Focuses On Professional Cleanroom Project And Pharmaceutical Cleanroom Equipment.

newly pharma clean room in different color for pharmaceutical

After Warranty Service:Video technical support, Online support, Field maintenance and repair service

Warranty:1 year

Certification:CE ISO GMP

Usage:Cosmetics Industry

Lighting:LED

Clean grade:From Class100-10000

Name:Cleanroom Project

Floor:PVC

Limit Discounts

Description

Principle of air treatment in cosmetic purification workshop: air flow---secondary air treatment --- air conditioning --- medium air treatment---fan supply air---purification pipe--- high efficiency air supply outlet--- purification workshop;Remove dust (bacteria); In general, 10,000 air purification standards are used in cosmetic processing plants, storage rooms;The laboratory, raw material room, filling room, internal packing disinfection storage room and changing room all adopt 100,000 level air purification standard;The region uses 300,000 air purification standards;It can effectively remove 99.97% of bacteria and dust in the air and ensure that all cosmetics are produced and packaged in a safe and pollution-free environment to ensure good product quality.

Characteristics Design features of cosmetic cleanroom: 1.Reasonably arrange the technological process and building plan; 2. Select building structures and materials that conform to the characteristics of cosmetic cleanrooms; 3. The design of clean rooms for cosmetics should be based on the local energy supply background at that time, and choose reliable and economical 4. Divide and arrange air conditioning purification and exhaust systems; 5. Select proper air purification and ventilation equipment. |

