Focuses On Professional Cleanroom Project And Pharmaceutical Cleanroom Equipment.

PHARMA gmp cleanroom inquire now for pharmaceutical

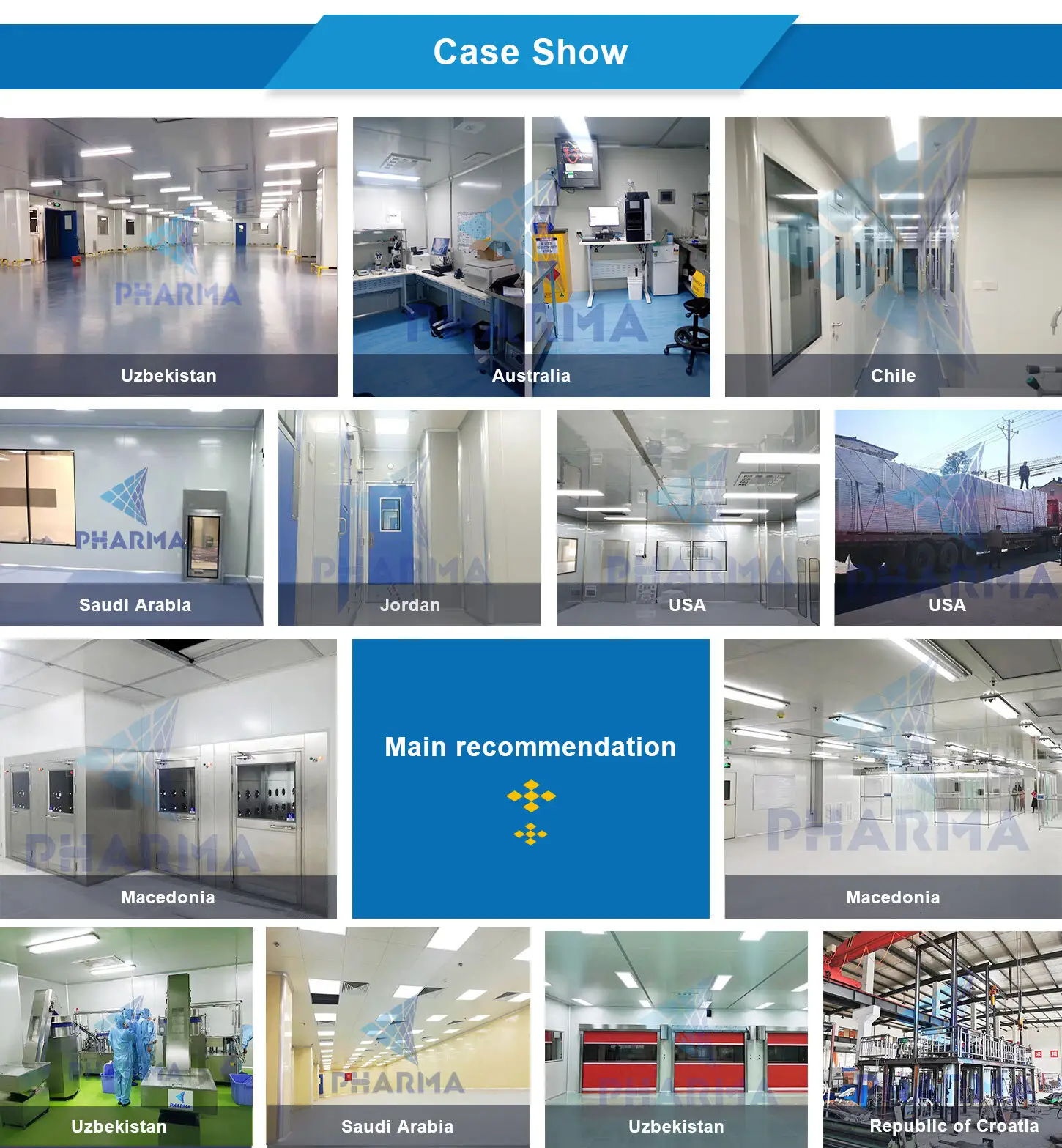

Applicable Industries: Pharmaceutical / medical / electronic

After Warranty Service: Video technical support, Online support, Field maintenance and repair service

