Focuses On Professional Cleanroom Project And Pharmaceutical Cleanroom Equipment.

PHARMA custom gmp cleanroom wholesale for herbal factory

1. Bringing the latest idea into designing the gmp cleanroom makes it more attractive.

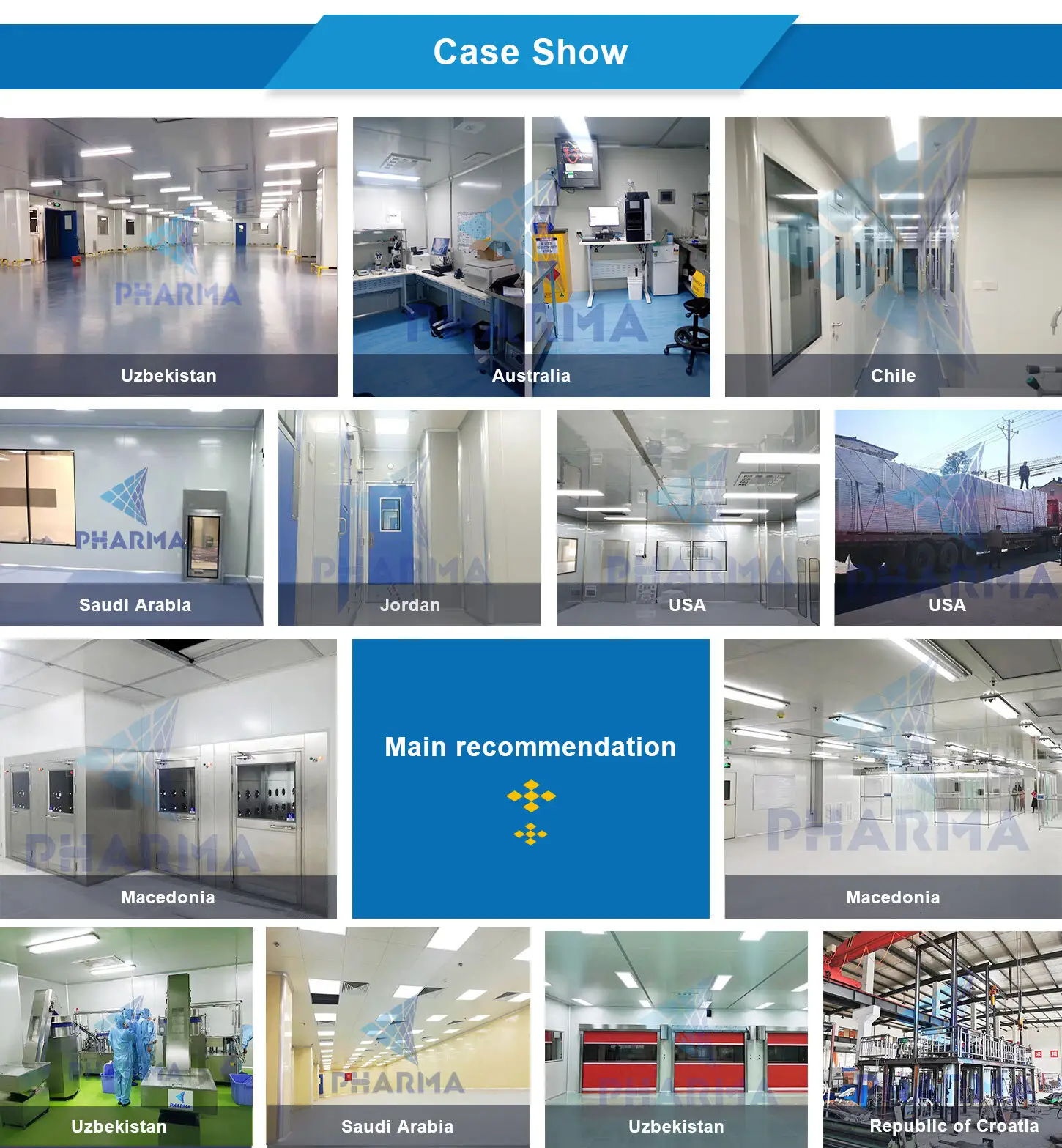

2. This product has been exported to many overseas countries in the world through international marketing channels.

3. Systematic quality control: it is the key control factors in the whole production process. From development to the shipment, the quality of this product is under the whole control of the quality team.