Technical Parameters

| Cleanliness | ISO5toISO8 |

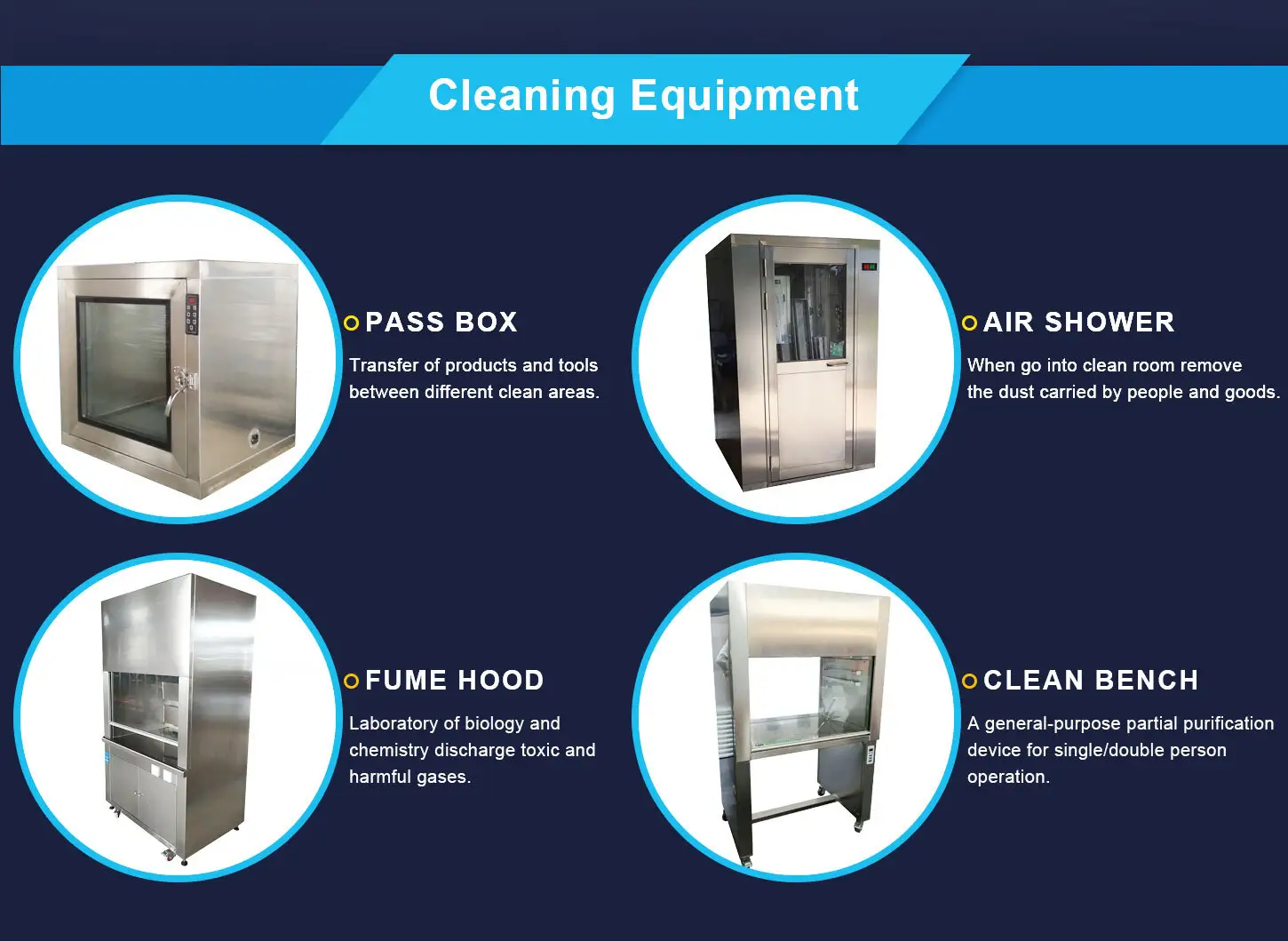

| Project include | Structure: Wall Panel, Ceiling Panel, Windows, Doors, Various Fittings, Flooring HVAC: AHU, Ducting, Piping, Chiller, dehumidifier, etc. |

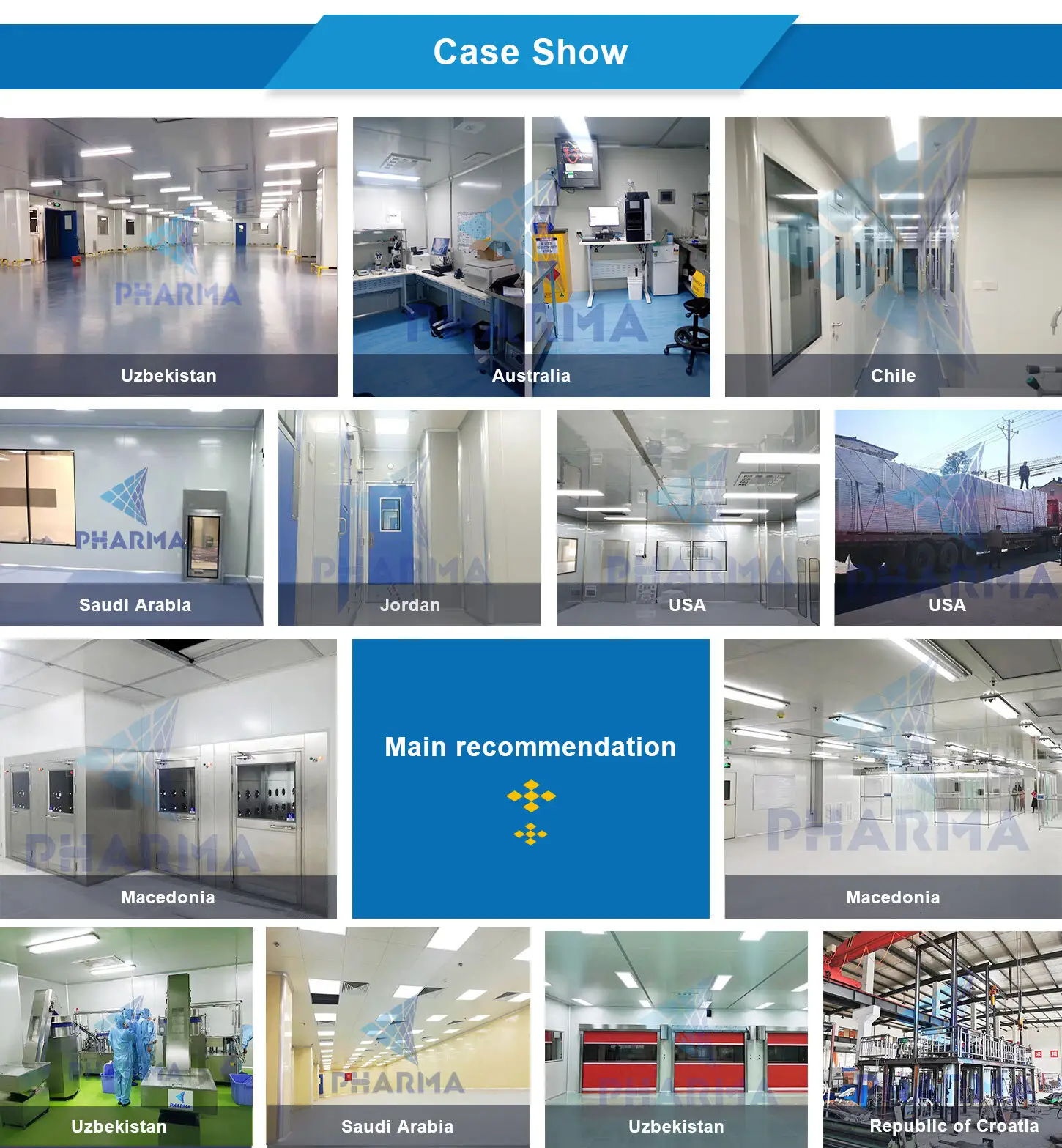

| Application | Biological engineering |

| Our Service | Professional Consultation, User-friendly English Sofaware, 24 hours technical support,Foreign installation and commissioning |