Warranty: 1 year

After-sales Service Provided: Online support

Certification: CE ISO GMP

Usage: Hospital/Pharmacy/Medical

Floor: PVC

Lighting: LED

Clean grade: From Class100-10000

Name: Cleanroom Project

Power Supply: 200~240V

Application: Pharmaceutical / medical / electronic

Limit Discounts

Description

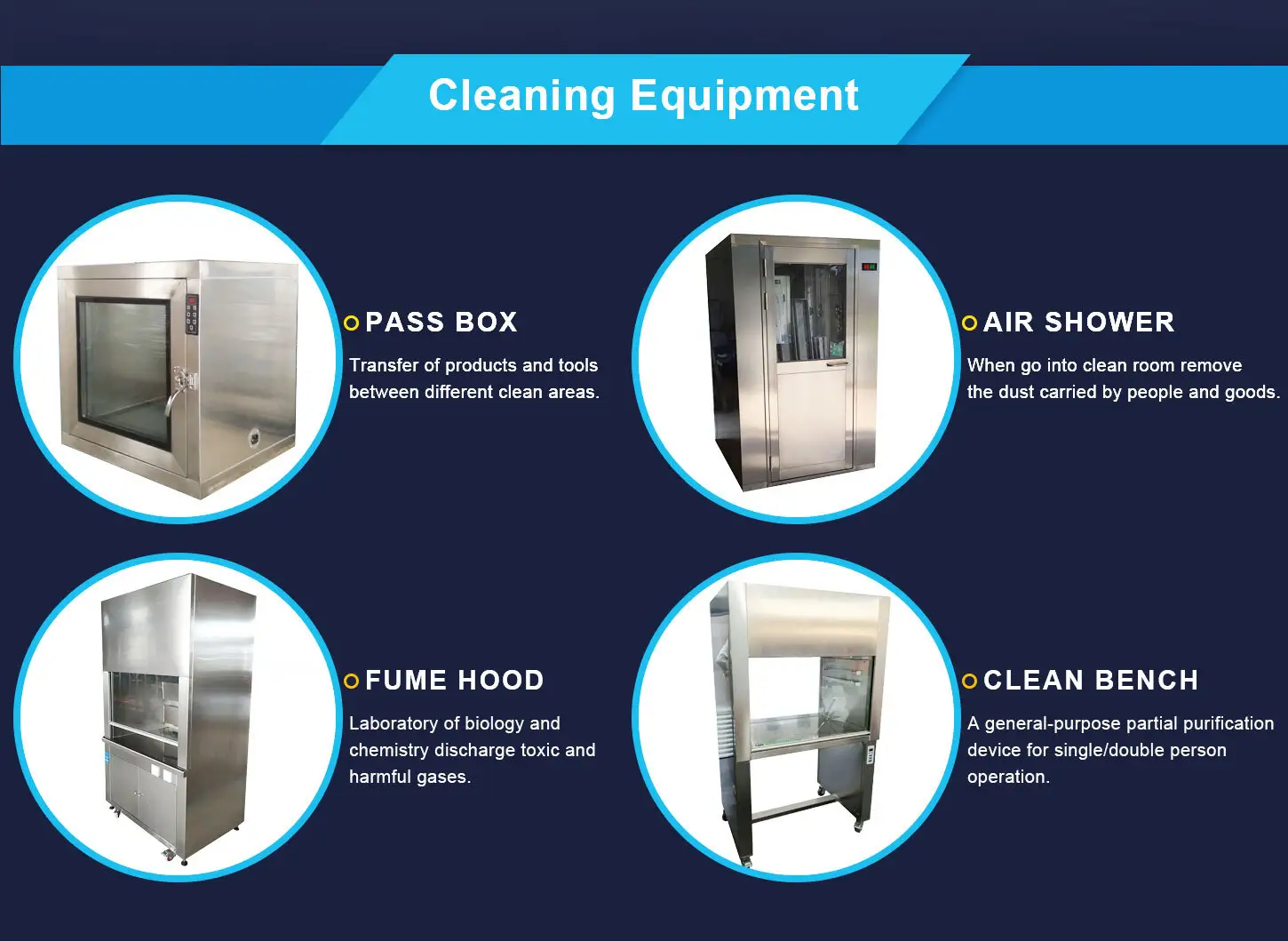

This is a clean room full service construction under GMP request. Turnkey project.

The clean workshop is also called the dust free workshop, the clean room and the dust free room. It refers to the removal of pollutants such as particles, harmful air and bacteria in the air within a certain space, and the indoor temperature, cleanliness, indoor pressure, air velocity and air distribution, noise and vibration, lighting and static control. A specially designed room for a particular requirement. That is to say, no matter how the external air conditions change, the room can maintain the characteristics of cleanliness, temperature and humidity and pressure.

The development of clean room is closely related to modern industry and advanced technology. As a result of medical, food industry, precision machinery industry (such as gyroscopes, micro bearings processing), semiconductor industry (such as large-scale integrated circuit production), such as the requirements of the environment, promote the development of clean room technology.

