no data

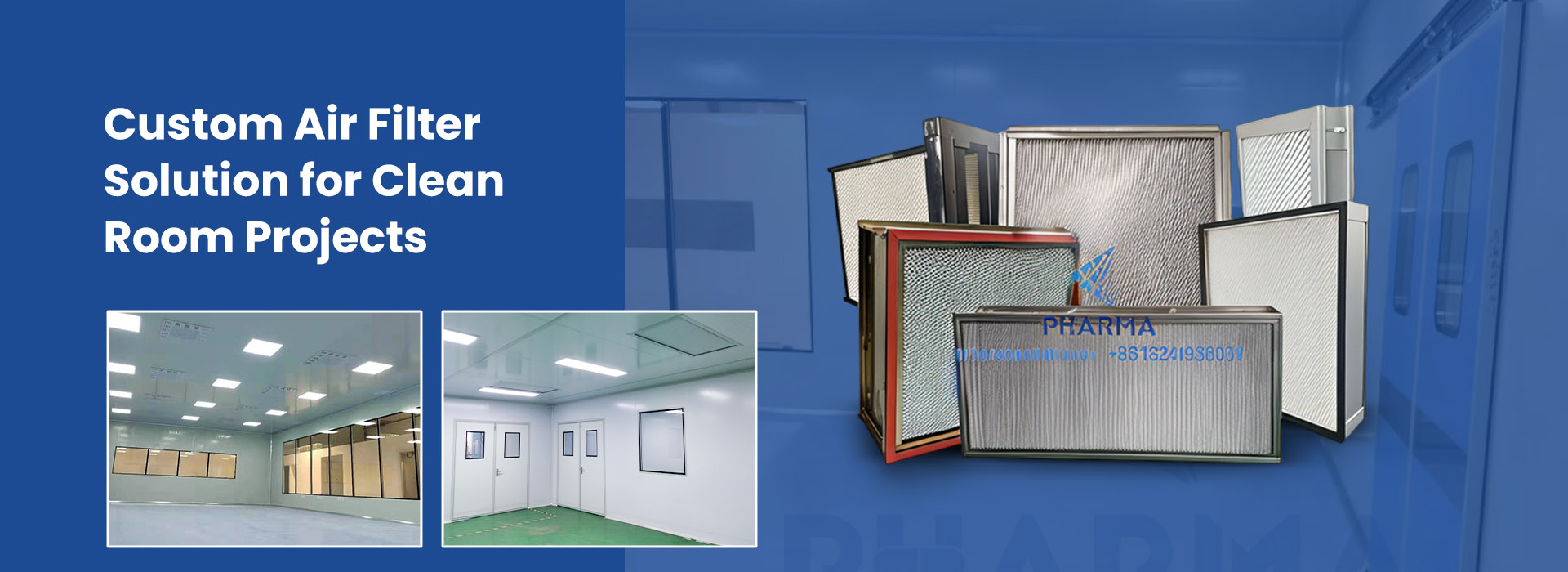

Cleanroom Filters Application

Pharmaceutical air filters device, generally used in clean workshop,laboratory and clean room, or used for dust prevention of electronic machinery communication equipment.

The selection of filters depends on the specific requirements of the clean room class, the industry and location.

High-Efficiency Particulate Air (HEPA) filters:

designed to remove at least 99.97% of particles that are 0.3 micrometers in diameter, which includes most bacteria and viruses.

Ultra-Low Particulate Air (ULPA) Filters:

provide higher levels of filtration efficiency, capturing at least 99.999% of particles as small as 0.1 micrometers.

Pre-Filters: These are typically coarse filters that capture larger particles to protect the more expensive and sensitive HEPA/ULPA filters from rapid clogging.

Activated Carbon Filters: Although not primarily designed for particle removal, they can be included to absorb volatile organic compounds (VOCs) and odors.

Blower Filter Units (BFUs): In some cases, fan-filter units (FFUs) or laminar flow hoods directly integrate HEPA/ULPA filters into their design to create unidirectional airflow patterns critical for maintaining cleanroom standards.

Cleanroom Air Filter Products

Pharmaceutical air filters device: HEPA filters, ULPA Filters, Pre-Filters, Activated Carbon Filters, Blower Filter Units (BFUs), fan-filter units (FFUs) or laminar flow hoods directly integrate HEPA/ULPA filters

no data

Cleanroom Material and Equipment You Can Find In SZ-PHARMA

● Doors

● Panels

● Windows

● Floors

● LED lights

● HEPA box

● Air filters

● Aluminum profiles

● Cleanroom supplies

● Pass box

● Air shower

● HVAC

● Clean bench

● Bio-safety cabinet

● Weighing booth

● VHP isolator

● Fume hood

● Laboratory furniture

industry application

PHARMA CLEAN realizes clean rooms and operates independently and directly throughout the national territory.

no data

why choose us

SZ PHARMA is one of clean room manufacturers has a full experiences team in handling international cleanroom projects and extraction equipment.Sz Pharma as a turn-key project for clean room, pharma, food, herbal, cosmetic, electronics factory and chemical plants. We can offer clean room in pharmaceutical industry and projects as per GMP regulations.

no data

about us

Suzhou Pharma Machinery Co.,Ltd.

Suzhou Pharma is one of the clean room manufacturers & leading turnkey project providers for pharmaceutical, food, herbal, cosmetic,electronics factory and chemical plants. We offer projects as per GMP regulations. As being pioneers in this field, the solutions from Suzhou Pharma is readily accepted by the customers.

Our solid expertise in cleanroom allows meeting the precise needs of its customer's clean room in pharmaceutical industry in different sectors such as health, pharmaceutical, biotechnology, and cosmetics. We firmly believe in the principle of quality by design.

Pharma machinery provide 100% custom design from turnkey cleanroom project to cleaning equipment, pharmaceutical cleanroom equipment and clean rooms extraction machinery. PHARMA CLEAN always maintains an information based relationship with its customers, updating them whenever there is any news in the clean room sector.

certificates

When it comes to your cleanroom certification, we have the qualifications and experienceto deliver a comprehensive validation service off facilities to he requirements of all thecurrent standard and guidelines globally. And our cleanroom are CE Market to show theymeet the requirements of local country directives.

no data

Our Turnkey Cleanroom Case

As an industry leader in purification engineering, Suzhou Pharma is able to provide top solutions for your cleanroom consulting, design, installation, production and maintenance.

no data

Contact Us To Get Competitive Price

Copyright © 2026 Suzhou Pharma Machinery Co., Ltd. | Privacy Policy Sitemap