Focuses On Professional Cleanroom Project And Pharmaceutical Cleanroom Equipment.

PHARMA environmental pharmacy clean room free design for herbal factory

1. PHARMA iso class 8 cleanroom standards conforms to the product design specifications.

2. SUZHOU PHARMA MACHINERY CO.,LTD. keeps improving quality of pharmacy clean room by technology innovation and iso class 8 cleanroom standards .

3. A team of quality people gets the product done quality every time.

4. The product is accurately manufactured to the highest quality standard.

5. The high quality and good usability give the product an edge to compete in the global market.

After Warranty Service:Video technical support, Online support, Field maintenance and repair service

Warranty:1 year

Certification:CE ISO GMP

Usage: Pharmaceutical packaging; foil sealing machine

Floor:PVC

Lighting:LED

Clean grade:From Class100-10000

Name:Cleanroom Project

Power Supply:200~240V

Type:Vertical Flow

Limit Discounts

Description

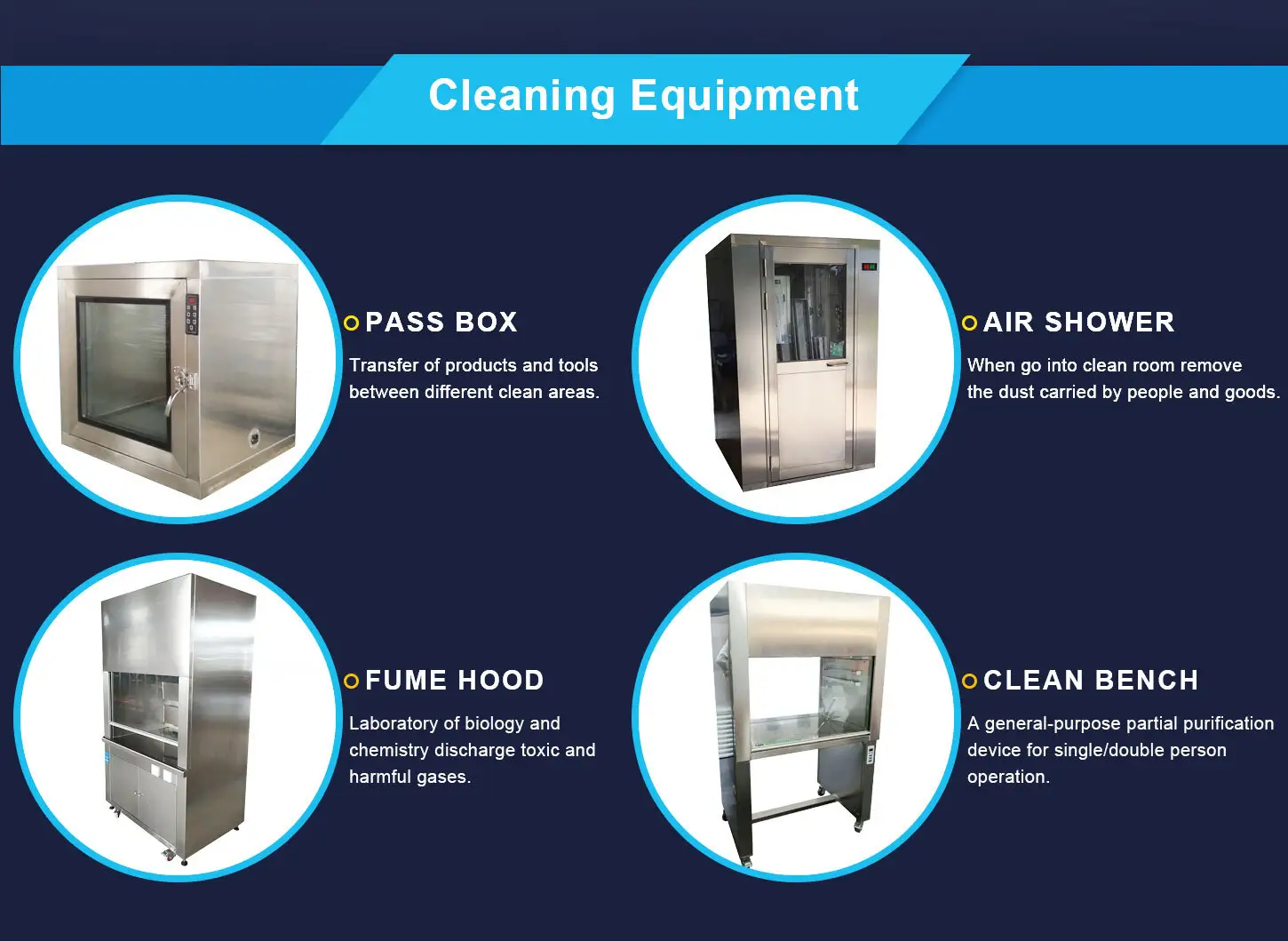

Dust-free clean room refers to the removal of particulates, bacteria and other pollutants in the air in a certain space, and controls indoor temperature, cleanliness, indoor pressure, airflow velocity and airflow distribution, noise vibration and illumination, and static electricity within the scope of demand.

Typically used in manufacturing or scientific research, that has a low level of environmental pollutants such as dust, airborne microbes, aerosol particles and chemical vapors.

Using HEPA and air purification equipment, the dust collection rate reaches 99.97~99.995% full service construction under GMP request.

Principles of the clean room in the pharmaceutical industry

Airflow → primary air treatment → air conditioning → medium effect air treatment → fan air supply → purification duct → high efficiency air supply port → clean room → take away dust (bacteria) → return air duct → fresh air, primary air treatment