4. Strict quality management system to ensure that products maintain an ideal level of excellence.

5. The product complies with international quality standards.

After Warranty Service:Video technical support, Online support, Field maintenance and repair service

Warranty:1 year

Certification:CE ISO GMP

Usage: Tablet production line;formulation processing

Floor:PVC

Lighting:LED

Clean grade:From Class100-10000

Name:Cleanroom Project

Power Supply:200~240V

Type:Vertical Flow

Limit Discounts

Description

This is a clean room full service construction under GMP request. Turnkey project.

A Cleanroom or clean room is an environment, typically used in manufacturing or scientific research, that has a low level of environmental pollutants such as dust, airborne microbes, aerosol particles and chemical vapors. More accurately, a cleanroom has a controlled level of contaimination that is specified by the number of particles per cubic meter at a specified particle size.

To give perspective, the ambient air outside in a typical urban environment contains 35,000,000 particles per cubic meter in the size range 0.5um and larger in diameter, corresponding to an ISO9 cleanroom, while an ISO1 cleanroom allows no particles in that size range and only 12 particles per cubic meter of 0.3um and smaller.

Airflow → primary air treatment → air conditioning → medium effect air treatment → fan air supply → purification duct → high efficiency air supply port → clean room → take away dust (bacteria) → return air duct → fresh air, primary air treatment.

Repeat the above process to achieve the purpose of purification.