| Temperature&Humidity | As clients request |

| Qualification Documents | IQ, OQ, PQ,DQ |

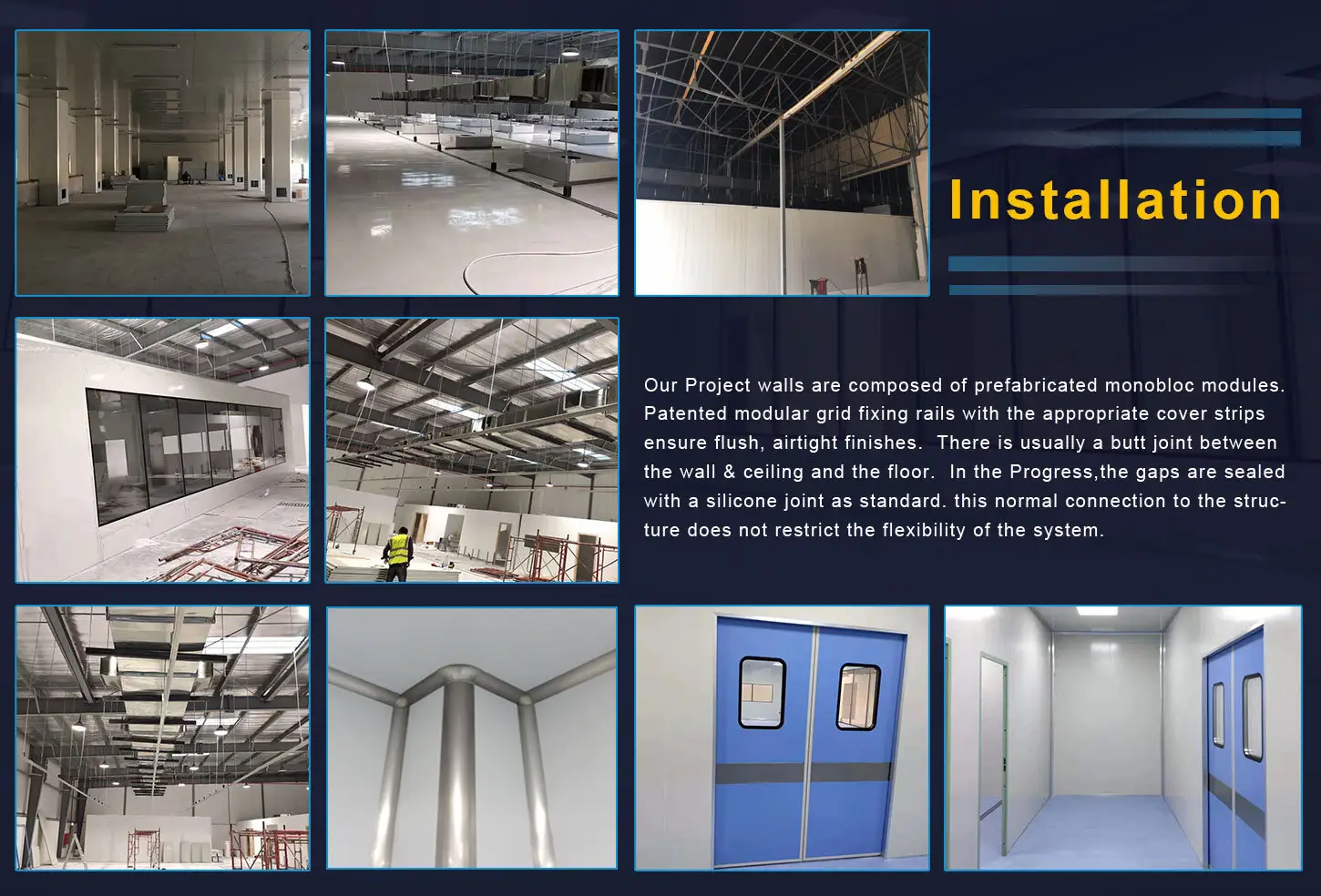

Installation

In order to know your requirement, please fill the following table carefully and supply CAD layout, so that we can provide correct scheme and quotation, thank you!

How to get a quotation >>