Focuses On Professional Cleanroom Project And Pharmaceutical Cleanroom Equipment.

PHARMA custom cleanroom clean room in different color for electronics factory

After Warranty Service:Video technical support, Online support, Field maintenance and repair service

Warranty:1 year

Function: For staff changing cleanroom clothes

Usage: Food, pharmaceutical, medical workshop

Floor: PVC

Lighting: LED

Clean grade:From Class100-10000

Name: Cleanroom changing room

Power Supply: Customize

Clean grade: ISO8/Class D

Limit Discounts

Description

This is a clean room full service construction under GMP request. Turnkey project.

The Cleanroom or clean room is an environment, typically used in manufacturing or scientific research, that has a low level of environmental pollutants such as dust, airborne microbes, aerosol particles and chemical vapors.

More accurately, a cleanroom has a controlled level of contaimination that is specified by the number of particles per cubic meter at a specified particle size.

To give perspective, the ambient air outside in a typical urban environment contains 35,000,000 particles per cubic meter in the size range 0.5um and larger in diameter, corresponding to an ISO9 cleanroom, while an ISO1 cleanroom allows no particles in that size range and only 12 particles per cubic meter of 0.3um and smaller.

GMP classifies cleanrooms/clean areas into four levels: A, B, C, and D. These levels relate to how effective the cleanroom/clean area prevents contamination of the manufacturing and/or processing environment by dust particles and microorganisms.we are a professional manufacturer focus on the clean room and related products.

We can provide best quality and design for you.we also accept customized service.

More details please feel free to contact with us directly.

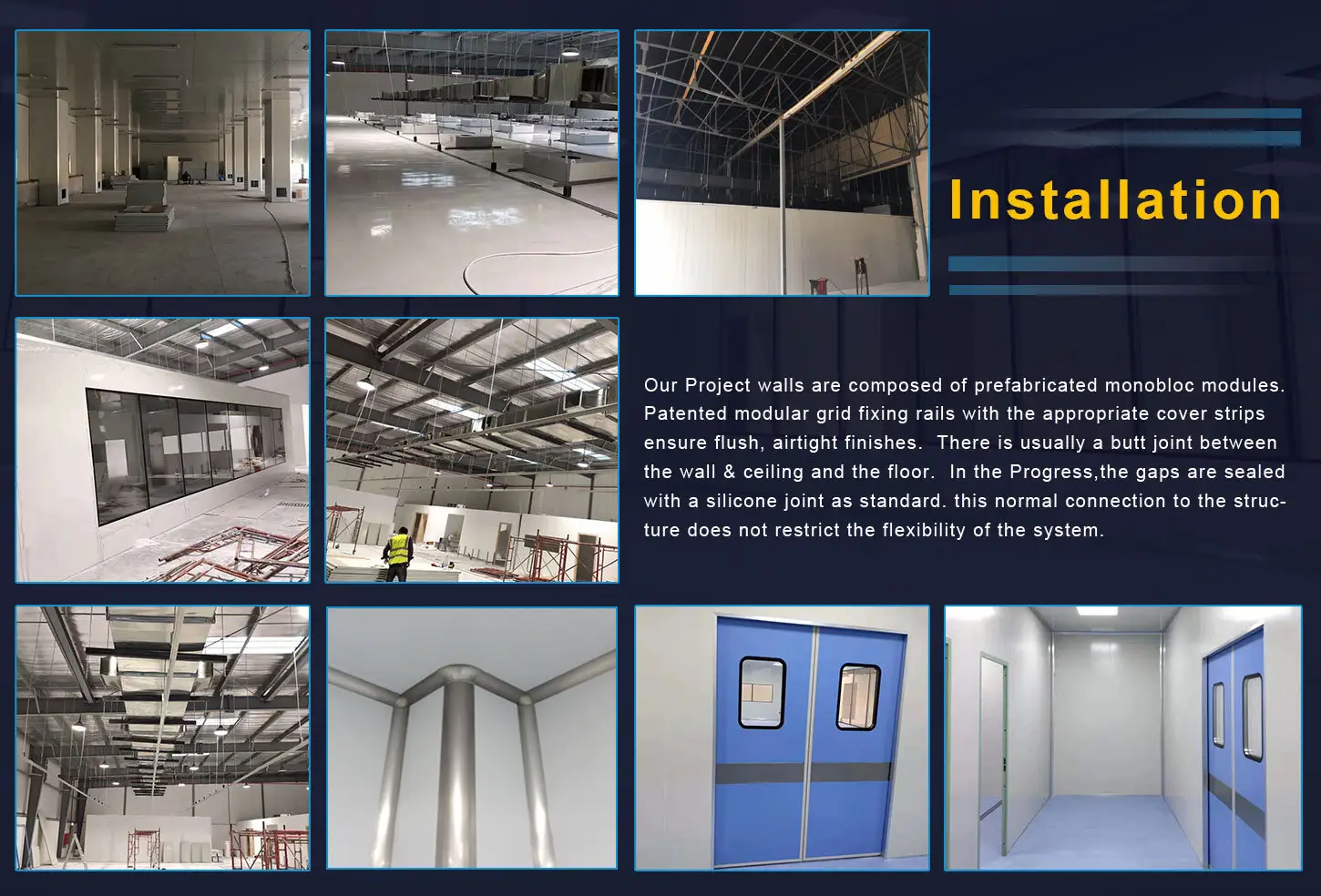

Characteristics 1. Our solid expertise in cleanroom allows meeting the precise needs of its customer's industry in different sectors such as health,pharmaceutical,biotechnology,and cosmetics we firmly believe in the principle of Quality by design. 2.Our Project walls are composed of prefabricated mono-bloc modules. Patented modular grid fixing rails with the appropriate cover strips ensure flush, airtight finishes. 3.The individual wall modules are just clipped together as you proceed. Quite simple and yet very solid. 4.Cleanroom walls can always be customized to meet every need. Module width,module height, height of the glass, cutout sizes, etc.are variable dimensions. 5.GMP double layer glass walls are made entirely of glass. This glass is resistant to almost any chemicals. It neither can be scratched nor dented and adhered dirt can be removed easily. |