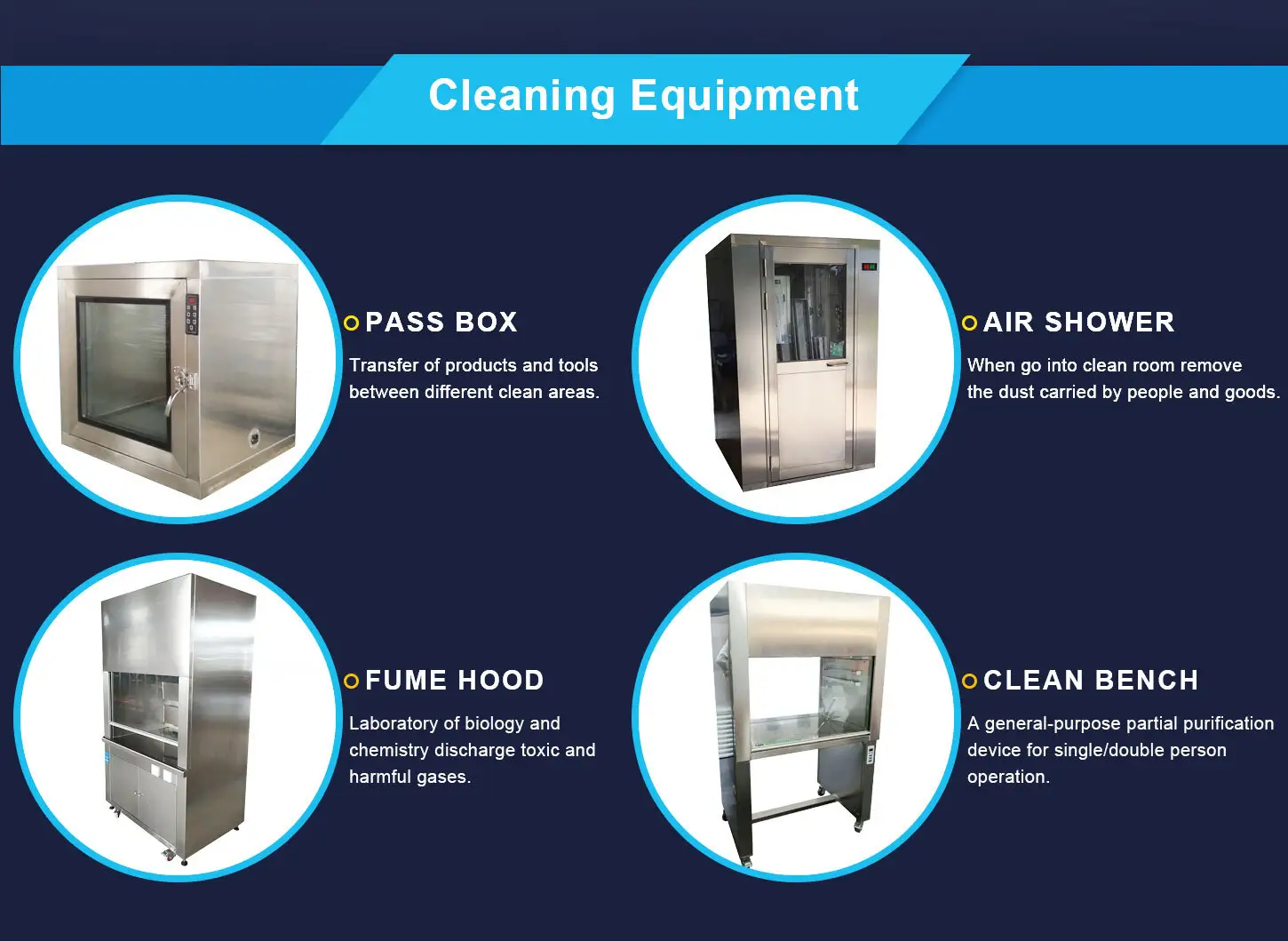

Characteristics 1. Adopt arc corner which is more suitable for the principle of clean room; 2. The system automatically controls operation, double door electronic interlock, equipped with photoelectric sensor, one-way channel air shower room, entering from the non clean area, infrared induction after the door is closed, the door is locked after the air shower, and only going out of the air shower room from the door; 3. Overall cold-rolled steel plate production, external surface electrostatic spray treatment;4. The door, base plate and nozzle are all made of stainless steel, beautiful and generous; 5. Soft key touch time relay, LED display and setting of shower time, adjustable in the range of 10-99s, double door automatic locking during shower; 6. Adopt primary and high-efficiency two-stage filtration system, with partition high-efficiency filter, with filtration efficiency of 99.99%, ensuring purification level; 7. The wind speed at the air outlet of the air nozzle is more than 25m / s, and the wind speed to the human body is more than 18m / S; 8. EVA sealing material, high sealing performance. |

Technical Parameters

| Ventilation frequency | 10-15 times per hour for one hundred thousand level; 15-25 times per hour for ten thousand level; 50-52 times per hour for thousand level; 0.25-0.35m / s for cross-section wind speed of one hundred level operating table. |