Repeat the above process to achieve the purpose of purification.

Characteristics 1. Adopt arc corner which is more suitable for the principle of clean room; 2. The system automatically controls operation, double door electronic interlock, equipped with photoelectric sensor, one-way channel air shower room, entering from the non clean area, infrared induction after the door is closed, the door is locked after the air shower, and only going out of the air shower room from the door; 3. Overall cold-rolled steel plate production, external surface electrostatic spray treatment;4. The door, base plate and nozzle are all made of stainless steel, beautiful and generous; 5. Soft key touch time relay, LED display and setting of shower time, adjustable in the range of 10-99s, double door automatic locking during shower; 6. Adopt primary and high-efficiency two-stage filtration system, with partition high-efficiency filter, with filtration efficiency of 99.99%, ensuring purification level; 7. The wind speed at the air outlet of the air nozzle is more than 25m/s, and the wind speed to the human body is more than 18m/s; 8. EVA sealing material, high sealing performance. |

Technical Parameters

| Level | Name of operating room | Sedimentation (floating) bacteri aMaximum average concentration | Maximum bacterial density on the surface (PCS / cm2) | Air cleanliness level | ||

| Operative area | Peripheral area | Operative area | Peripheral area | |||

| Ⅰ | Special clean operating room | 0.2 / 30min. φ 90 dishes (5 / m3) | 0.4 / 30min · φ 90 dishes (10 / m3) | 5 | Level 100 | Level 1000 |

| Ⅱ | Standard clean operating room | 0.75 / 30min. φ 90 dish (25 /m3) | 1.5 / 30min · φ 90 dishes (50 / m3) | 5 | Level 1000 | Level 10000 |

| Ⅱ | General clean operating room | 2 / 30min · φ 90 dishes (75 /m3) | 4/30min · φ 90 dish (150 / m3) | 5 | Level 10000 | Level 100000 |

| Ⅱ | Quasi clean operating room | 5/30min · φ 90 dish (175 / m3) | 5 | Level 300000 | ||

