Focuses On Professional Cleanroom Project And Pharmaceutical Cleanroom Equipment.

PHARMA clean room lighting from manufacturer for electronics factory

After Warranty Service:Video technical support, Online support, Field maintenance and repair service

Warranty:1 year

Thickness:0.8mm~2.0mm

Material:6063 Aluminum Alloy

Temper:T5

Deep process:Customized

Application:prefab house, For cleanroom sandwich panel connection use

Length:6m/piece or custom

Used:cleanroom build

Shape:square, round, rectangular, customized

Limit Discounts

Description

The clean room wall structural component belongs to the technical field of clean room. In order to solve the problem that the existing clean room wall structure is complex, the assembly of steel keel frame is troublesome, and the corner of two walls can not be 90 ° dead angle. A clean room wall structural component of the utility model can be modular and fast assembled, and can be firmly inserted without installing steel keel frame, Form an integrated wall structure without dead angle.

Characteristics 1. Solve the problem that the corner of two walls cannot be 90 ° dead angle 2. The new type of corner connector can eliminate the gap and dead angle caused by the joint and smooth transition 3. Fast assembly, without the installation of steel keel frame, can complete the solid insertion, forming an integrated wall structure without dead angle |

Technical Parameters

| Item | Aluminum Profile,aluminium extrusion profiles |

| Material | 6000 series Aluminium alloy |

| Temper | T4, T5, T6 |

| Size / Thickness | General profiles thickness from 0.8 to 5.0mm, length from 3m-6m or customized available; Anodize protection film thickness from 8~25 um, powder coating from 40 ~ 120 um. |

| Shape | square, round, rectangular, customized |

| Surface treatment | Anodized,Mill fninshed,Powder coating,Brushed,Polishing |

| Colors | Customized |

| Deep process | CNC, drilling, milling, cutting, welding, bending, assembling |

| MOQ | 500kgs for each item |

| Packing Details | (1) Inside : packed with plastic protective film to protect each piece (2) Outside: Wrap to be bundles by waterproof craft paper |

| Delivery time | (1) Die Developing and Sample testing: 12-18 days (2) Mass Production completed: 20-30days after sample is confirmed by Buyer. |

| Guarantee | Surface color can be stable for 10~20 years indoor using. |

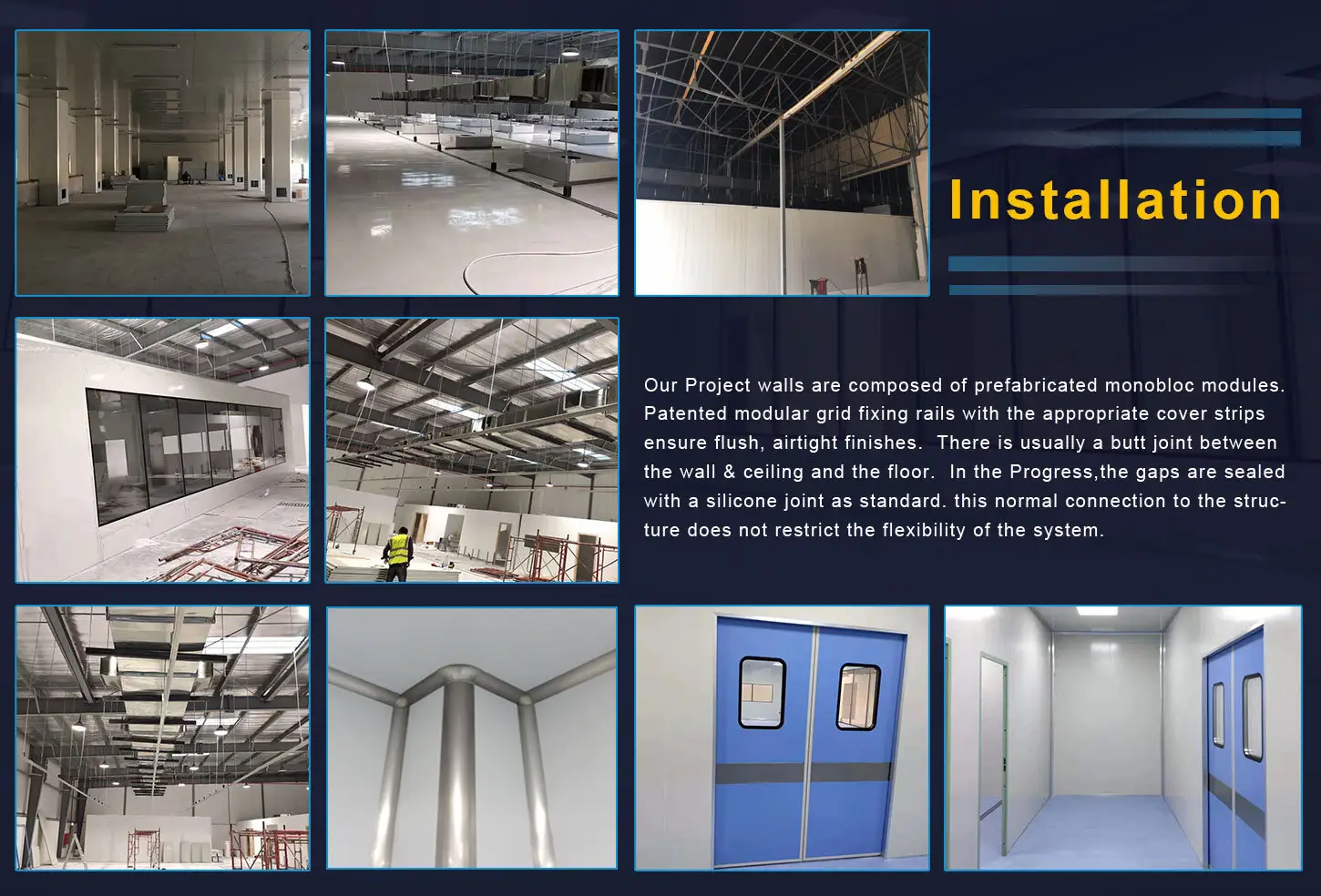

Installation