| Differential pressure | ≥5Pa for adjacent rooms in the main workshop. |

| Temperature | winter> 16 ℃ ± 2 ℃; summer <26 ℃ ± 2 ℃; |

| Relative humidity | 45-65% (RH); noise ≤65dB (A); |

| Fresh air supply volume | 20% -30% of the total supply air volume; |

| Illumination | ≥300Lux. |

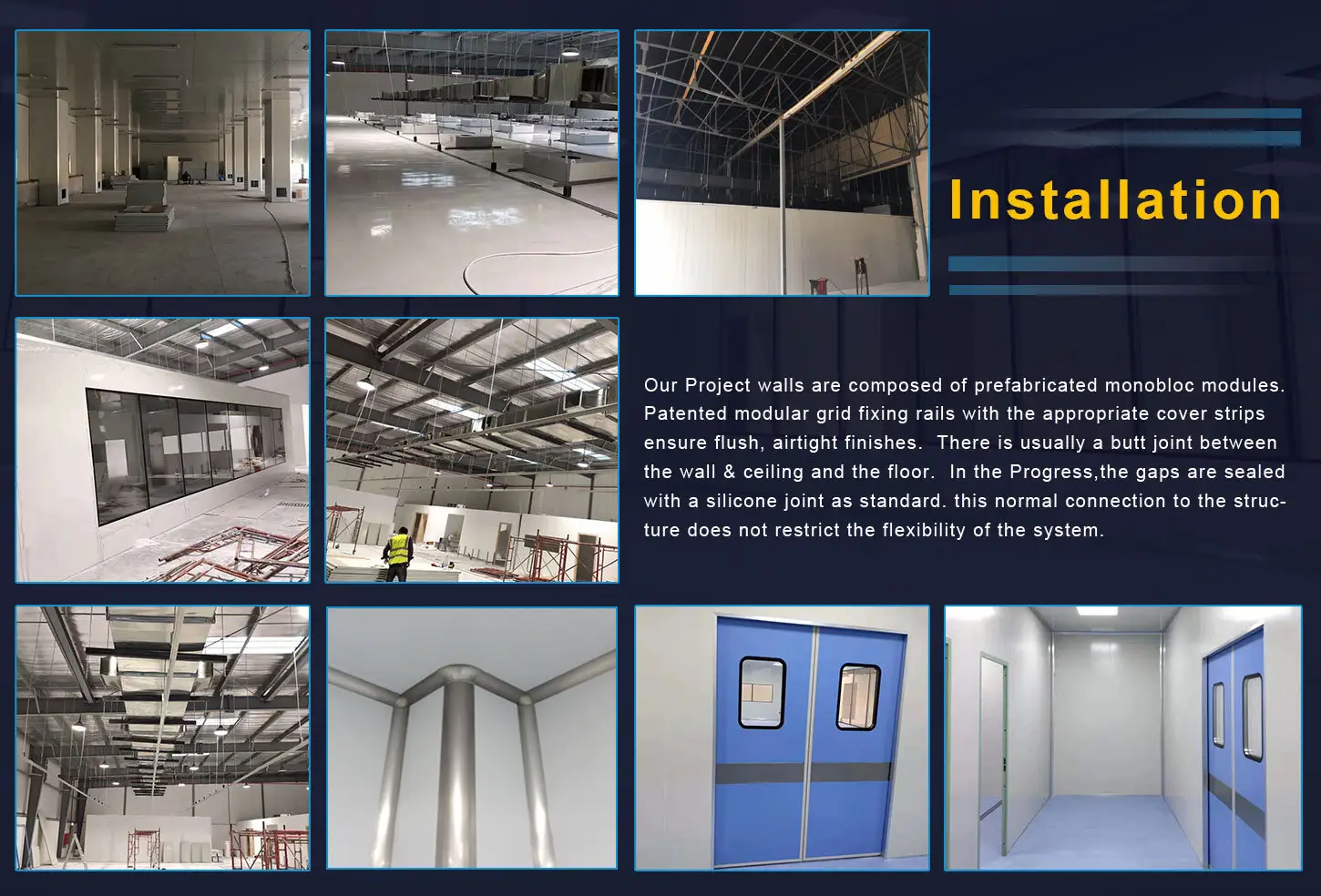

Installation

In order to know your requirement, please fill the following table carefully and supply CAD layout, so that we can provide correct scheme and quotation, thank you!

How to get a quotation >>

Company Features

1. PHARMA keeps optimizing the technology to produce gmp cleanroom.

2. Minimizing the impact on the environment is one of our top priorities. Accordingly, we carefully consider our waste disposal methods. For example, we reuse nearly 100% of the waste in the production process.