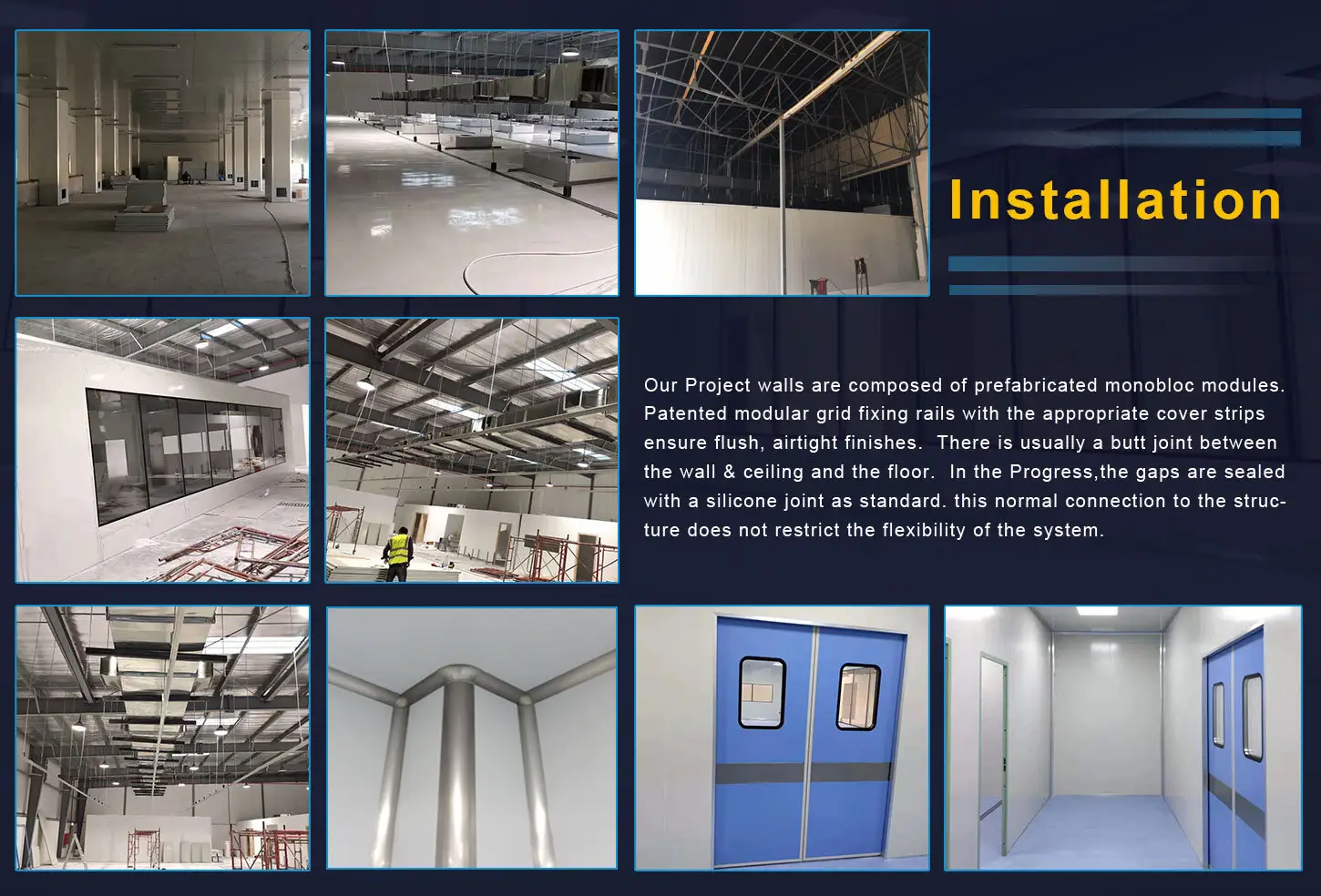

Installation

In order to know your requirement, please fill the following table carefully and supply CAD layout, so that we can provide correct scheme and quotation, thank you!

