioning |

Installation

In order to know your requirement, please fill the following table carefully and supply CAD layout, so that we can provide correct scheme and quotation, thank you!

How to get a quotation >>

Company Features

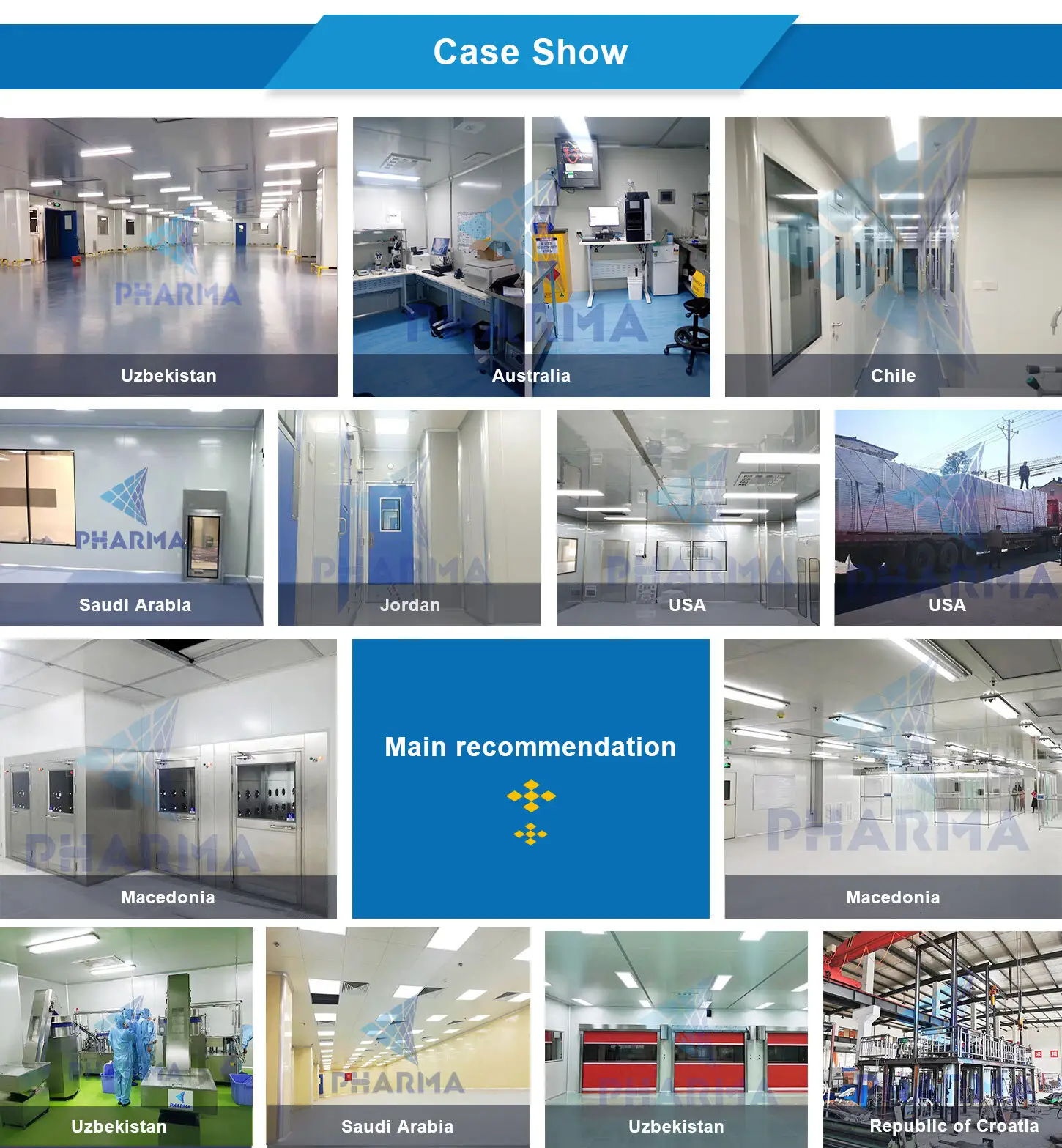

1. SUZHOU PHARMA MACHINERY CO.,LTD. has advanced detection technology and complete quality control system.

2. Our company adopts sustainable manufacturing practices to reduce our GHG emissions; enhance our brand image; gain a competitive edge; and build trust among the investors, regulators, and customers.