Characteristics 1. All functions to meet the needs of surgery. 2. It is required to keep the aseptic environment as close as possible to reduce wound infection. 3. It is required to create the most comfortable environment for medical staff to work. 4. Adopt primary and high-efficiency two-stage filtration system, with partition high-efficiency filter, with filtration efficiency of 99.99%ensuring purification level. 5. The wind speed at the air outlet of the air nozzle is more than 25m/s, and the wind speed to the human body is more than 18m/s. |

Technical Parameters

| Cleanliness | Class 100 to Class 100000. ISO 5 to ISO 8. Class B to Class D |

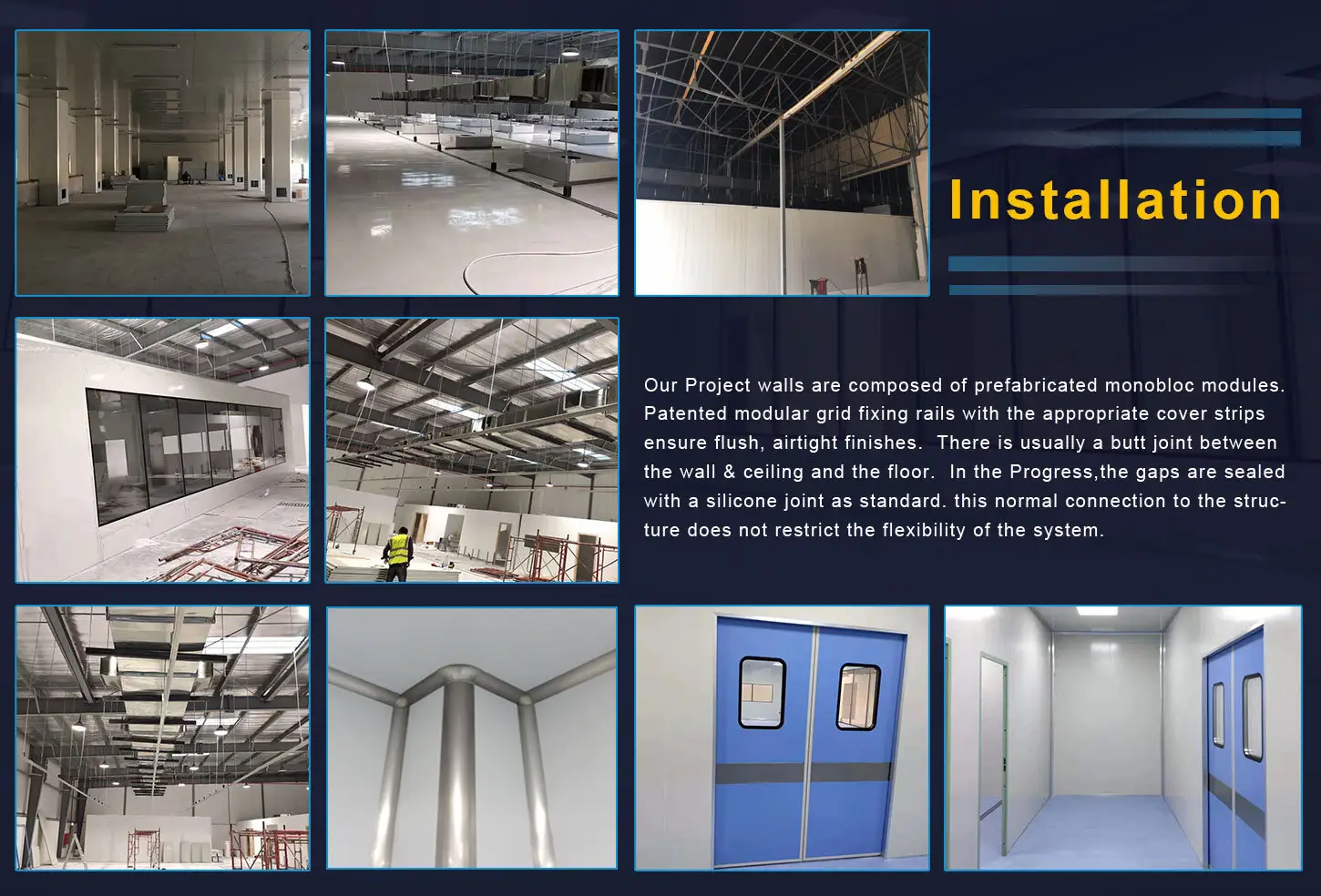

| Project include | 1. Structure: Wall Panel, Ceiling Panel. Windows, Doors, Various Fittings, Flooring 2. Electric: Lighting. Switch, Cables, Wires, Power Distribution Cabinet, etc. 3. HVAC: AHU, Ducting, Piping, Chiller, dehumidifier, etc. 4. Auto-control: PLC Controller. Sensors for Humidity and Temperature, Control Panel. 5. Process Piping System: Gas, Water Pipeline. |

| Temperature&Humidity | As clients request |

| Application | Pharmaceutical Industry |

| Qualification Documents | IQ. OQ. PQ.DQ |

| Our Sen/ice | Professional Consultation, User-friendly English Sofa ware, 24 hours technical support,Foreign installation and commissioning |

Installation

In order to know your requirement, please fill the following table carefully and supply CAD layout, so that we can provide correct scheme and quotation, thank you!

How to get a quotation >>