Technical Parameters

| Cleanliness | Class 100 to Class 100000, ISO 5 to ISO 8, Class B to Class D |

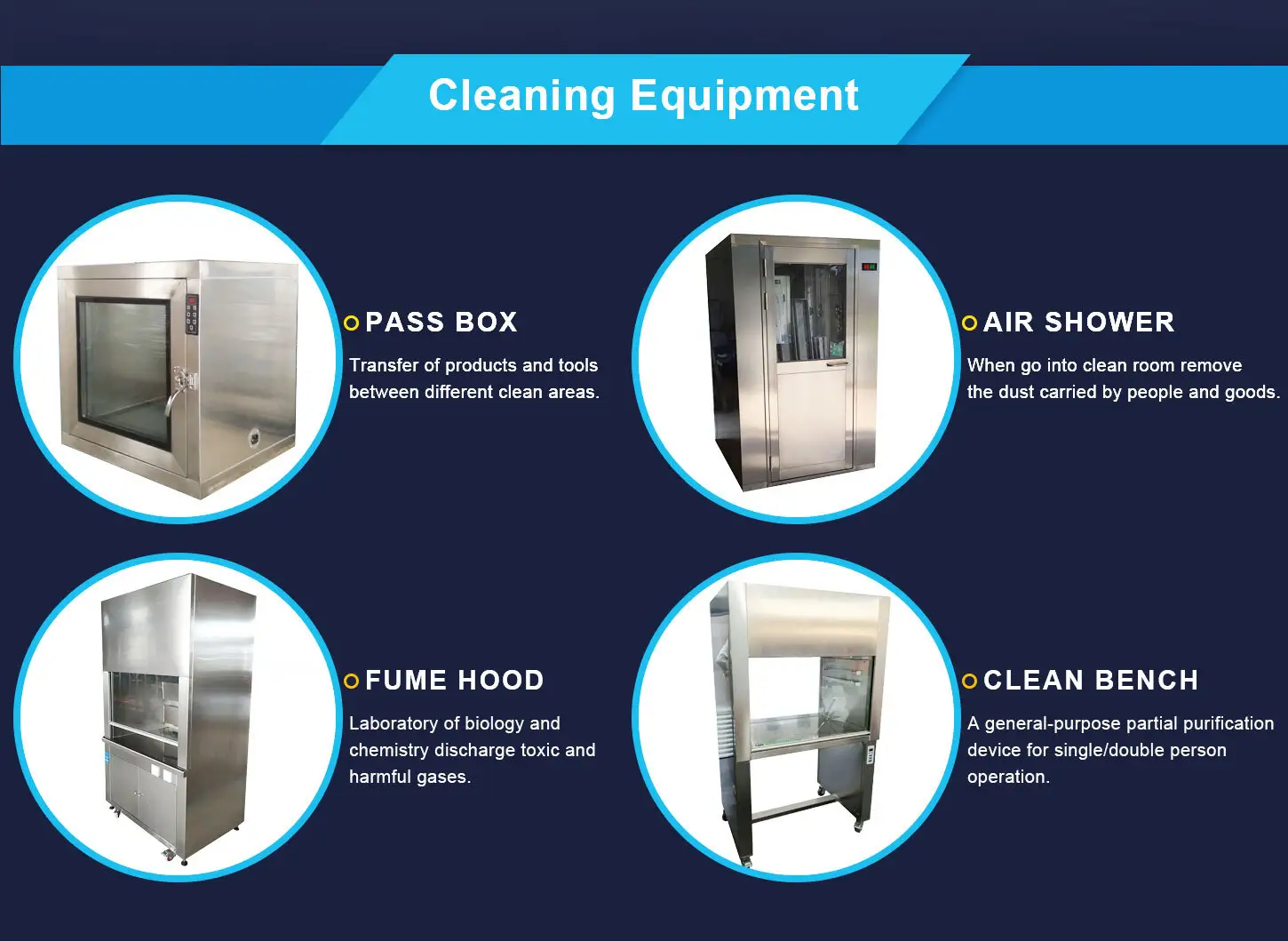

| Project include | 1. Structure: Wall Panel, Ceiling Panel, Windows, Doors, Various Fittings, Flooring |

| 2.Electric: Lighting, Switch, Cables, Wires, Power Distribution Cabinet, etc | |

| 3.HVAC: AHU, Ducting, Piping, Chiller, dehumidifier, etc. | |

| 4.Auto-control: PLC Controller, Sensors for Humidity and Temperature, Control Panel | |

| 5. Process Piping System: Gas, Water Pipeline | |

| Temperature&Humidity | As clients request |

| Application | Pharmaceutical Industry |

| Qualification Documents | IQ, OQ, PQ,DQ |

| Our Service | Professional Consultation, User-friendly English Sofaware, 24 hours technical support,Foreign installation and commissioning |

Installation

In order to know your requirement, please fill the following table carefully and supply CAD layout, so that we can provide correct scheme and quotation, thank you!

How to get a quotation >>