How to get a quotation >>

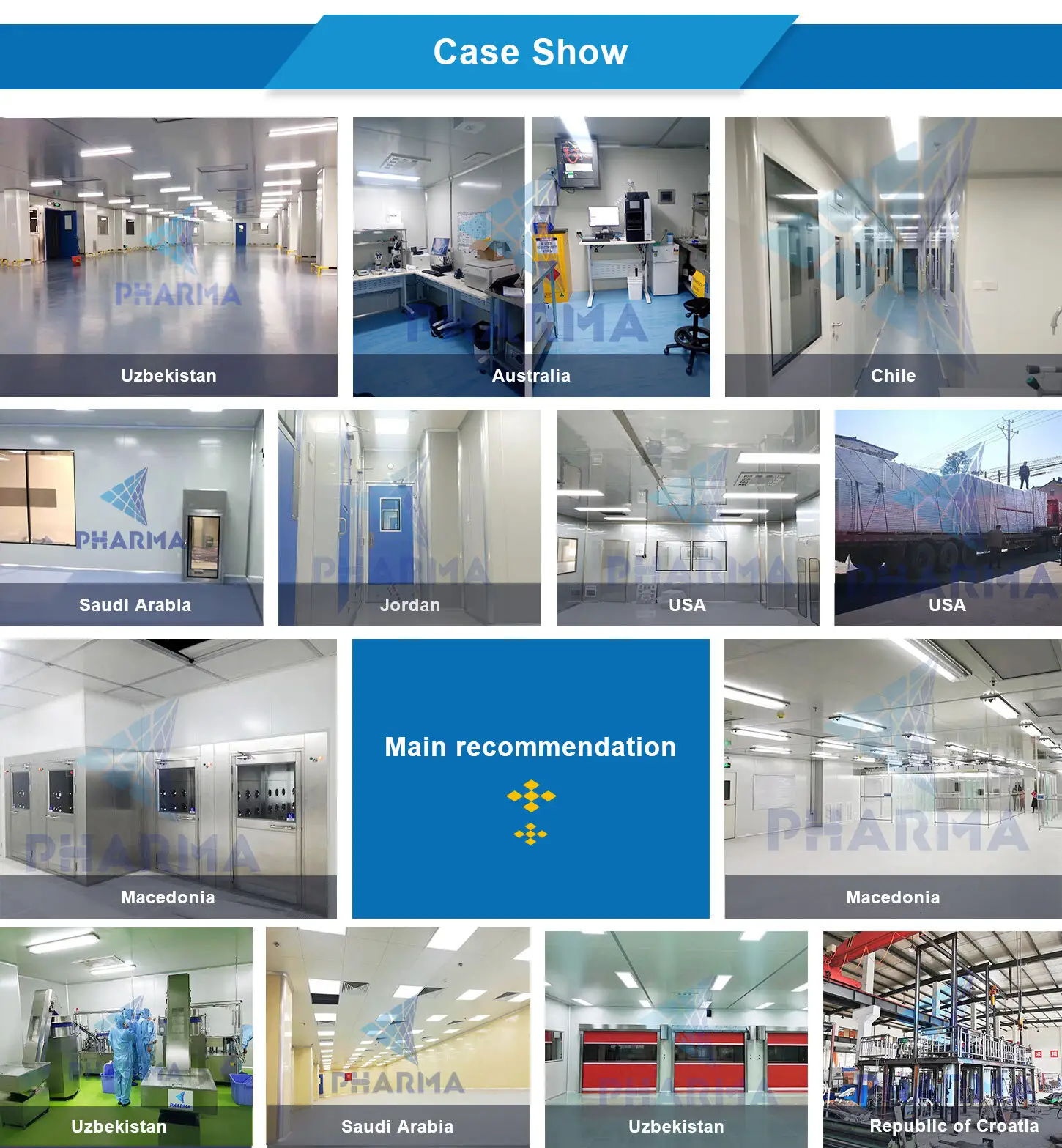

Company Features

1. SUZHOU PHARMA MACHINERY CO.,LTD. is fully committed to pharmacy clean room research and development, production and service. We have a team of professionals who are quite qualified in this field. Our talented design consultant will walk customers through every step of the custom made process to ensure their vision is realized.

2. There are a complete set of latest automatic production facilities and testing equipment that are imported from Japan, the United States, or other countries. These facilities greatly improve production efficiency and meet production demand.

3. With years of channel development, we have established a cooperative relationship with many famous brands and we are forming a large and solid customer base. A keen sense of customer service is an essential value for our company. This value will inspire and guide our daily behavior, encouraging us to make every effort to prioritize and meet the needs of our clients. Get an offer!